Lithium-ion battery, used negative active material and preparation method of negative active material

A negative electrode active material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor cycle stability, large volume change, and easy pulverization of particles, and achieve high safety, high purity, Effect of reducing lattice stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

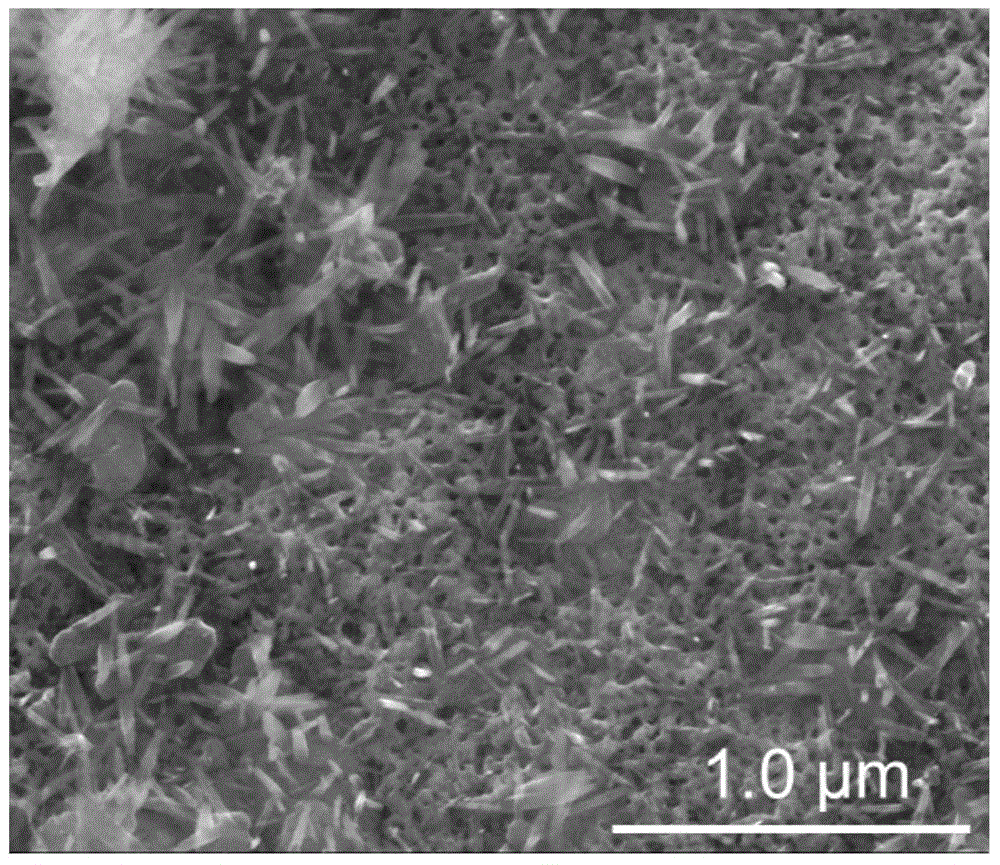

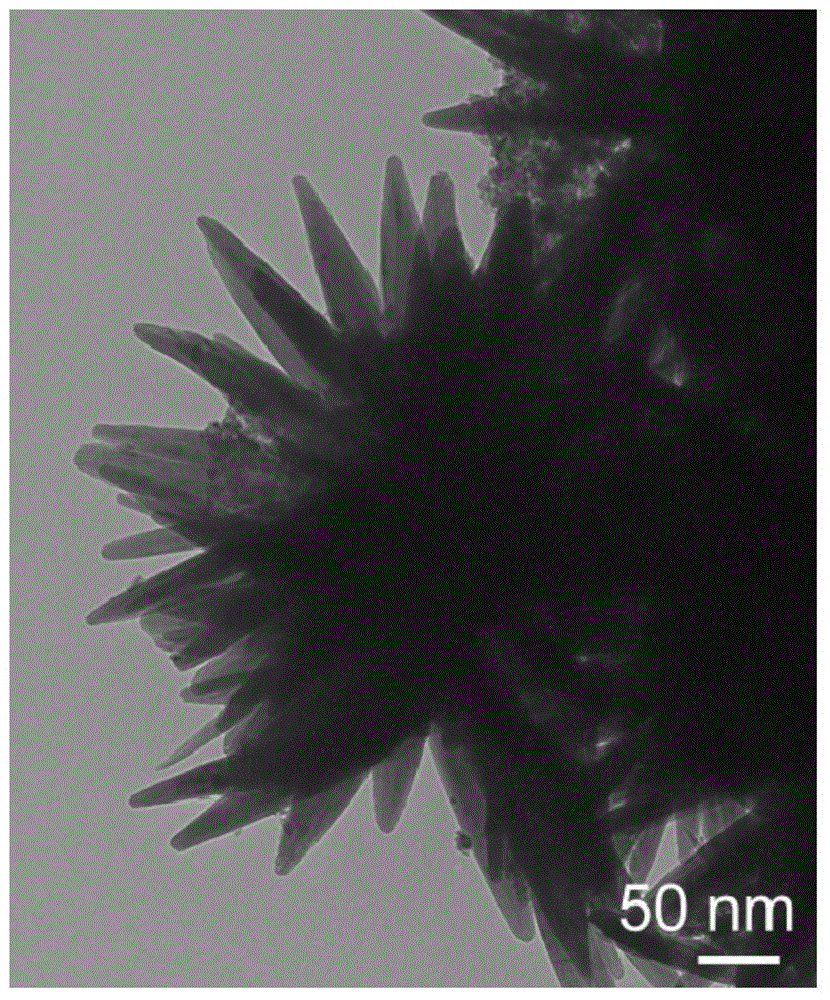

Image

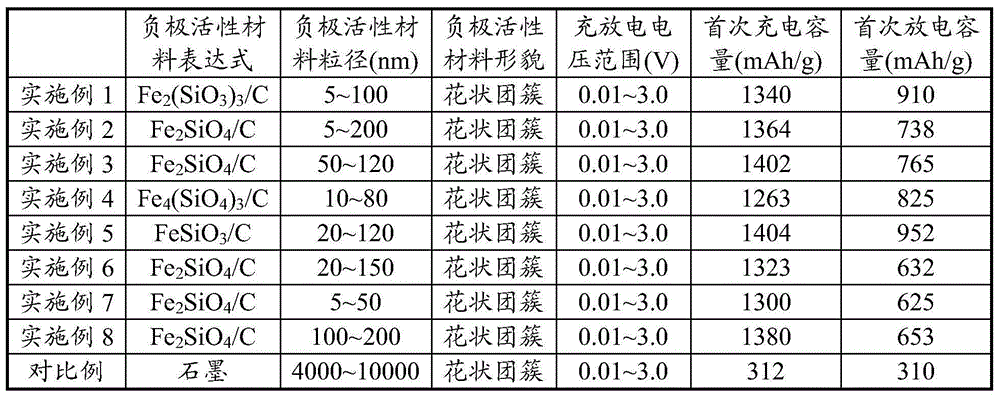

Examples

Embodiment 1

[0040] Preparation of negative electrode active materials for lithium-ion batteries:

[0041] 1) FeCl 3 Dissolve in water to obtain a reddish-brown solution with a concentration of 0.001M;

[0042] 2) Set the specific surface area to 1100m 2 g -1 The carbon black XC-72 produced by Cabot Company of the United States is ultrasonically dispersed in the solution to obtain a suspension, and the ultrasonic dispersion time is 1h. XC-72 and FeCl 3 The molar ratio is 0.18:1;

[0043] 3) Add an ethanol solution of tetraethylsilane to the suspension obtained in step 2), wherein the volume ratio of tetraethylsilane to ethanol is 1:1, tetraethylsilane and FeCl 3 The molar ratio is 1:2 / 3;

[0044] 4) With a constant stirring speed of 500 rpm and a constant temperature of 10°C, add tetrahydrofuran dropwise until the pH value of the reaction system reaches 8.0, and control the change rate of the pH value of the reaction system over time ΔpH / min to 0.01 to obtain a precipitate ;

[0045...

Embodiment 2

[0052] Preparation of negative electrode active materials for lithium-ion batteries:

[0053] 1) Fe(NO 3 ) 3 Dissolve in water to obtain a reddish-brown solution with a concentration of 0.01M;

[0054] 2) Set the specific surface area to 1500m 2 g -1 The carbon black BlackPearl2000 produced by American Cabot Company is ultrasonically dispersed in the solution to obtain a suspension, and the ultrasonic dispersion time is 1h. BlackPearl2000 and Fe(NO 3 ) 3 The molar ratio is 6.29:1;

[0055] 3) Add the ethanol solution of tetrabutyl silicate to the suspension obtained in step 2), wherein the volume ratio of tetrabutyl silicate to ethanol is 30:1, tetraethylsilane and Fe(NO 3 ) 3 The molar ratio is 1:2;

[0056] 4) Constant stirring speed is 20 rev / min, constant temperature is 20 DEG C, add ethylene oxide drop by drop until the pH value of the reaction system reaches 12.0, control the change rate of the pH value of the reaction system over time ΔpH / min is 2, get sediment...

Embodiment 3

[0061] Preparation of negative electrode active materials for lithium-ion batteries:

[0062] 1) Fe 2 (SO 4 ) 3 Dissolve in water to obtain a reddish-brown solution with a concentration of 3.0M;

[0063] 2) Ultrasonic dispersion of glucose in the solution to obtain a suspension, the ultrasonic dispersion time is 3min, glucose and Fe 2 (SO 4 ) 3 The molar ratio is 0.36:1;

[0064] 3) Add an ethanol solution of tetrapropyl silicate to the suspension obtained in step 2), wherein the volume ratio of tetrapropyl silicate to ethanol is 10:1, tetraethylsilane and Fe 2 (SO 4 ) 3 The molar ratio is 1:4 / 3;

[0065] 4) A constant stirring speed of 100 rpm, a constant temperature of 40°C, adding epichlorohydrin drop by drop until the pH value of the reaction system reaches 10.0, and controlling the change rate ΔpH / min of the pH value of the reaction system over time to 4, get sediment;

[0066] 5) After the precipitate obtained in step 4) was allowed to stand for 24 hours, it w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com