Light-beam-controllable nanowire laser based on patterning growth

A nanowire and patterning technology, applied in the field of micro-nano optics and optical nanomaterials, can solve the problems of low utilization rate of light energy, scattering of emitted light emitted by nanowires, difficulty in controlling the direction of emitted light, etc., and achieves simple structure and tunable Large-scale, high-reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

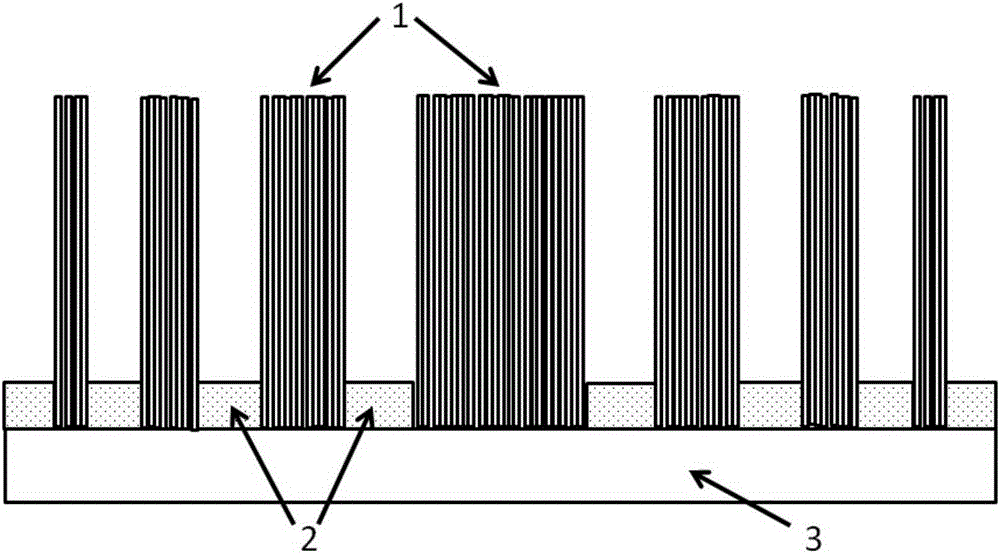

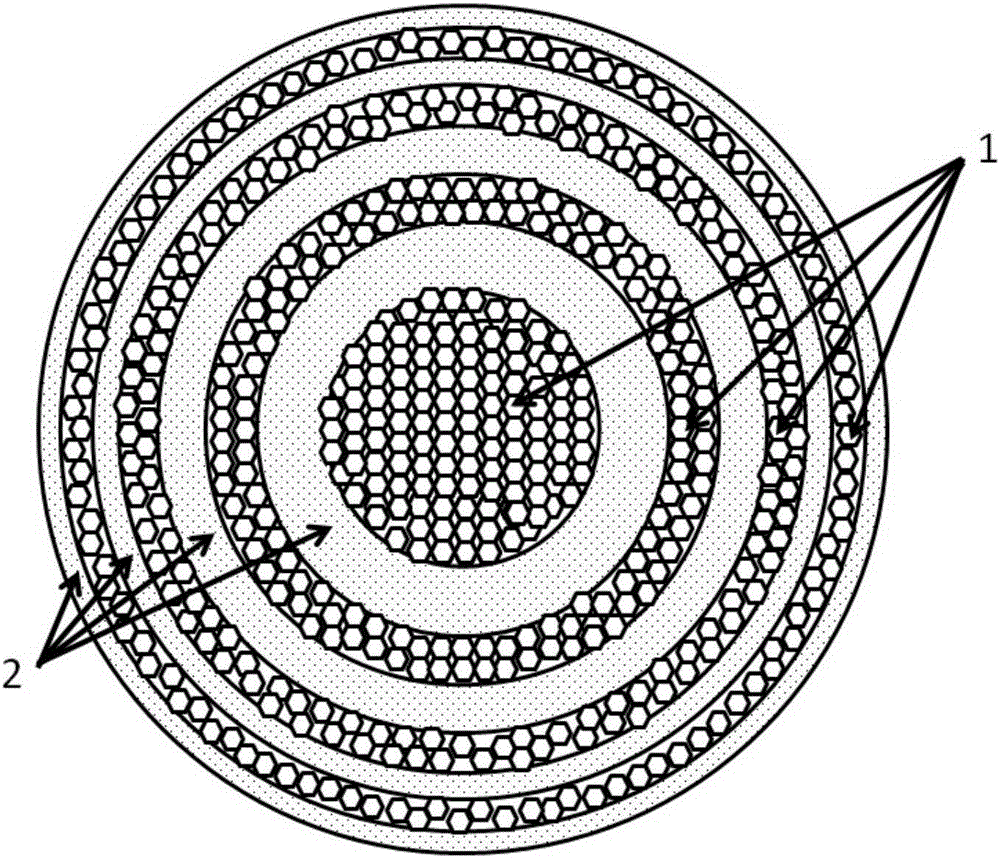

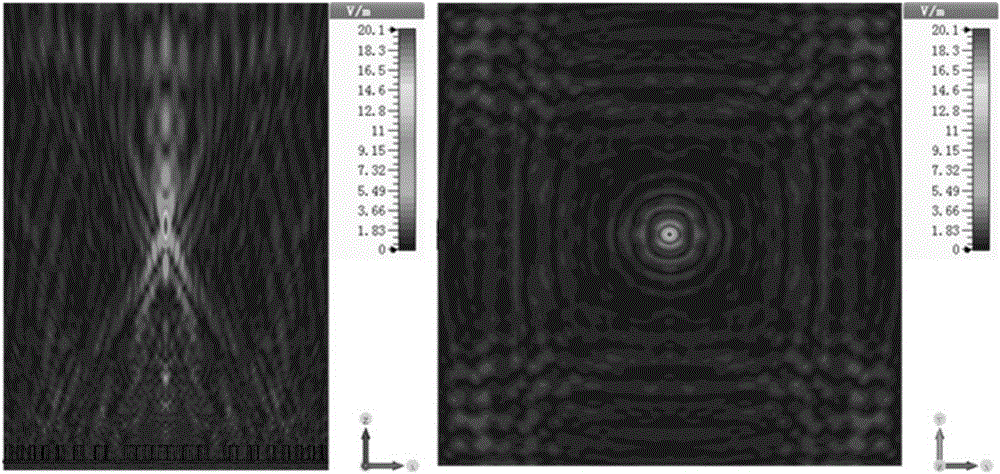

[0019] Embodiment 1: In this embodiment, zinc oxide nanowires with a diameter of 200nm are taken as an example. The material of the isolation medium 2 is silicon dioxide with a refractive index of 1.47 and a thickness of 100nm; the pattern is etched on the isolation medium by photolithography , the graphic area is a Fresnel focusing lens model composed of eight concentric rings, and the radii of each ring are 4.43 μm; 6.85 μm; 8.6 μm; 10.05 μm; 11.31 μm; 12.45 μm; 13.73 μm; The design focal length is 35 μm. The material of the semiconductor nanowire 1 is zinc oxide, the refractive index is 2.45, the diameter is 200 nm, and the length is 5 μm. The nanowires grow within the grooves of the patterned isolation dielectric. The unit Fresnel lens nanolaser has a diameter of 14.75 μm. The material of the substrate 3 is gallium nitride, and the volume is (length×width×height) 50 μm×50 μm×100 μm. In this embodiment, a glass cover is used for sealing; in this embodiment, the volume of...

Embodiment 2

[0021] Embodiment 2: In this embodiment, a zinc oxide nanowire with a diameter of 100 nm is taken as an example, the length of the nanowire 4 is 1 μm, and the designed focal length of the nanowire laser is 20 μm, and the rest are the same as in Embodiment 1. In this embodiment, due to the short design focal length, the nanowires are thinner and denser. After calculation, the actual focal length of the nanowire laser is 19 μm, and the light intensity at the focus center is 480 times that of the incident light intensity, which corresponds to a higher light intensity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com