Industrial production method for extracting stachyose from radix rehmanniae

A production method, the technology of stachyose, is applied in the field of industrialized production of extracting stachyose from Rehmannia glutinosa, which can solve the problems of complex processing aids, high operating costs, and inapplicability to industrial production, so as to reduce product risk and process aids. The effect of less agent and easy operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

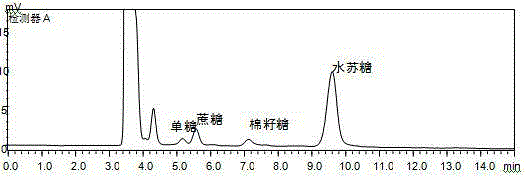

Image

Examples

Embodiment 1

[0024] (1) Juice extraction: according to the mass ratio of 1:6, add water to 200kg of dried raw land slices and extract at 85°C for 1 hour, take the juice, take the residue and continue to extract the juice for 3 times according to the above process, the obtained juice is mixed and then pumped into the sandwich pot;

[0025] (2) Impurity removal: Heat the liquid in the jacketed pot to 70°C, pass through a 200-mesh vibrating screen, and then pump it into a centrifuge to remove impurities;

[0026] (3) Decolorization: pump the centrifuged supernatant into a decolorization tank, heat it to 80°C, add activated carbon powder 10‰ (m / v), diatomaceous earth 3‰ (m / v), and keep warm for 1 hour for decolorization. Pump the decolorized feed liquid into the plate and frame filter for filtration, and the filtrate is introduced into the storage tank;

[0027] (4) Ion exchange: Cool the feed liquid in the storage tank to 20°C, pump the feed liquid into the anion and cation column for decont...

Embodiment 2

[0031] (1) Juice extraction: According to the mass ratio of 1:10, add 400kg of fresh rehmannia glutinosa slices and add water to leaching for 4 hours at 40°C, take the juice, take the residue and continue to extract the juice once according to the above process, and mix the obtained juice Then pump into the jacketed pot;

[0032] (2) Impurity removal: Heat the liquid in the jacketed pot to 45°C, pass through a 200-mesh vibrating screen, and then pump it into a centrifuge to remove impurities;

[0033] (3) Decolorization: pump the centrifuged supernatant into a decolorization tank, heat it to 65°C, add activated carbon powder 40‰ (m / v), diatomaceous earth 8‰ (m / v), and keep warm for 1.5 hours for decolorization. Pump the decolorized feed liquid into the plate and frame filter for filtration, and the filtrate is introduced into the storage tank;

[0034] (4) Ion exchange: Cool the feed liquid in the storage tank to 15°C, pump the feed liquid into the anion and cation column for...

Embodiment 3

[0038] (1) Juice extraction: According to the mass ratio of 1:2, add water to 200kg of dried raw land slices and extract at 90°C for 0.5 hours to extract the juice, continue to extract the juice from the residue according to the above process for 5 times, mix the obtained juice and pump it into the sandwich pot;

[0039] (2) Impurity removal: heat the liquid in the jacketed pot to 85°C, pass through a 200-mesh vibrating screen, and then pump it into a centrifuge to remove impurities;

[0040] (3) Decolorization: pump the centrifuged supernatant into a decolorization tank, heat it to 95°C, add 1‰ (m / v) of activated carbon powder, 1‰ (m / v) of diatomaceous earth, and keep warm for 0.5 hours for decolorization. Pump the decolorized feed liquid into the plate and frame filter for filtration, and the filtrate is introduced into the storage tank;

[0041] (4) Ion exchange: Cool the feed liquid in the storage tank to 30°C, pump the feed liquid into the anion and cation column for dec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com