Octenyl succinic anhydride modified starch prepared through dry mechanical force induction of esterification reaction and application thereof

A technology of octenyl succinic acid and octenyl succinic anhydride, which is applied in the fields of application, edible oil/fat, and edible oil/fat components, and can solve problems such as excessive reaction, uneven reaction, and long reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 The method for preparing octenyl succinic acid starch ester based on dry mechanical force induced esterification of ball milling is exemplified

[0030] 1. Raw materials and equipment: The test material is commercially available glutinous rice starch (food grade), the chemical reagents are analytically pure, purchased from a chemical reagent company, and the ball mill model is MITR-QM-QX-40L.

[0031] 2. Esterification process

[0032] (1) Mixing: take 30kg of glutinous rice starch, and spray 0.8% (accounting for starch dry base) concentration 4% NaOH solution and 4% (accounting for starch dry base) octenyl succinic anhydride in the glutinous rice starch evenly Mixed solution, stir and mix, add 120kg glutinous rice starch again, mix, the mixed material that obtains;

[0033] (2) Grinding: take ball milling beads (wherein the weight ratio of balls with a diameter of 6 mm and a diameter of 3 mm is 7:3) 100 g, put into the ball mill tank of the ball mill togethe...

Embodiment 2

[0034] Example 2 Example of the method for preparing octenyl succinic acid starch ester by dry mechanical force-induced esterification based on Raymond mill

[0035]1. Raw materials and equipment: The test material is commercially available glutinous rice starch (food grade), and the chemical reagents are all analytically pure, purchased from a chemical reagent company, and the Raymond mill model is CXLM-4R.

[0036] 2. Raymond mill esterification process

[0037] (1) material mixing: with the esterification process step (1) in embodiment 1;

[0038] (2) Grinding: Turn on the milling machine and electromagnetic vibrating feeder, adjust the speed of the main machine to 140r / min, at this time, the centrifugal force F on the grinding roller is about 3433N, the reaction temperature is 45°C, and the grinding time is 0.5h to obtain micronization Esterified starch, the measured degree of substitution is 0.0212, and the reaction efficiency is 81.58%. Calculated as follows:

[0039]...

Embodiment 3

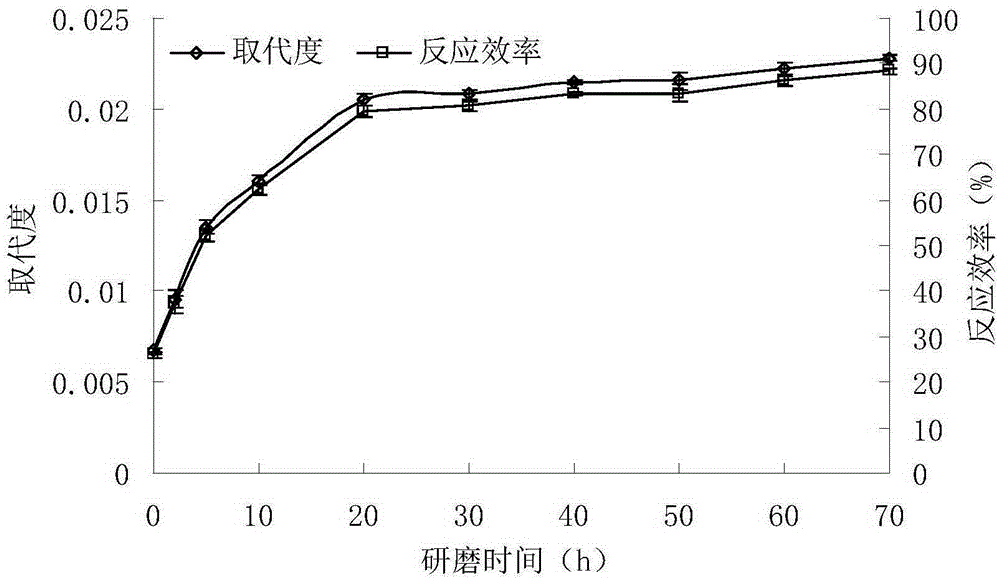

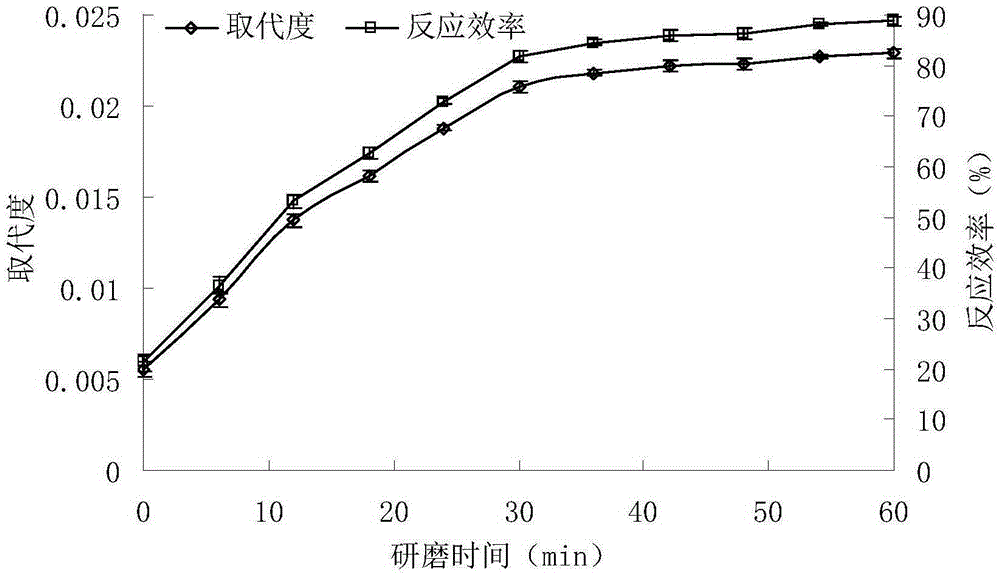

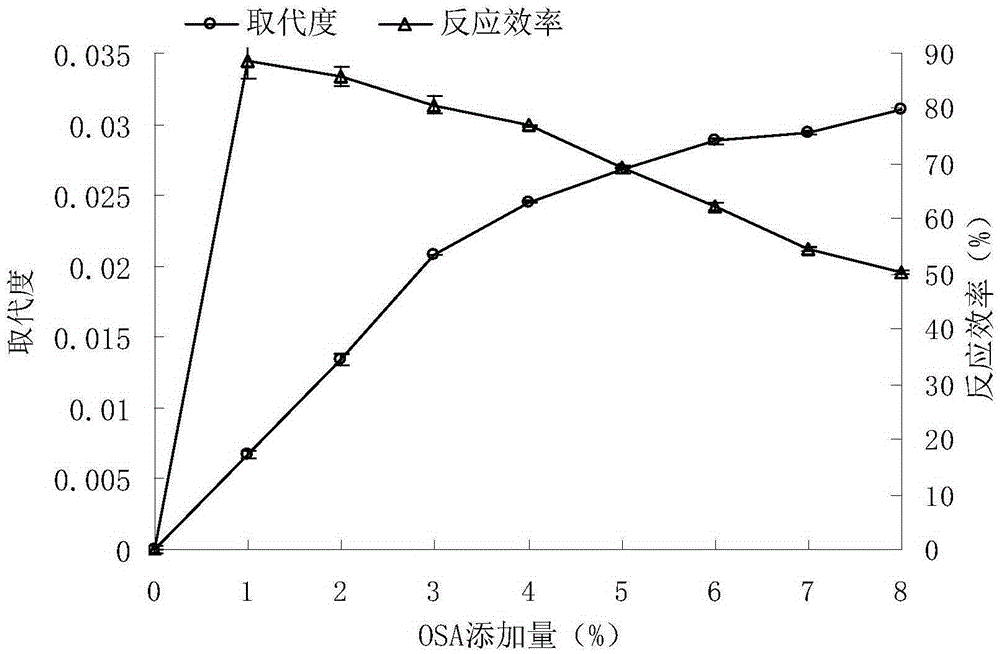

[0041] Example 3 The impact of grinding time on the degree of substitution and reaction efficiency of octenyl succinic acid starch ester

[0042] According to the steps of Example 1 or 2, the starch octenyl succinate was prepared by ball milling or Raymond milling respectively. The effect of milling time on degree of substitution (DS) and reaction efficiency (RE) of starch octenyl succinate was studied. The determination of substitution degree and reaction efficiency refers to the method of reference (Heetal., 2006). Calculated as follows:

[0043] D S = 0.162 * ( V * M ) / W 1 - [ 0.210 * ( V * M ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com