Preparation method of fluorine-containing polyacrylic copolymer antibacterial composite material, obtained product and application thereof

A kind of copolymer, polyacrylic acid technology, applied in the fields of botanical equipment and methods, chemicals for biological control, applications, etc., can solve the problem of low surface energy of fluoropolymers, difficult to interact with substrates, and inability to obtain coatings, etc. To reduce the spread and infection of bacteria, prevent the reduction of sterilization efficiency, and achieve the effect of high sample yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

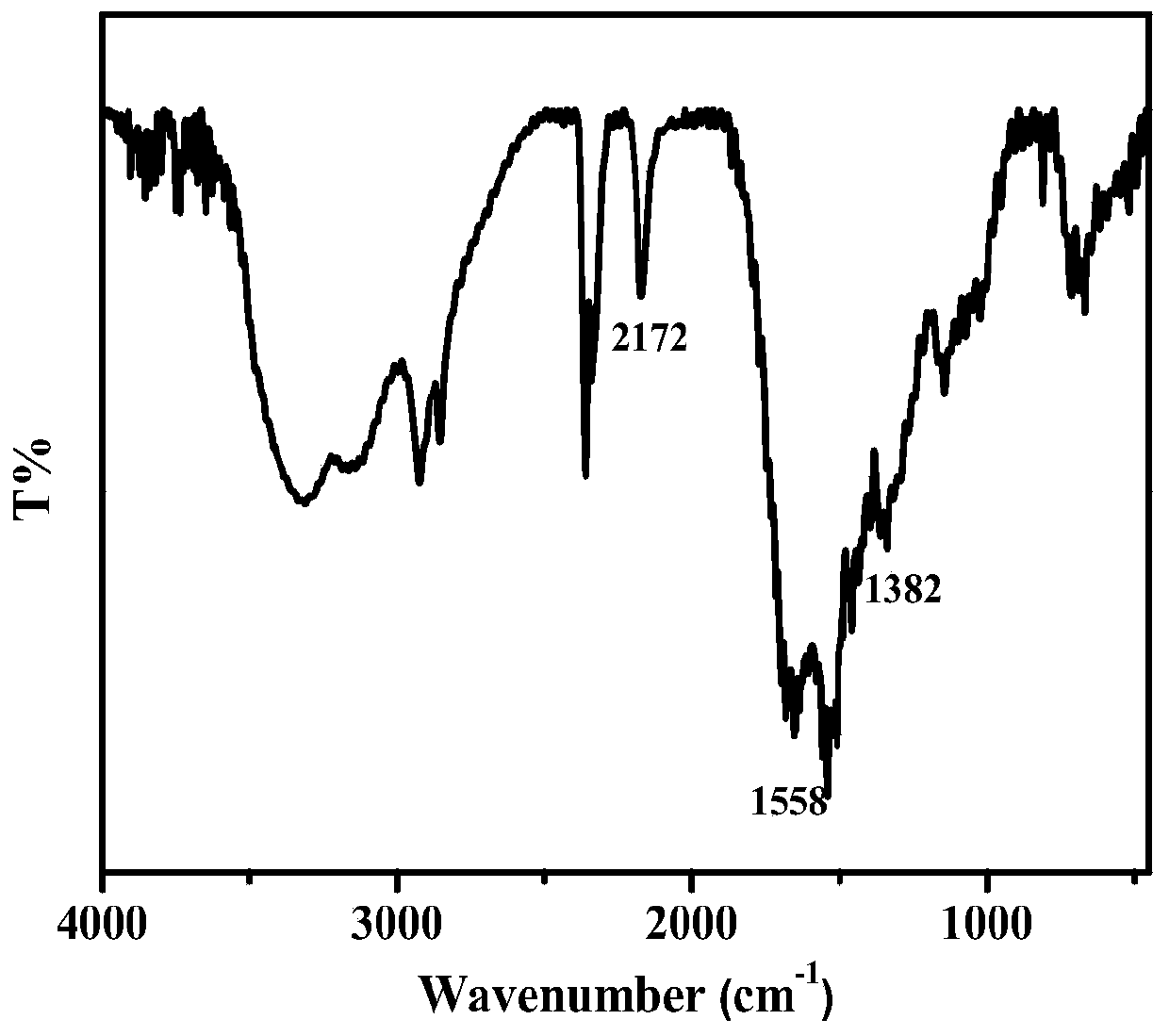

[0051] (1) Synthesis of fluorine-containing polyacrylic acid copolymer

[0052] Monomer acrylic acid and 1H,1H,2H,2H - ethyl perfluorodecyl acrylate and azobisisobutyronitrile are dissolved with THF, the solid content of the resulting solution is 10wt%, and the solution is dissolved in N 2 Under protection, the temperature was raised to 65°C, and the temperature was kept for 8 hours. The obtained precipitate was washed three times with n-hexane, and dried for later use.

[0053] (2) Fluorine-containing polyacrylic acid copolymer cross-linked in water

[0054] Dissolve fluorine-containing polyacrylic acid copolymer in ultrapure water to prepare a solution with a concentration of 25wt%, add an aziridine crosslinking agent with a carboxyl molar mass of 5% to the solution, stir at room temperature for 1 hour, and place the solution in dialysis Dialyze the bag to remove excess crosslinker.

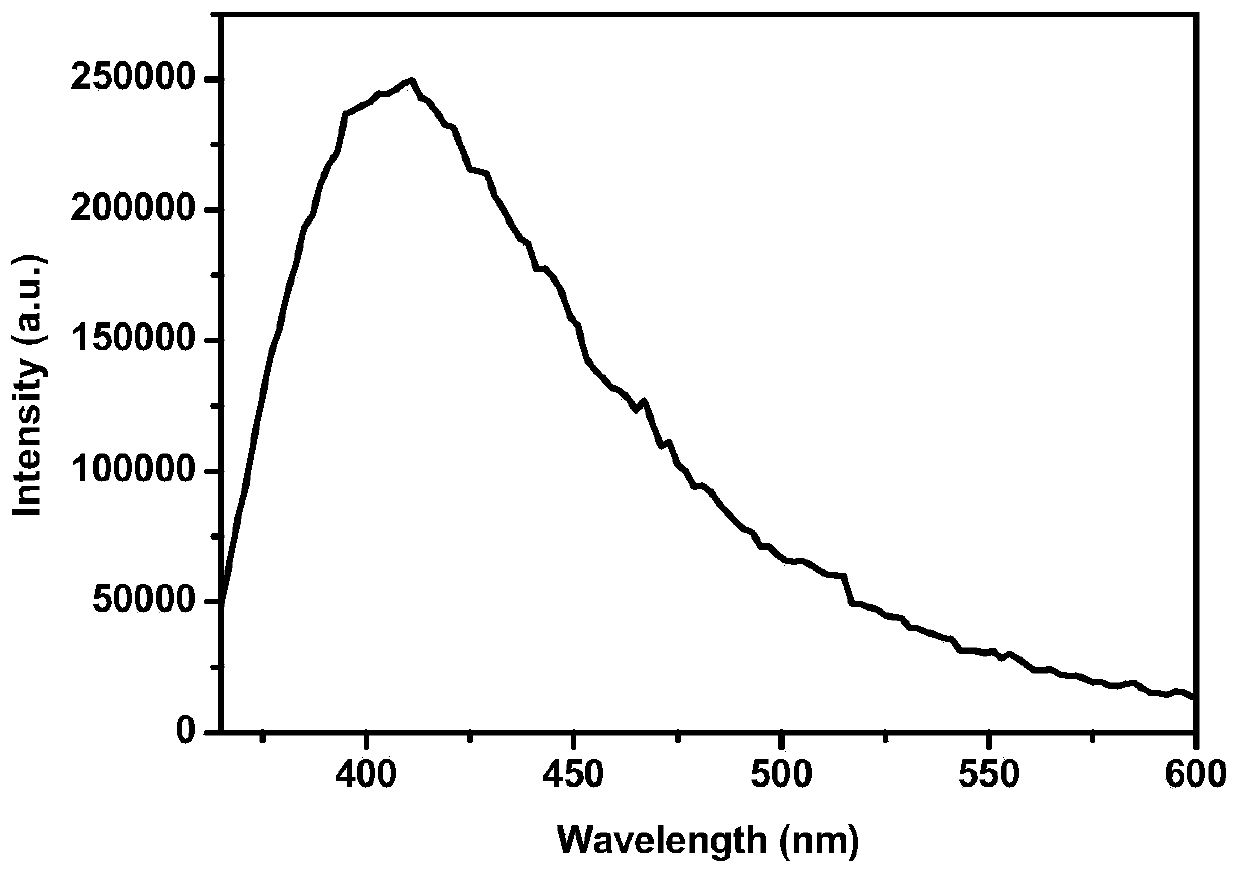

[0055] (3) Slightly cross-linked fluorine-containing polyacrylic acid copolymer compoun...

Embodiment 2

[0060] Prepare fluorine-containing polyacrylic acid copolymer antibacterial composite material according to the method of Example 1, the difference is: in step (1), it is prepared by RAFT polymerization, and the specific experimental steps are: acrylic acid and 1H,1H,2H,2H -perfluorodecyl ethyl acrylate, azobisisobutyronitrile and trithioester are dissolved in THF, the solid content of the solution is 10wt%, and the solution is dissolved in N 2 Under protection, the temperature was raised to 65°C, and the temperature was kept for 24 hours. The obtained precipitate was washed three times with n-hexane, and dried for later use. According to the plate test, no live bacteria were detected on the surface of the film, indicating that the film has good anti-bacterial adhesion and bactericidal effects. The antibacterial composite material has no cytotoxicity as detected by the cytotoxicity test.

Embodiment 3

[0062] Prepare fluorine-containing polyacrylic acid copolymer antibacterial composite material according to the method of Example 1, the difference is: in step (1), the used 1H,1H,2H,2H - Ethyl perfluorodecyl acrylate is replaced by perfluorooctylethyl methacrylate, the molar ratio of acrylic acid to perfluorooctylethyl methacrylate is 50:1. After the plate test, the anti-adhesion test film surface detected 10CFU / cm 2 Live bacteria, no live bacteria were detected on the surface of the film in the bactericidal experiment, indicating that the film has good anti-bacterial adhesion and bactericidal effects. The antibacterial composite material has no cytotoxicity as detected by the cytotoxicity test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com