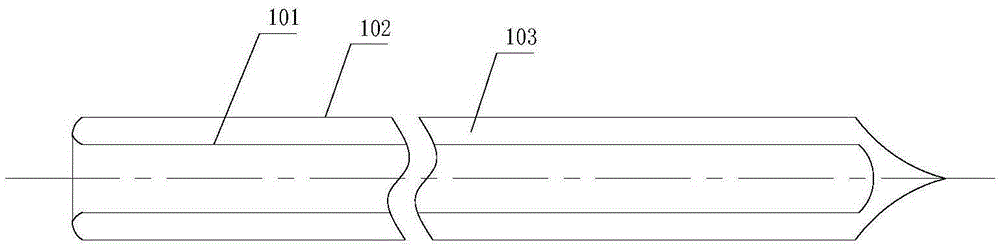

Solar vacuum tube

A technology of vacuum heat collecting tube and solar energy, which is applied in the direction of solar heat collector, solar thermal energy, solar thermal power generation, etc. It can solve the problems of low working reliability, slow rise of water temperature in the tube, and low utilization rate of hot water system, so as to improve thermal efficiency , Increased heat absorption efficiency and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 38 parts of epoxy modified polyurethane resin, 10 parts of dry oil alkyd resin, 8 parts of manganese dioxide, 2 parts of ferric oxide, 2 parts of titanium dioxide, 14 parts of p-xylene, 3 parts of additives, linseed oil 9 parts of acid, 1 part of absorption enhancer, 13 parts of tributyl citrate.

[0024] The prepared coating was sprayed on a degreased zinc plate, and cured at room temperature to form a 5um coating with a solar absorption rate of 0.965 and an emissivity of 0.2.

Embodiment 2

[0026] 40 parts of epoxy modified polyurethane resin, 9 parts of dry oil alkyd resin, 7 parts of manganese dioxide, 4 parts of ferric oxide, 3 parts of titanium dioxide, 13 parts of p-xylene, 4 parts of additives, 8 parts of linoleic acid, 2 parts of absorption enhancer, 10 parts of tributyl citrate.

[0027] The prepared coating was sprayed on a degreased zinc plate, and cured at room temperature to form a 5um coating with a solar absorption rate of 0.975 and an emissivity of 0.15.

Embodiment 3

[0029] 36 parts of epoxy modified polyurethane resin, 7 parts of dry oil alkyd resin, 8 parts of manganese dioxide, 4 parts of ferric oxide, 3 parts of titanium dioxide, 15 parts of p-xylene, 5 parts of additives, 10 parts of linoleic acid, 1 part of absorption enhancer, 11 parts of tributyl citrate.

[0030] The prepared coating was sprayed on a degreased zinc plate, and cured at room temperature to form a 5um coating with a solar absorption rate of 0.962 and an emissivity of 0.18.

[0031] It can be obtained from the above data that the absorption rate of Example 2 is the highest.

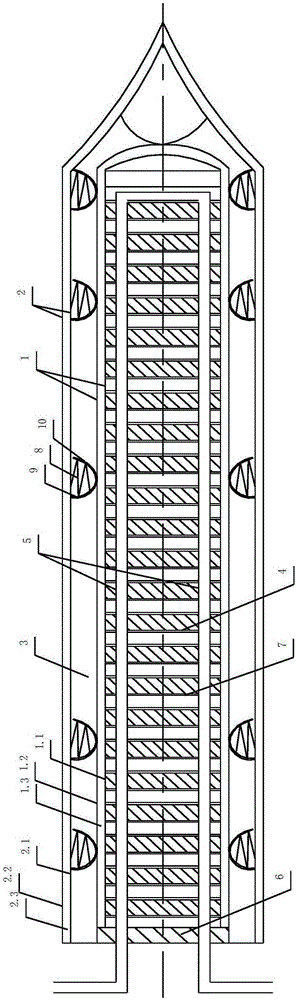

[0032] The multiple heat absorbing plates 4 are parallel to each other; the multiple heat absorbing plates 4 are evenly arranged along the centerline of the inner glass tube 1 .

[0033] A plurality of elastic supports are also provided in the first cavity 3, and the plurality of elastic supports are respectively connected with the inner glass tube 1 and the outer glass tube 2; the plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com