Metallic surface anti-corrosion paint and preparing method thereof

An anti-corrosion coating and metal technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of coating blistering, lack of stimuli-responsive release of corrosion inhibitors, and inability to play a protective role. Achieve the effect of high yield, superior coating function and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

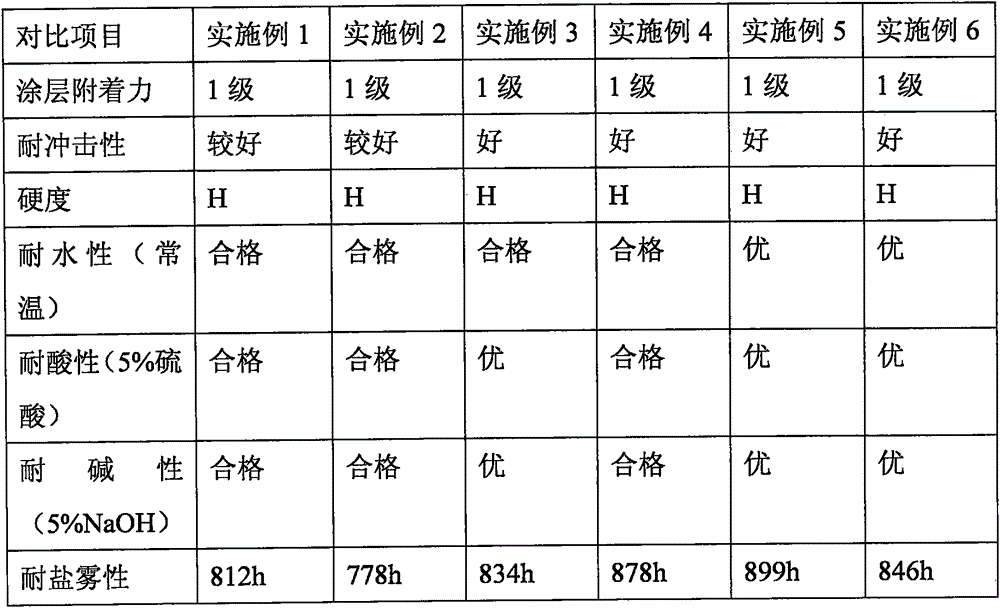

Embodiment 1

[0023] The metal anti-corrosion coating is made of the following raw materials according to the weight ratio: 60 parts of epoxy acrylic resin, 10 parts of butylated amino resin, 5 parts of fluorocarbon resin, 2 parts of methyl isobutyl ketone, and 2 parts of cobalt oxide , 1 part of zinc phosphate, 1 part of aluminum tripolyphosphate, 5 parts of polymer nanoparticles coated with benzotriazole, 2 parts of polyacrylate, 1 part of xylene, 2 parts of triethylenetetramine and industrial water 40 servings.

Embodiment 2

[0025] The metal anti-corrosion coating is made of the following raw materials according to the weight ratio: 70 parts of epoxy acrylic resin, 15 parts of butylated amino resin, 8 parts of fluorocarbon resin, 5 parts of methyl isobutyl ketone, and 4 parts of cobalt oxide , 2 parts of zinc phosphate, 1 part of aluminum tripolyphosphate, 8 parts of polymer nanoparticles coated with benzotriazole, 4 parts of polyacrylate, 2 parts of xylene, 3 parts of triethylenetetramine and industrial water 50 servings.

Embodiment 3

[0027] The metal anti-corrosion coating is made of the following raw materials according to the weight ratio: 70 parts of epoxy acrylic resin, 15 parts of butylated amino resin, 8 parts of fluorocarbon resin, 5 parts of methyl isobutyl ketone, and 4 parts of cobalt oxide , 2 parts of zinc phosphate, 1 part of aluminum tripolyphosphate, 9 parts of polymer nanoparticles coated with benzotriazole, 4 parts of polyacrylate, 2 parts of xylene, 4 parts of triethylenetetramine and industrial water 50 servings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com