Preparation method for series of polyurethane catalysts

A technology of polyurethane catalyst and solid acid catalyst, which is applied in the field of preparation of a series of polyurethane catalysts, can solve problems such as inability to prepare THBA, and achieve the effects of low equipment operation requirements, easy handling, and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Mode 1, the preparation method of a silicon-aluminum supported solid acid catalyst with a silicon-aluminum ratio of 1:1, using SiO 2 / Al 2 o 3 =The mass ratio of 1:1 is carrier, carries out following steps successively:

[0053] (1) Dipping:

[0054] Immerse 50g of the carrier in 150ml of ammonium sulfate aqueous solution with a mass concentration of 25%, filter after 25 hours, and dry at 65-75°C to constant weight;

[0055] Repeat the above-mentioned soaking, filtering and drying twice more to obtain the precipitate I;

[0056] (2) Roasting:

[0057] Calcining the precipitate I at 400-420° C. for 3 hours to obtain a silica-alumina supported solid acid catalyst.

Embodiment 1

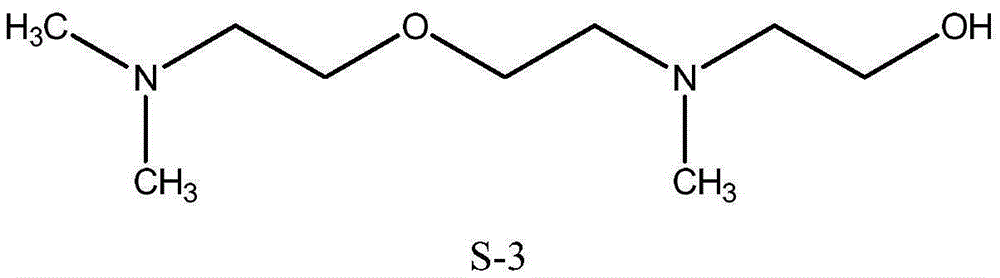

[0058] Example 1, a silicon-aluminum supported solid acid catalyst with a silicon-aluminum ratio of 1:1 (prepared in the above method 1), using N,N-dimethylethanolamine and N-methyldiethanolamine as starting materials, Follow the steps in order:

[0059] 1) synthesis

[0060] Add 356g (4mol) N,N-dimethylethanolamine, 476g (4mol) N-methyldiethanolamine, 40g silica-alumina supported solid acid catalyst into a 1000ml stainless steel autoclave, and replace the air in the autoclave with nitrogen for 2 minutes. Lower the temperature to 145-155°C and react for 15 hours. After the reaction time is up, stop heating, cool down to 30°C, vent, filter, and take the filtrate for rectification in the following steps. The filter cake is used as a silica-alumina supported solid acid catalyst for the next batch of reactions.

[0061] 2) Distillation and separation

[0062] The filtrate is transferred to a 1000ml single-necked flask equipped with a 30cm packed rectification column (using Rasc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com