Vegetable protein/soybean polysaccharide nano-emulsion embedding natural fat-soluble pigment and preparation method of vegetable protein/soybean polysaccharide nano-emulsion

A soybean polysaccharide and nanoemulsion technology, which is applied in the fields of polysaccharide/gum-containing food ingredients, food science, and oil-containing food ingredients, etc., can solve the problems of no industrialized production, and achieve short production cycle, simple preparation process, and easy reaction process. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

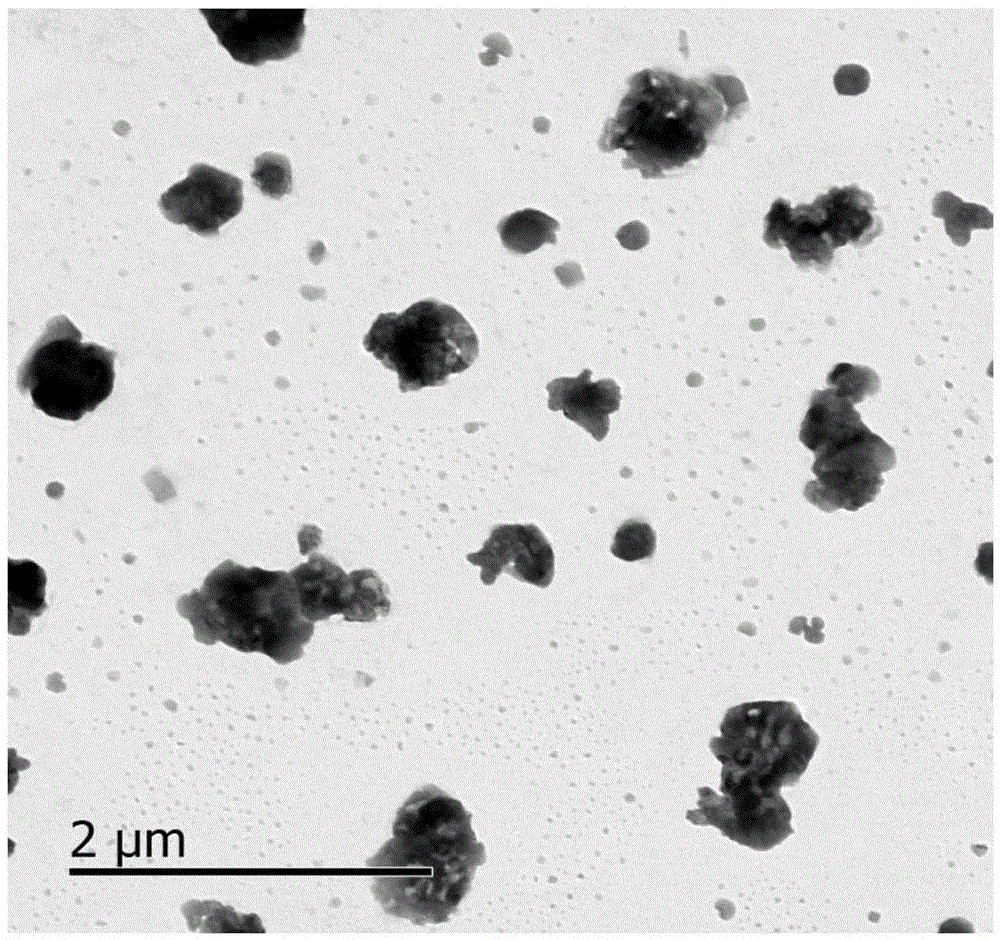

Image

Examples

Embodiment 1

[0031] Dissolve soybean acid-soluble protein and soluble soybean polysaccharide in deionized water respectively, stir for 2 hours, adjust the pH of the solution to 2.0 with a mixed solution of citric acid, malic acid and sodium citrate with a total acid concentration of 0.1mol / L, and obtain protein Storage solution and polysaccharide storage solution, protein storage solution is added in the polysaccharide storage solution and mixed uniformly to obtain a mixed solution, the weight-to-volume ratio of soybean acid-soluble protein in the control mixed solution is 0.5%, and the mass ratio of soybean acid-soluble protein to soybean polysaccharide is 1:1; then dissolve lycopene in corn oil, and add it together with mogroside into the above mixed solution, and control the amount of corn oil added to the mass volume ratio of the mixed solution to be 3g / 100ml, The mass-volume ratio of the amount added relative to the mixed solution is 0.05g / 100ml, stirred at 10000rpm for 1min, and then ...

Embodiment 2

[0033]Dissolve pea acid-soluble protein and soluble soybean polysaccharide in deionized water respectively, stir for 2.5 hours, adjust the pH of the solution to 3.0 with a mixed solution of citric acid, malic acid and sodium citrate with a total acid concentration of 0.1mol / L, and obtain Protein storage solution and polysaccharide storage solution, the protein storage solution is added to the polysaccharide storage solution and mixed evenly to obtain a mixed solution, the weight-to-volume ratio of pea acid-soluble protein in the mixed solution is controlled to be 0.5%, and the mass ratio of pea acid-soluble protein to soybean polysaccharide The ratio is 1:3; then dissolve lycopene in salad oil, and then add it together with mogroside into the above mixed solution. The mass volume ratio of the added amount relative to the mixed solution is 0.05g / 100ml, stirred at 10000rpm for 1min, and then used a high-pressure micro-jet nano-homogenizer to homogenize for 2min at a pressure of 5...

Embodiment 3

[0035] Dissolve kidney bean acid-soluble protein and soluble soybean polysaccharide in deionized water respectively, stir for 3 hours, adjust the pH of the solution to 4.0 with a mixed solution of citric acid, malic acid and sodium citrate with a total acid concentration of 0.1mol / L, and obtain protein Storage solution and polysaccharide storage solution, the protein storage solution is added in the polysaccharide storage solution and mixed evenly to obtain a mixed solution, the weight-to-volume ratio of the kidney bean acid-soluble protein in the control mixed solution is 0.5%, and the mass ratio of the kidney bean acid-soluble protein to soybean polysaccharide is 1:4; then dissolve lycopene in corn oil, add it together with mogroside into the above mixed solution, control the amount of corn oil added relative to the mass volume ratio of the mixed solution to be 3g / 100ml, the amount of lycopene The mass-volume ratio of the added amount relative to the mixed solution is 0.06g / 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com