Plastic filling master batch and preparation method thereof

A technology for filling master batches and plastics, applied in the field of plastic filling master batches and their preparation, can solve the problems of difficulty in powder cleaning and conversion, large energy waste, and high manufacturing costs, and achieves less energy consumption, short operating procedures, and less dust. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

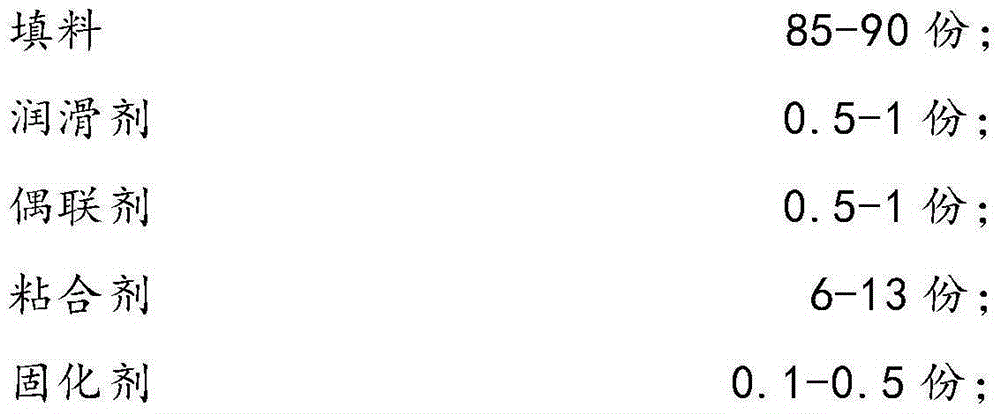

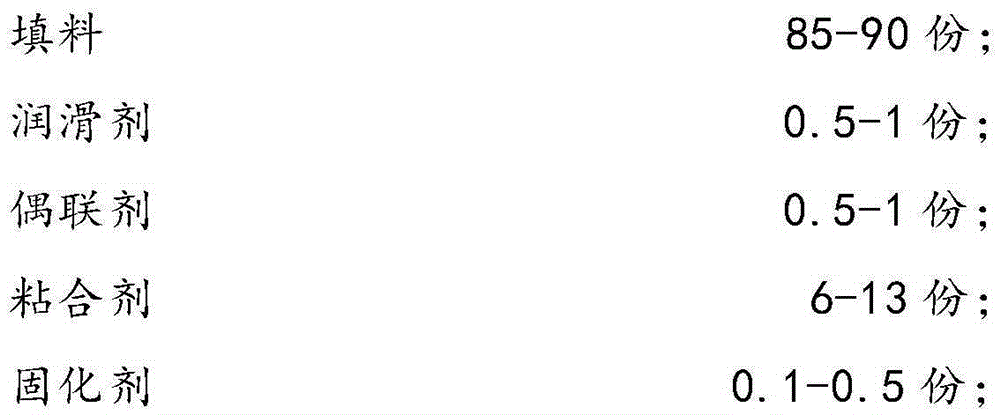

Method used

Image

Examples

Embodiment 1

[0030] Take 90 parts of 3000 mesh calcium carbonate, 1 part of zinc stearate, 1 part of aminosilane coupling agent, put them into the mixer and mix for 1-5min, the speed is 1000rpm, and the surface temperature of the mixture is controlled at 40-50℃; Change, add 7.8 parts of liquid bisphenol A epoxy resin, continue mixing for 10-20min, control the temperature at 50-60℃; put 0.2 parts of maleic anhydride into the mixture and continue stirring for 5-15min, the temperature rises to 70- At 80°C, the masterbatch particles are basically formed, and the diameter of the obtained masterbatch is 0.1-1.0mm, which is spherical. At this point, the material can be discharged and cooled to obtain the finished masterbatch.

Embodiment 2

[0032] Take 85 parts of 1250 mesh talc powder, 1 part of zinc stearate, and 1 part of epoxy silane coupling agent, put them into the mixer and mix for 1-5min, the speed is 1000rpm, and the surface temperature of the mixture is controlled at 40-50℃; Keep it unchanged, add 12.8 parts of liquid bisphenol A epoxy resin, continue mixing for 10-20min, control the temperature at 50-60℃; put 0.2 parts of phthalic anhydride into the mixture and continue stirring for 5-15min, the temperature When the temperature rises to 70-80°C, the masterbatch particles are basically formed, and the diameter of the obtained masterbatch is 0.1-0.3mm, which is spherical. At this point, the material can be discharged and cooled to obtain the finished masterbatch.

Embodiment 3

[0034] Take 88 parts of 3000 mesh barium sulfate, 1 part of zinc stearate, and 1 part of titanate coupling agent, put them into the mixer and mix for 1-5 minutes, the speed is 1000 rpm, and the surface temperature of the mixture is controlled at 40-50 °C; No change, add 9.8 parts of liquid bisphenol A epoxy resin, continue mixing for 10-20min, control the temperature at 50-60℃; put 0.2 parts of methyl hexahydrophthalic anhydride into the mixture and continue stirring for 5-15min, the temperature rises At 70-80°C, the masterbatch particles are basically formed, and the diameter of the obtained masterbatch is 0.1-0.5mm, which is spherical. At this point, the material can be discharged and cooled to obtain the finished masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com