A kind of synthetic method of epoxy-terminated butanol polyoxyethylene polyoxypropylene ether

A technology of polyoxyethylene polyoxypropylene ether and synthesis method, which is applied in the field of organic compound synthesis, can solve problems such as limited catalyst cycle life, catalyst failure to recycle, catalyst equipment corrosion, etc., and achieve high selectivity and good industrial application value , less side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

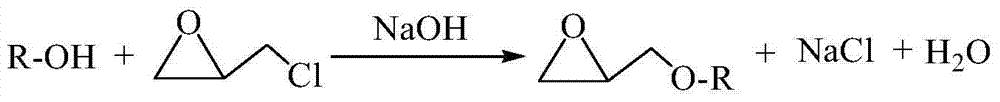

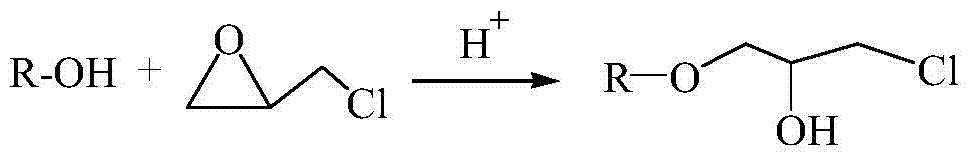

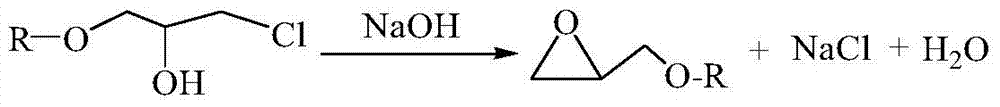

Method used

Image

Examples

Embodiment 1

[0050] Dissolve 1.6g of ammonium metatungstate in 6.5ml of deionized water, add to 12.6g of Zr(OH) 4 immersion at 80-90°C for 24 hours, then dried at 110°C, and calcined at 700°C for 3 hours in an air atmosphere to obtain a catalyst with a tungsten content of 10wt%.

Embodiment 2

[0052] Dissolve 0.75g of ammonium metatungstate in 6.5ml of deionized water, add to 12.6g of Zr(OH) 4 immersion at 80-90°C for 24 hours, then dried at 110°C, and calcined at 700°C for 3 hours in an air atmosphere to obtain a catalyst with a tungsten content of 5wt%.

Embodiment 3

[0054] Dissolve 2.6g of ammonium metatungstate in 6.5ml of deionized water, add to 12.6g of Zr(OH) 4 immersion at 80-90°C for 24 hours, then dried at 110°C, and calcined at 700°C for 3 hours in an air atmosphere to obtain a catalyst with a tungsten content of 15wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

| color | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com