A kind of optical device and its preparation and application

A technology for optical devices and optical products, which is applied in the field of materials and can solve problems such as expensive equipment and complex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] The present invention also provides a method for preparing the optical device, comprising the following steps:

[0093] 1) Provide the first mixed liquid, substrate and monomer A, wherein,

[0094] The first mixed solution includes monomer B, an acid-binding agent and a first solvent, and the monomer B is hexachlorocyclotriphosphazene;

[0095] The monomer A is a compound containing n functional groups selected from the following group: hydroxyl, amino, or a combination thereof, where n is 2-10;

[0096] 2) placing the substrate in the first mixed solution, and carrying out the first-stage reaction at the first temperature under agitation;

[0097] 3) Adding the monomer A to the product obtained in the previous step, continuing the second-stage reaction at a second temperature under agitation, and taking out the treated substrate to obtain the optical device.

[0098] In another preferred example, after step 3), the following steps are also included:

[0099] 4) Soxh...

Embodiment 1

[0148] Embodiment 1 Optical device 1 (using silicon wafer as substrate)

[0149] Dissolve 3ml of triethylamine and 0.2g of hexachlorocyclotriphosphazene in 50ml of anhydrous acetonitrile, add a 12×70mm single-polished silicon wafer (0.5mm in thickness) to the above solution, and stir the reaction at 40°C After 1 hour, add 0.8g of 4,4'-diaminodiphenyl ether into the above solution, continue to stir and react at 40°C for 5 hours, take out the silicon chip, and clean it by Soxhlet extraction Dry in a vacuum oven for 0.5 hour to obtain a silicon wafer on which a ring-based cross-linked polyphosphazene film 1 is deposited on the surface, that is, an optical device 1 .

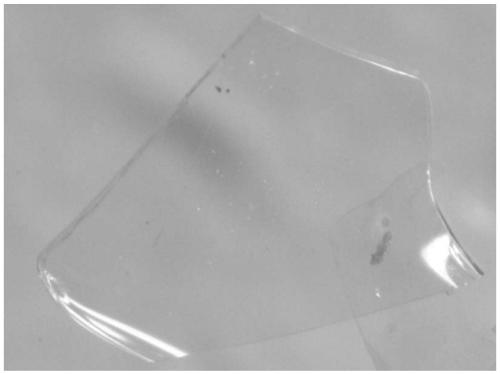

[0150] figure 1 It is an optical microscope photo of the ring-based cross-linked polyphosphazene film 1 peeled off from the silicon wafer. It can be seen that the film has good transparency. After testing, the light transmittance of the film 1 to visible light is ≥ 95%.

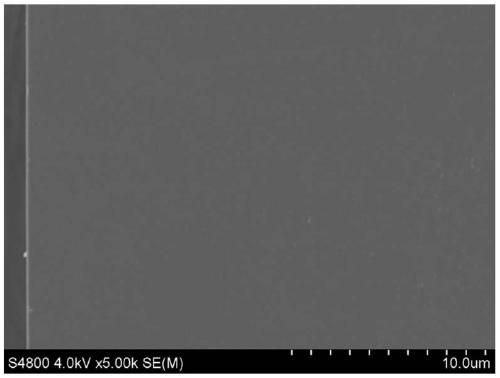

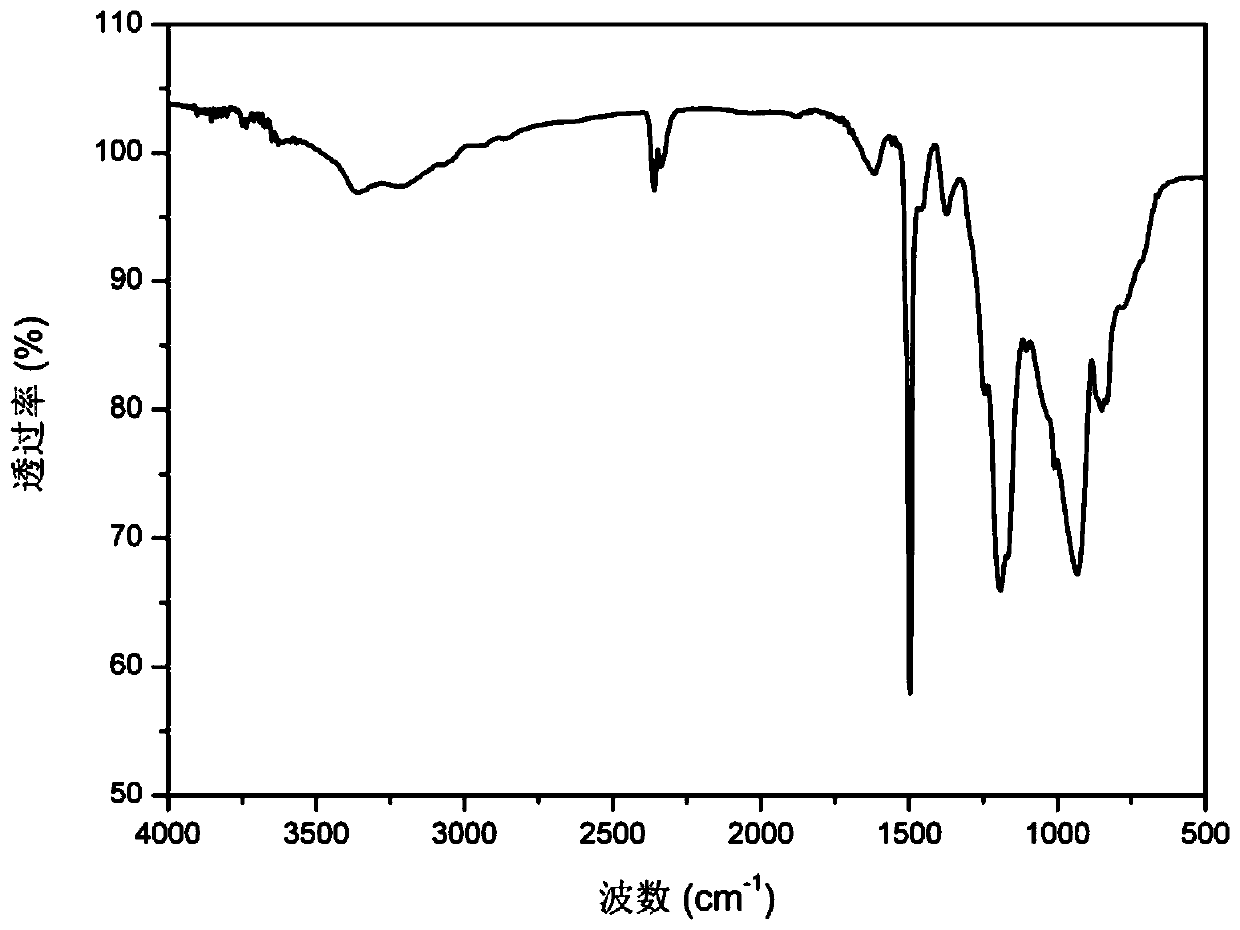

[0151] After further testing, the thicknes...

Embodiment 2

[0157] Example 2 Optics 2

[0158] With embodiment 1, difference is: prolong reaction time to 6 hours.

[0159] The performance of the polyphosphazene film 2 in the optical device 2 is basically the same as that of the polyphosphazene film 1 in the optical device 1, and the thickness of the polyphosphazene film 2 is 735nm.

[0160] Further tests show that the optical device 2 has excellent light selection and regulation performance, and the polyphosphazene film 2 of the optical device 2 can reflect orange-red light, and the reflectance measured by a reflectance spectrometer can reach 66%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com