Method for extracting soluble dietary fibers from rice bran through extruding-expansion assisted with enzymolysis

A technology of extrusion puffing and assisted enzymatic hydrolysis, which is applied in the fields of food extraction, food science, food hydrolysis, etc., can solve the problems of inconvenient production and extraction, high cost and high cost, and achieve comprehensive utilization, wide application range and practicality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

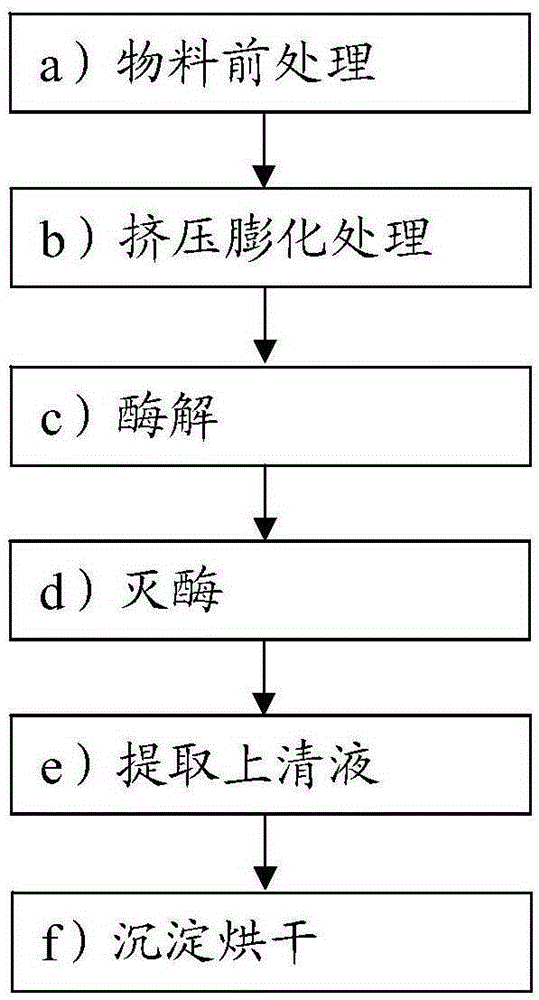

Image

Examples

Embodiment 1

[0039] a) Material pretreatment: select fresh rice bran, grind the rice bran and pass through a 40-mesh sieve;

[0040] b) Extrusion and expansion treatment: the crushed rice bran is extruded and expanded by a twin-screw extruder, and the extruded and expanded rice bran is cooled to room temperature before being further pulverized. The water content is 10%, the extrusion temperature is 110°C, and the screw speed is 150r / min;

[0041] c) Enzymolysis: add the rice bran after pressurized puffing treatment and further pulverization into boiling water, the weight volume ratio of rice bran to boiling water is 1:50, stir evenly, after cooling to room temperature, add 1.0% α- Amylase, carry out enzymolysis reaction at 70°C and pH 6.0 for 30 minutes;

[0042] d) Enzyme inactivation: Enzyme inactivation is carried out on the rice bran after enzymolysis, and then cooled to room temperature. The enzyme inactivation condition is heating at 105° C. for 10 minutes;

[0043] e) extracting t...

Embodiment 2

[0047] a) Material pretreatment: select fresh rice bran, grind the rice bran and pass through a 40-mesh sieve;

[0048] b) Extrusion and expansion treatment: the crushed rice bran is extruded and expanded by a twin-screw extruder, and the extruded and expanded rice bran is cooled to room temperature before being further pulverized. Moisture content 30%, extrusion temperature 150°C, screw speed 250r / min;

[0049] c) Enzymolysis: add extruded and expanded rice bran into boiling water, the weight-to-volume ratio of rice bran to boiling water is 1:50, stir evenly, and after cooling to room temperature, add 2.5% α- Amylase, carry out the enzymolysis reaction at 90°C and pH 8.0 for 150 minutes;

[0050] d) Enzyme inactivation: Enzyme inactivation is carried out on the rice bran after enzymolysis, and then cooled to room temperature. The enzyme inactivation condition is heating at 100° C. for 15 minutes;

[0051] e) Extract the supernatant: add 55ml of NaOH solution with a mass vol...

Embodiment 3

[0055] a) Material pretreatment: select fresh rice bran, grind the rice bran and pass through a 40-mesh sieve;

[0056] b) Extrusion and expansion treatment: the crushed rice bran is extruded and expanded by using a twin-screw extruder, and after the extruded and expanded rice bran is cooled to room temperature, it is further pulverized. The water content is 10%, the extrusion temperature is 110°C, and the screw speed is 150r / min;

[0057] c) Enzymolysis: add the rice bran after pressurized puffing treatment and further crushing into boiling water, the weight-to-volume ratio of rice bran to boiling water is 1:50, stir evenly, and after cooling to room temperature, add 2.0% α- Amylase, carry out the enzymolysis reaction at 75°C and pH 6.0 for 90 minutes;

[0058] d) Enzyme inactivation: Enzyme inactivation is carried out on the rice bran after enzymolysis, and then cooled to room temperature. The enzyme inactivation condition is heating at 105° C. for 10 minutes;

[0059] e) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com