Color-variable putty powder and preparation method thereof

A putty powder and colorant technology, applied in the field of building materials, can solve the problems that photochromic coatings cannot adapt to high temperature environments, market demands, and cannot be discolored early warning, etc., and achieves easy promotion, good adhesion, and stable quality. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

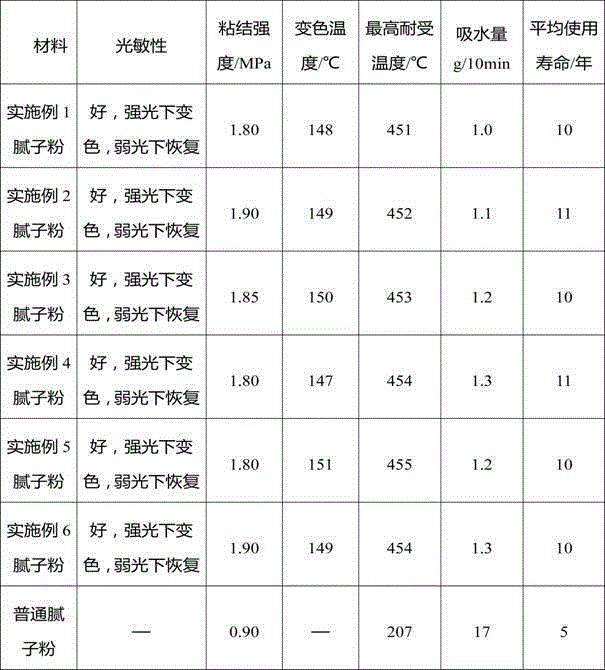

Examples

Embodiment 1

[0029] A kind of photosensitive discoloration putty powder and preparation method thereof

[0030] Composition of color-changing putty powder:

[0031] WO 3 1kg, MoO 3 1kg, TiO 2 1kg, ZnO1kg, dithiopheneethylene 1kg, talcum powder 10kg, diatomaceous earth 20kg, glass microspheres 1kg, barite powder 1kg, SiO 2 1kg, 1kg of mica powder, 40kg of clay, 1kg of cobalt naphthoate-styrene solution with a mass concentration of 6%, 0.5kg of cyclohexanone peroxide, 0.5kg of methyl ethyl ketone peroxide, 1kg of titanium white, and 1kg of glycidyl allyl ether.

[0032] The preparation method is:

[0033] (1) Gelatinization: Weigh talcum powder, diatomaceous earth, glass microspheres, barite powder, SiO 2 , mica powder, clay, glycidyl allyl ether, and mix them, then add distilled water to the mixture, heat and stir in a water bath at 70°C to make it gelatinized, and obtain a preliminary gelatinized product; The styrene solution is dissolved in the primary gelatinized product to obtain ...

Embodiment 2

[0038] A kind of photosensitive discoloration putty powder and preparation method thereof

[0039] Composition of color-changing putty powder:

[0040] WO 3 3kg, MoO 3 3kg, TiO 2 3kg, ZnO3kg, dithiopheneethylene 5kg, talcum powder 20kg, diatomaceous earth 30kg, glass microspheres 5kg, barite powder 5kg, SiO 2 3kg, 5kg of mica powder, 50kg of clay, 5kg of cobalt naphthoate-styrene solution with a mass concentration of 10%, 2.5kg of cyclohexanone peroxide, 2.5kg of methyl ethyl ketone peroxide, 5kg of iron red, trimethylolpropane diallyl base ether 5kg.

[0041] The preparation method is:

[0042] (1) Gelatinization: Weigh talcum powder, diatomaceous earth, glass microspheres, barite powder, SiO 2, mica powder, clay, trimethylolpropane diallyl ether, and mix them, then add distilled water to the mixture, heat and stir in a water bath at 90°C to make it gelatinized, and obtain a preliminary gelatinized product; The cobalt naphthenate-styrene solution is dissolved in the pr...

Embodiment 3

[0047] A kind of photosensitive discoloration putty powder and preparation method thereof

[0048] Composition of color-changing putty powder:

[0049] WO 3 2kg, MoO 3 2kg, TiO 2 2kg, ZnO2kg, dithiopheneethylene 3kg, talc powder 15kg, diatomaceous earth 25kg, glass microspheres 3kg, barite powder 2kg, SiO 2 2kg, 3kg of mica powder, 45kg of clay, 3kg of cobalt naphthoate-styrene solution with a mass concentration of 8%, 1.5kg of cyclohexanone peroxide, 1.5kg of methyl ethyl ketone peroxide, 3kg of chrome yellow, trimethylolpropane diallyl Base ether 3kg.

[0050] The preparation method is:

[0051] (1) Gelatinization: Weigh talcum powder, diatomaceous earth, glass microspheres, barite powder, SiO 2 , mica powder, clay, trimethylolpropane diallyl ether, and mix them, then add distilled water to the mixture, heat and stir in a water bath at 80°C to make it gelatinized, and obtain a preliminary gelatinized product; The cobalt naphthenate-styrene solution is dissolved in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com