Ammonium heptamolybdate preparation method and apparatus thereof

A technology for ammonium heptamolybdate and production equipment, applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., can solve problems such as not being able to meet user requirements, achieve low light transmittance, improve quality, and reduce impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

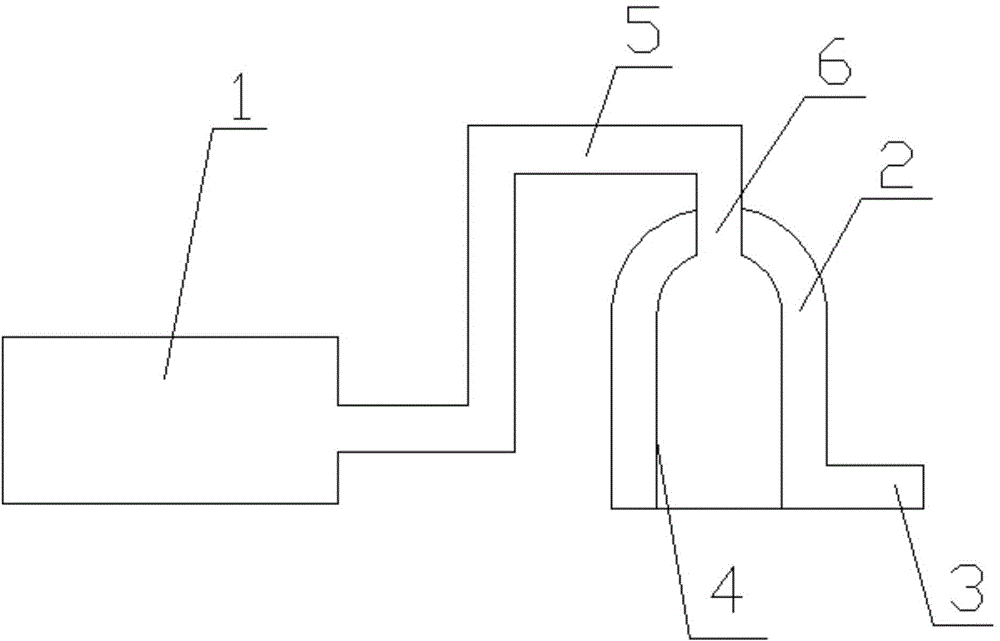

Image

Examples

Embodiment Construction

[0021] The preparation method of ammonium heptamolybdate comprises the steps of pickling, ammonia leaching, sedimentation and impurity removal, acid precipitation and evaporation crystallization:

[0022] Step (1) pickling: take molybdenum oxide: nitric acid = 10:1 ratio, the high-grade molybdenum oxide, wherein the molybdenum content is greater than 55%, the tungstophosphorus lead content is not more than 0.1%; the nitric acid concentration is greater than 98% and Higher purity requirements. Add an appropriate amount of deionized water to the solution, the conductivity of which is lower than 8s, the reaction temperature is ≥95°C, and the holding time is 1.5h to obtain an acid-washed filter cake;

[0023] Step (2) Ammonia immersion: put the acid-washed filter cake into an appropriate amount of deionized water, pass liquid ammonia to ph=9, the concentration of the liquid ammonia is greater than 98%, the reaction temperature is 75°C to 85°C, and the reaction time is ≤2h, pH is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com