Halogen-free flame-retardant composite material and preparation method thereof

A flame retardant composite material and flame retardant technology, applied in the field of composite materials, can solve the problems of deteriorating the mechanical properties of composite materials, reducing the flame retardant effect, poor processing performance, etc., achieving good coordination of the flame retardant effect and improving the flame retardant performance. , The effect of improving impact resistance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

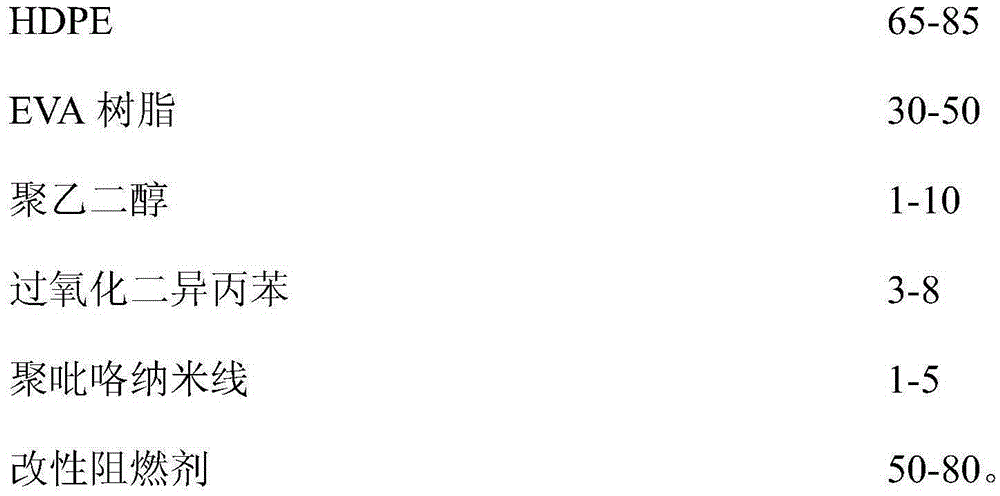

[0046] A halogen-free flame-retardant composite material, the halogen-free flame-retardant composite material is mainly prepared from the following raw materials in parts by weight:

[0047]

[0048] Preparation:

[0049] (1) Grind the raw materials of the formulated amount to 500 mesh, then place them in a mixer and mix them evenly, and then dry them at 95°C for 5 hours;

[0050] (2) The dried raw materials are granulated through a twin-screw extruder. The temperature of the solid delivery zone of the twin-screw extruder is 320° C., the temperature of the plasticizing zone of the material is 180-860° C., and the temperature of the melt delivery zone is The temperature is 320-420°C; an antistatic HDPE composite material is obtained.

Embodiment 2

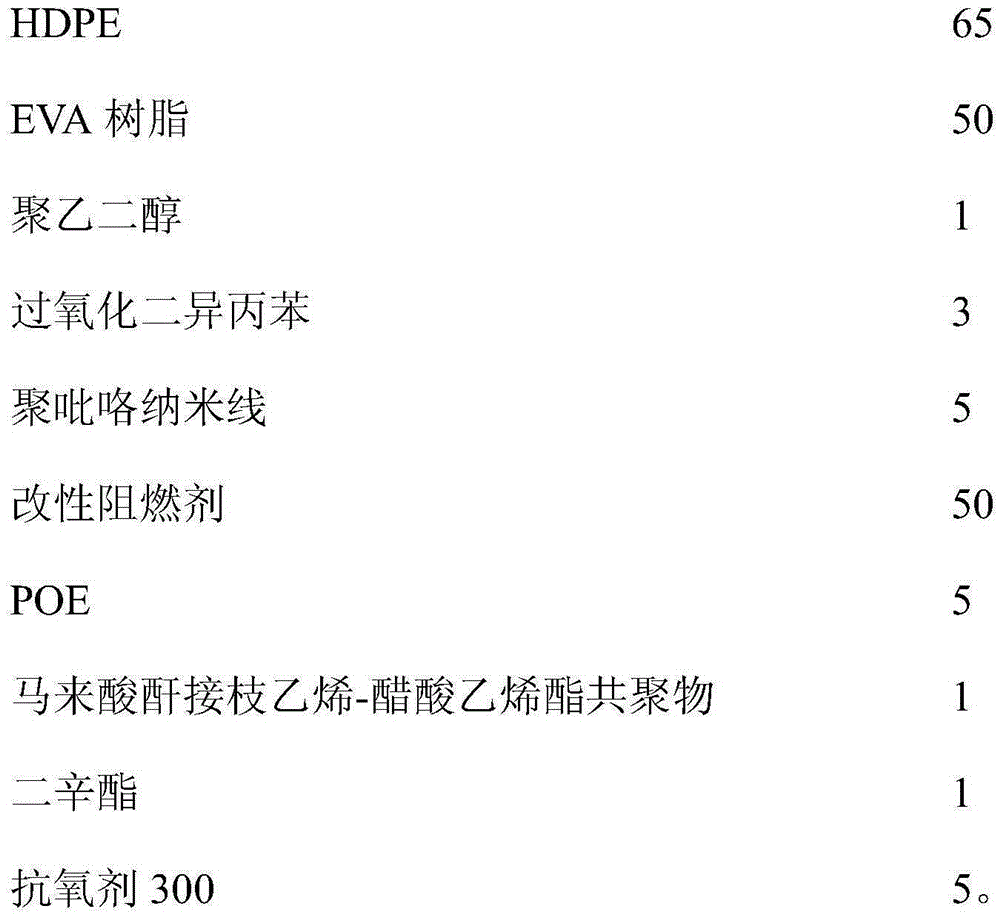

[0052] A halogen-free flame-retardant composite material, the halogen-free flame-retardant composite material is mainly prepared from the following raw materials in parts by weight:

[0053]

[0054] The preparation method is the same as in Example 1.

Embodiment 3

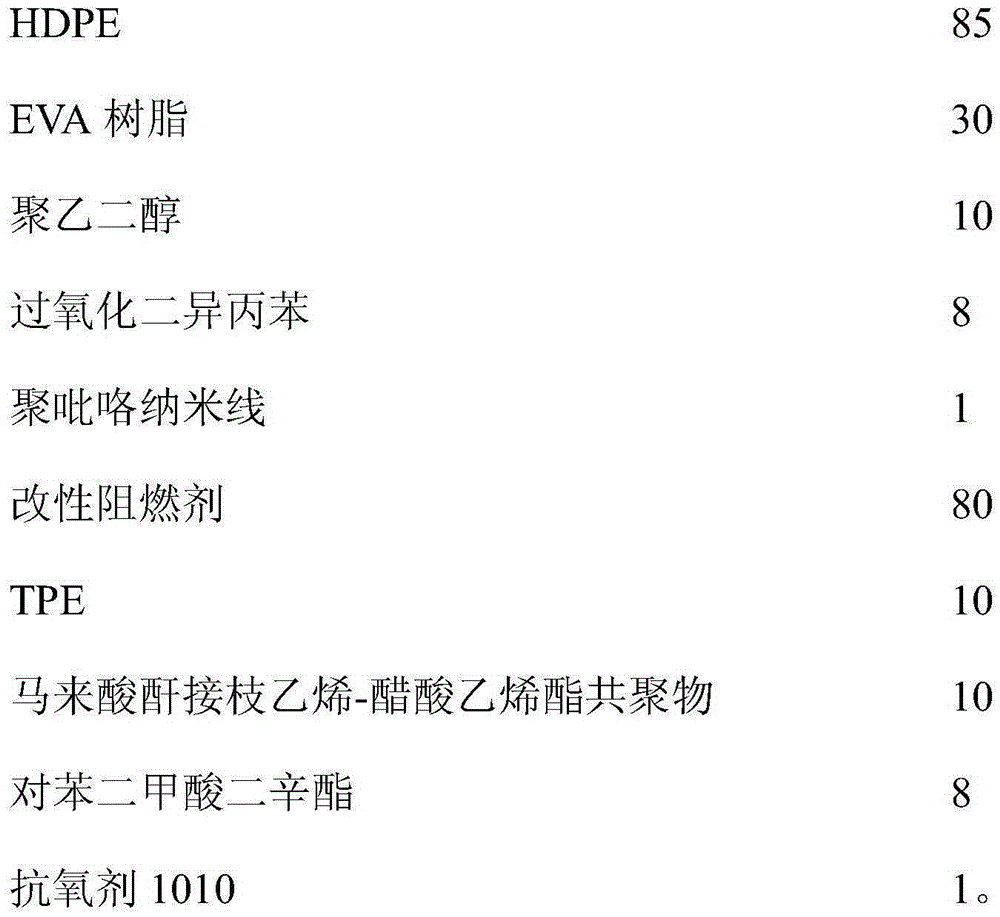

[0056] A halogen-free flame-retardant composite material, the halogen-free flame-retardant composite material is mainly prepared from the following raw materials in parts by weight:

[0057]

[0058]

[0059] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com