Internal paint

A technology of painting and parts by weight, which is applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as waste of resources, pollution of the environment, health hazards of construction workers, etc., and achieve reduction of environmental pollution and low VOC content , Excellent anti-corrosion performance

Inactive Publication Date: 2016-02-17

TIANJIN MEISHIBANG PAINT CHEM IND

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Traditional food container paints are mostly solvent-based paints. During the production and application process, a large amount of toluene, xylene and other organic solvents that are harmful to the human body are added, and these solvents are volatilized into the atmosphere, which not only causes waste of resources At the same time, it will cause harm to the health of construction workers and seriously pollute the environment.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

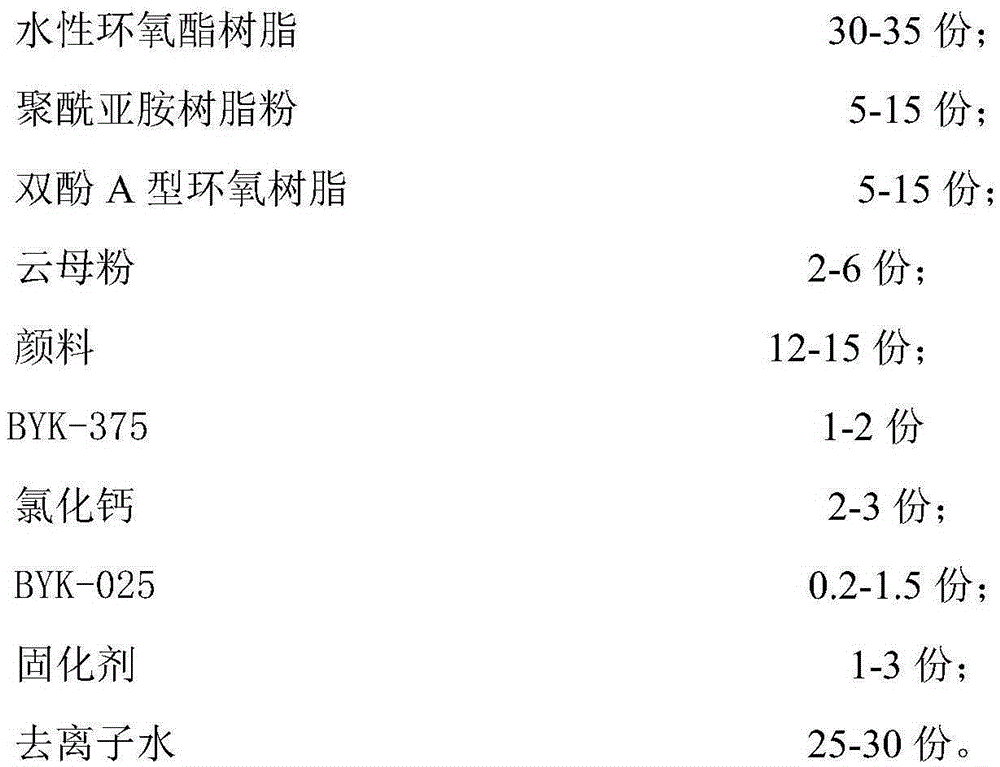

[0013] A kind of container paint, is prepared from by comprising the raw material of following parts by weight:

[0014]

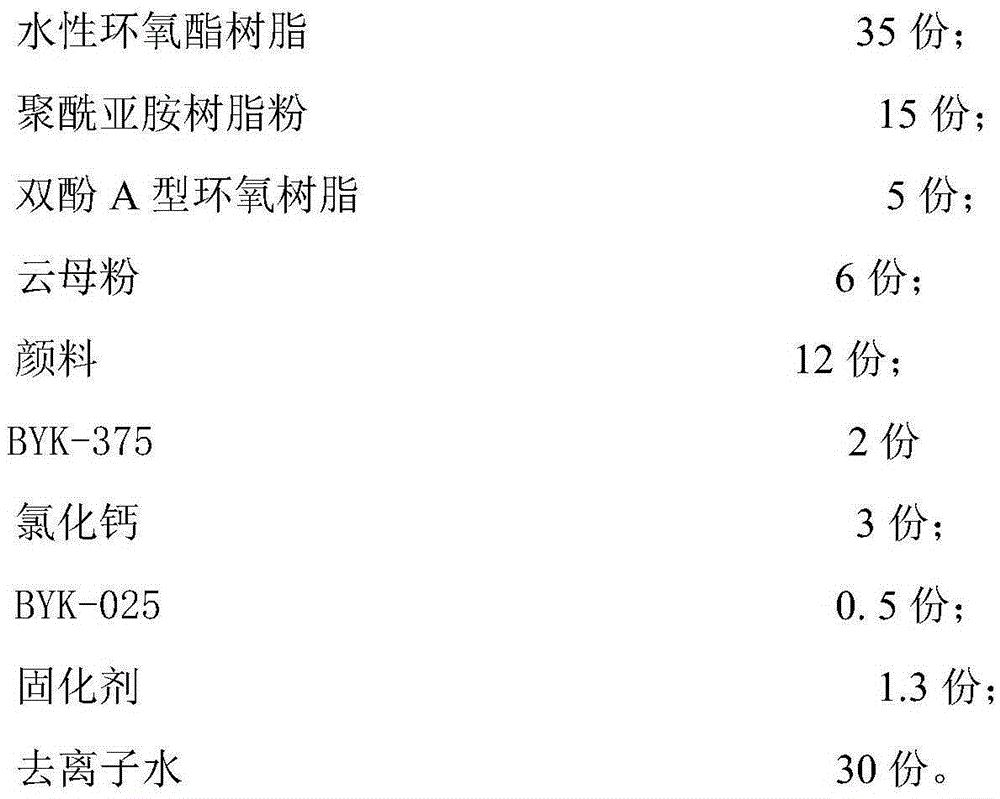

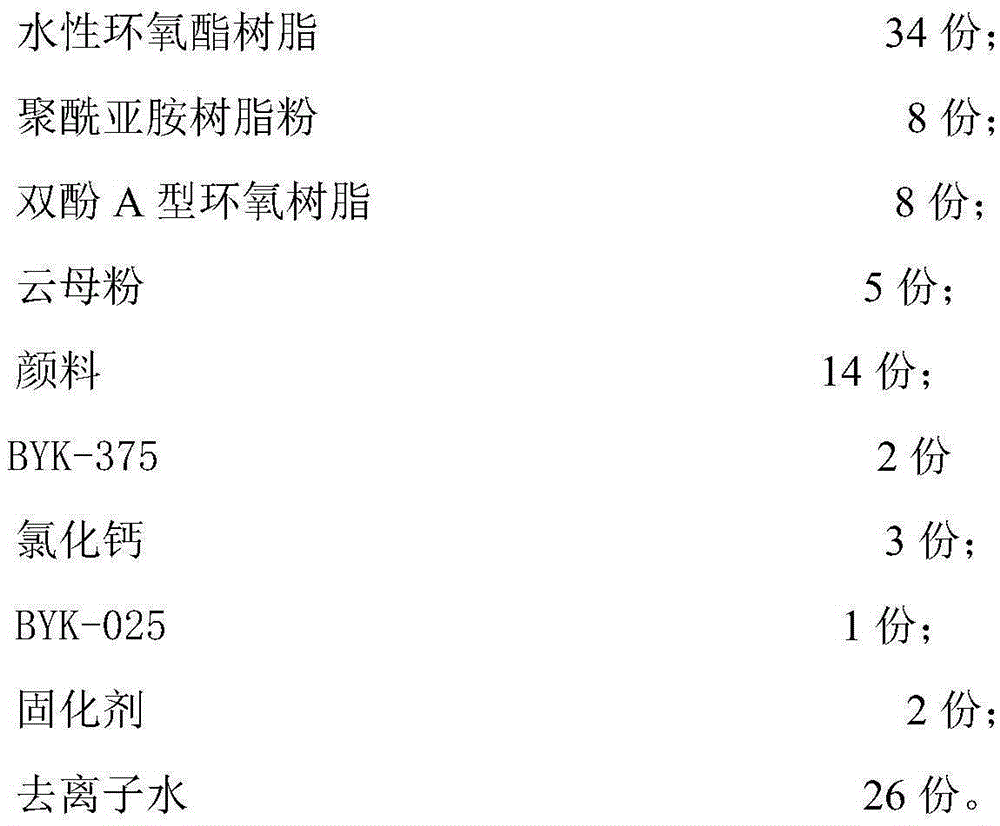

Embodiment 2

[0016] A kind of container paint, is prepared from by comprising the raw material of following parts by weight:

[0017]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to internal paint. The internal paint is prepared from raw materials in parts by weight as follows: 30-35 parts of water-based epoxy ester resin, 5-15 parts of polyimide resin powder, 5-15 parts of bisphenol-A epoxy resin, 2-6 parts of mica powder, 12-15 parts of a pigment, 1-2 parts of BYK-375, 2-3 parts of calcium chloride, 0.2-1.5 parts of BYK-025, 1-3 parts of a curing agent and 25-30 parts of deionized water. With the adoption of the internal paint for containers, coatings can resist the temperature from subzero 20 DEG C to 50 DEG C and has good oil resistance, water resistance, good adhesion, good toughness and excellent corrosion resistance and the low content of VOCs (volatile organic compounds).

Description

technical field [0001] The invention relates to a paint, in particular to a container interior paint. Background technique [0002] Traditional food container paints are mostly solvent-based paints. During the production and application process, a large amount of toluene, xylene and other organic solvents that are harmful to the human body are added, and these solvents are volatilized into the atmosphere, which not only causes waste of resources At the same time, it will cause harm to the health of construction workers and seriously pollute the environment. With the improvement of people's awareness of the environment and the increasingly stringent requirements for environmental protection, it is an inevitable development direction to develop environmentally friendly coatings with low VOC or even zero VOC. [0003] Coatings for the interior of food containers should be tough enough to withstand deformation during container preparation without damage to the coating during tr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D163/00C09D179/08C09D5/08C09D7/12C09D7/00

CPCC09D163/00C08L2205/025C08L2205/03C09D7/20C09D7/61

Inventor 于涛

Owner TIANJIN MEISHIBANG PAINT CHEM IND

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com