Micro-arc oxidation method capable of controlling compositions of oxide ceramic coatings on surfaces of non-ferrous metals

A technology of surface oxide and ceramic coating, applied in the direction of anodic oxidation, etc., can solve problems such as no related reports, and achieve the effect of broad application prospects, simple use of equipment, and selective control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

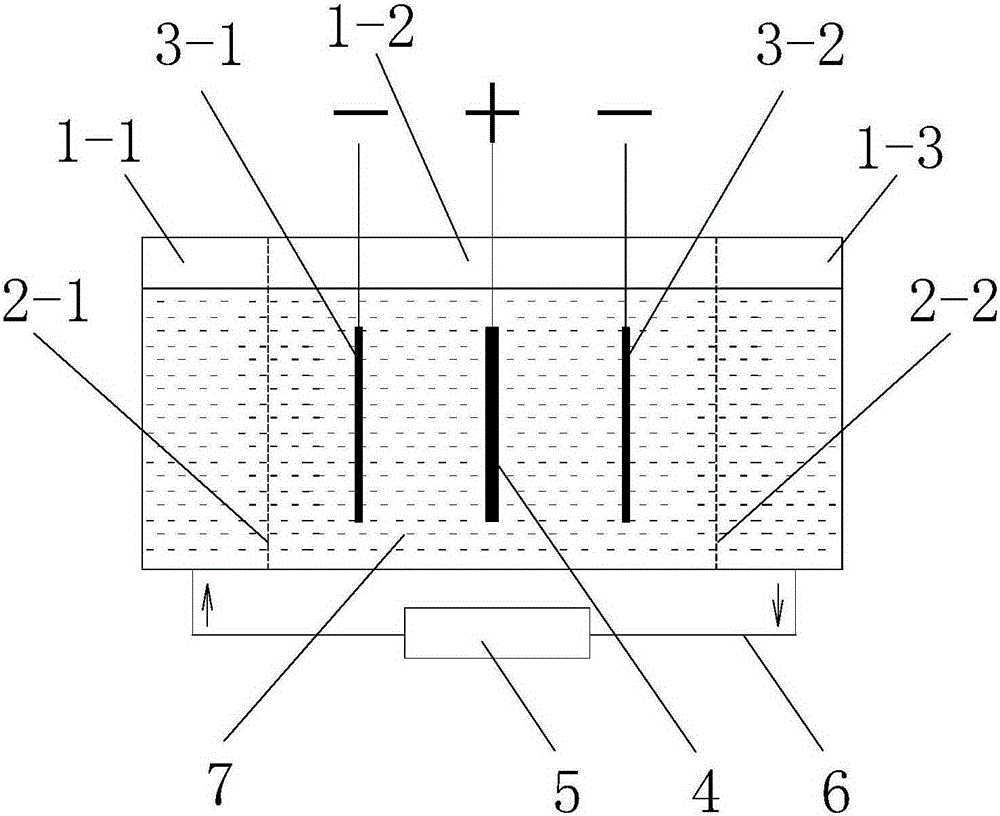

[0029] In this embodiment, a combination of reverse osmosis technology and micro-arc oxidation technology is used to prepare an oxide ceramic coating on the surface of a non-ferrous metal, and the non-ferrous metal is magnesium. combine figure 1 In this embodiment, the micro-arc oxidation method with controllable composition of the oxide ceramic coating on the surface of the non-ferrous metal comprises the following steps:

[0030] Step 1, select the first reverse osmosis membrane 2-1 and the second reverse osmosis membrane 2-2; the aperture D of the selected first reverse osmosis membrane 2-1 1 Meet: 2R x ≤D 1 ≤2.2R x , the pore diameter D of the selected second reverse osmosis membrane 2-2 2 Satisfied: D 2 x , the R x is the ionic radius of the soluble salt of the element to be deposited, R x The unit of is angstroms; in this embodiment, the element to be deposited is aluminum, and the aluminate ionic radius R x =2.5 angstroms, so the aperture of the first reverse os...

Embodiment 2

[0040] In this embodiment, a combination of reverse osmosis technology and micro-arc oxidation technology is used to prepare an oxide ceramic coating on the surface of a non-ferrous metal, and the non-ferrous metal is an aluminum alloy. combine figure 1 In this embodiment, the micro-arc oxidation method with controllable composition of the oxide ceramic coating on the surface of the non-ferrous metal comprises the following steps:

[0041] Step 1, select the first reverse osmosis membrane 2-1 and the second reverse osmosis membrane 2-2; the aperture D of the selected first reverse osmosis membrane 2-1 1 Meet: 2R x ≤D 1 ≤2.2R x , the pore diameter D of the selected second reverse osmosis membrane 2-2 2 Satisfied: D 2 x , the R x is the ionic radius of the soluble salt of the element to be deposited, R x The unit is Angstrom; in this embodiment, the element to be deposited is silicon, and the ion radius R of the silicate x =3.5 angstroms, so the aperture of the first rev...

Embodiment 3

[0051] In this embodiment, a combination of reverse osmosis technology and micro-arc oxidation technology is used to prepare an oxide ceramic coating on the surface of a non-ferrous metal, and the non-ferrous metal is a titanium alloy. combine figure 1 In this embodiment, the micro-arc oxidation method with controllable composition of the oxide ceramic coating on the surface of the non-ferrous metal comprises the following steps:

[0052] Step 1, select the first reverse osmosis membrane 2-1 and the second reverse osmosis membrane 2-2; the aperture D of the selected first reverse osmosis membrane 2-1 1 Meet: 2R x ≤D 1 ≤2.2R x , the pore diameter D of the selected second reverse osmosis membrane 2-2 2 Satisfied: D 2 x , the R x is the ionic radius of the soluble salt of the element to be deposited, R x The unit is Angstrom; in this embodiment, the element to be deposited is zirconium, and the ion radius of fluorozirconate is R x =5 angstroms, so the aperture of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com