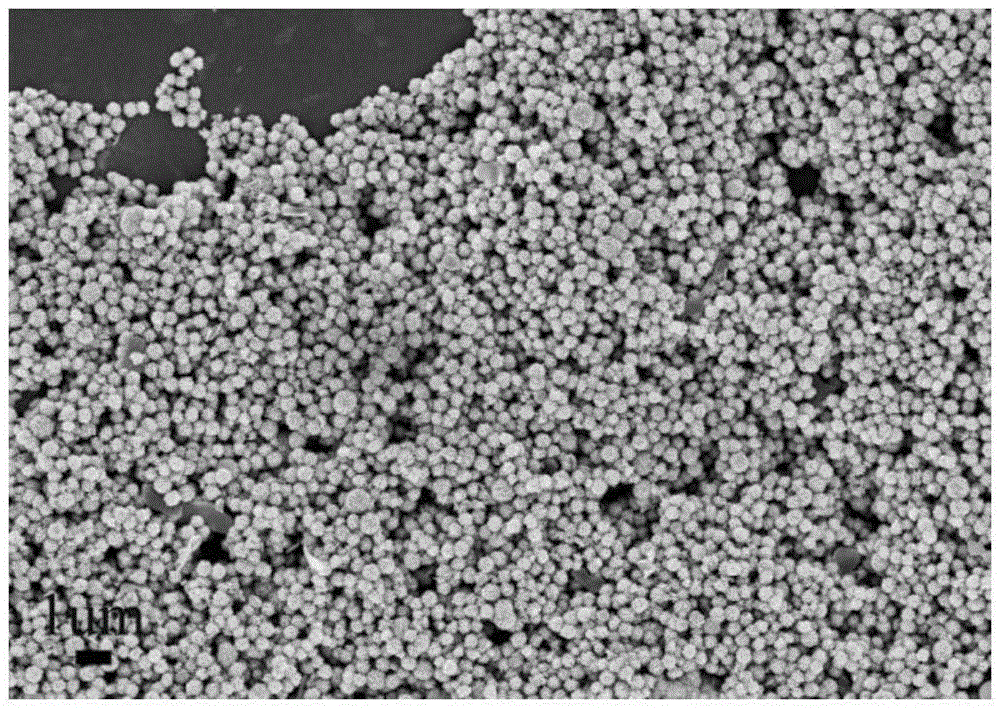

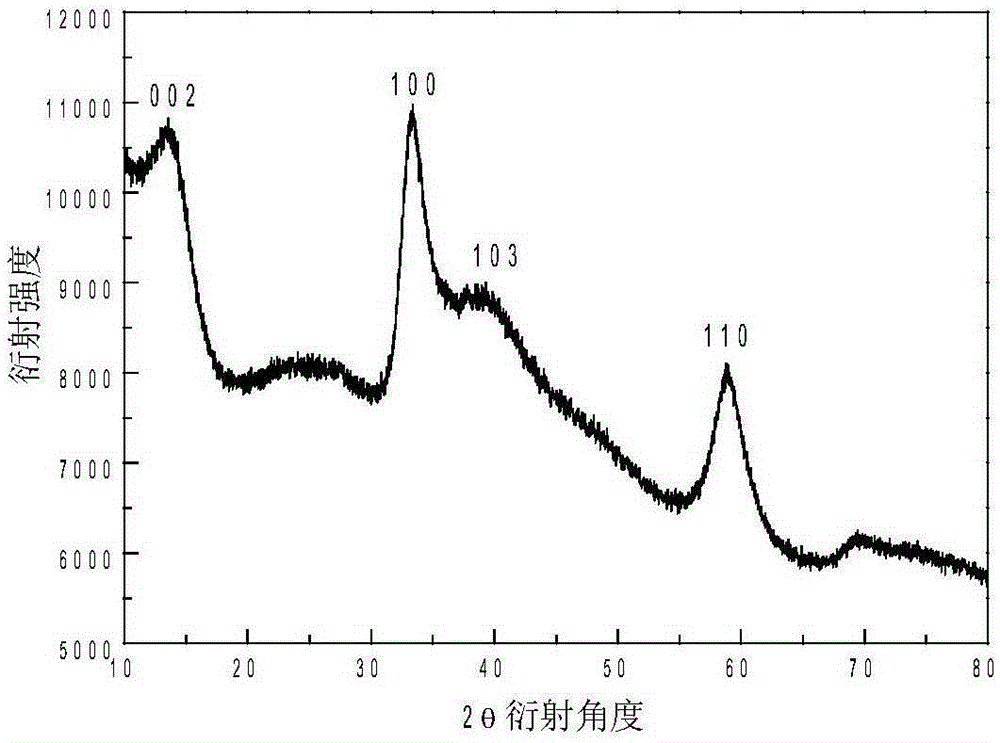

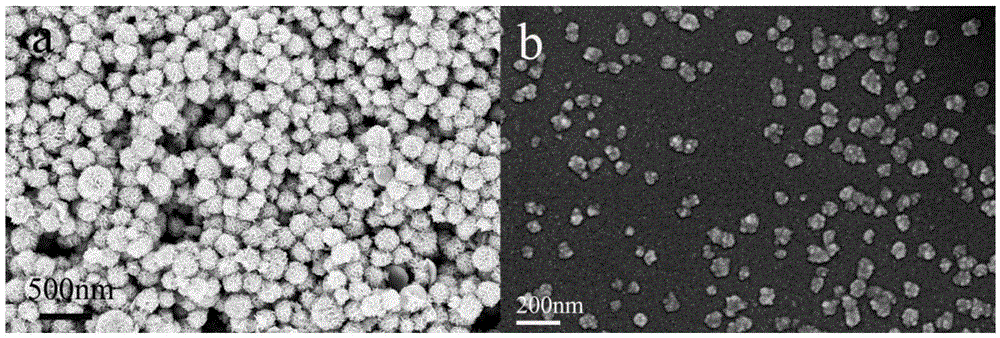

Method used for controllable preparation of monodisperse mesoporous molybdenum disulfide nanospheres

A technology of molybdenum disulfide and nanospheres, applied in the direction of molybdenum sulfide, nanotechnology, nanotechnology, etc., can solve the problems of not reaching the nanometer level, uneven size of nanospheres, and inability to control the size and surface pore size of nanospheres at the same time. Achieve the effect of low cost, stable mechanical strength and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Dissolve 0.1g of ammonium thiomolybdate solid (that is, 10 parts of Mo salt solution) in 10ml of water, add 12.5ml of benzene (that is, add 5 parts of organic solvent), and 10g of surfactant (that is, 10 parts of surfactant), and prepare The solution was mixed, heated and stirred, and refluxed, the temperature was controlled at 80° C., and the reaction time was 3 hours. Weigh SiO 2 Sol 10ml, the mass fraction is 5% (that is, 10 parts of SiO 2 Sol), pour into the mixed solution, and stir for 30min. Put the mixture into a stainless steel reaction kettle, 180 o C response 3days. The solid in the kettle was taken out, washed with 10% HF solution, and centrifuged to obtain mesoporous MoS 2 nanospheres.

Embodiment 2

[0036]Dissolve 0.5g of ammonium thiomolybdate solid (50 parts of Mo salt solution) in 10ml of water, add 162.5ml of benzene (that is, add 65 parts of organic solvent), 0.5g of surfactant (that is, add 0.5 parts of surfactant), Make a mixed solution, heat and stir, reflux, the temperature is controlled at 90°C, and the reaction time is 5h. Weigh SiO 2 Sol 5ml, the mass fraction is 5% (that is, 5 parts of SiO 2 Sol), pour into the mixed solution, and stir for 30min. Put the mixture into a stainless steel reaction kettle, 260 o C response 3days. The solid in the kettle was taken out, washed with 40% HF solution, and centrifuged to obtain mesoporous MoS 2 nanospheres.

Embodiment 3

[0038] Dissolve 1.2g of ammonium thiomolybdate solid in 10ml of water, add 110ml of benzene and 2g of surfactant to make a mixed solution, heat and stir, reflux, the temperature is controlled at 100°C, and the reaction time is 8h. Weigh SiO 2 Sol 20ml, mass fraction 8%, poured into the mixed solution, stirred for 1h. Put the mixture into a stainless steel reaction kettle, 200 o C response 3days. The solid in the kettle was taken out, washed with 15% HF solution, and centrifuged to obtain mesoporous MoS 2 nanospheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com