Secondary granulation lithium ion battery cathode material and preparation method thereof

A lithium-ion battery and secondary granulation technology, which is applied to secondary batteries, battery electrodes, circuits, etc., can solve the problems of short cycle life, poor low-temperature performance, and low specific energy density, and achieve excellent rate performance, excellent Low temperature performance and high energy density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

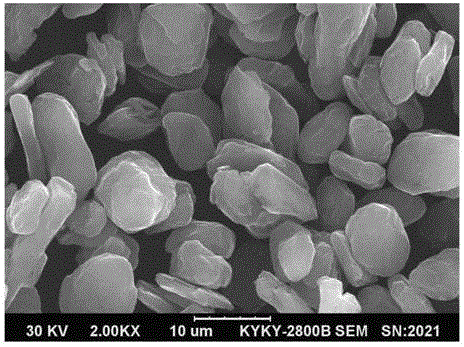

[0025] Use small-sized mesophase carbon microspheres as the substrate, medium-temperature asphalt as the coating and bonding material, and methyl naphthalene as the additive. The mass ratio of the substrate, coating and bonding material, and additive is 60:30:5 , first place the base material and the coating bonding material in a mixer, mix at 100°C for 120 minutes at a speed of 300r / min to obtain a mixed material; put the mixed material into a high-temperature reactor, and pass in argon For protection, react at a speed of 50Hz and a fusion temperature of 500°C for 6 hours to obtain a secondary granulated material; under the protection of argon, transfer the secondary granulated material to the cooling tank, The rotating speed is lowered and cooled to room temperature; and then graphitized heat treatment is carried out at 2800°C to obtain secondary granulated high-voltage lithium-ion battery negative electrode materials. figure 1 It is a 2000 times SEM figure of Example 1 of t...

Embodiment 2

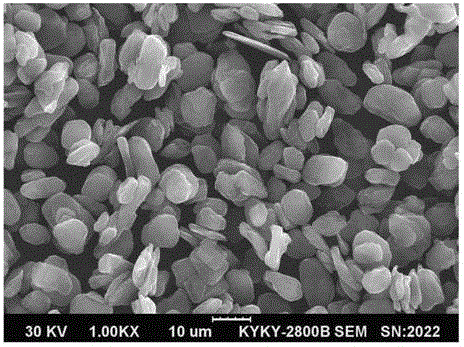

[0027] Petroleum coke is selected as the base material, high-temperature asphalt is selected as the coating bonding material, and methyl naphthalene is used as the additive. The mass ratio of the base material, coating bonding material, and additive is 70:40:4. The material and the coating adhesive material are placed in a mixer, and mixed at 90°C for 100 minutes at a speed of 350r / min to obtain a mixed material; the mixed material is put into a high-temperature reaction kettle, and helium is introduced for protection. The rotating speed of 60Hz and the fusion temperature of 600°C were reacted for 7 hours to obtain the secondary granulated material; under the protection of helium, the secondary granulated material was transferred to the cooling tank, and the temperature was lowered at the rotating speed of 60Hz cooling to room temperature; and then performing graphitization heat treatment at 2700° C. to obtain a secondary granulated high-voltage lithium-ion battery negative ele...

Embodiment 3

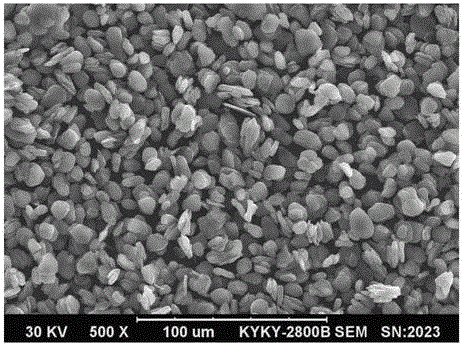

[0029] Select pitch coke as the base material, phenolic resin, etc. as the coating bonding material, and acenaphthene as the additive, and the mass ratio of the base material, coating bonding material, and additive is 80:25:6. Firstly, the base material and The coated bonding material is placed in a mixer, and mixed at 120°C for 140 minutes at a speed of 400r / min to obtain a mixed material; put the mixed material into a high-temperature reaction kettle, and pass in neon gas for protection. Rotational speed, reaction at a fusion temperature of 400°C for 8 hours to obtain a secondary granulated material; under the protection of neon gas, transfer the secondary granulated material to the cooling tank, and cool it down at a rotational speed of 55Hz to room temperature; and then graphitized heat treatment at 2750° C. to obtain secondary granulated high-voltage lithium-ion battery negative electrode materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com