Structure of micro device of microfluidic chip series

A technology for microfluidic chips and microdevices, applied in fluid controllers, instruments, laboratory utensils, etc., can solve the problems of glass chip development limitations, inability to manufacture pump valve systems, and unsatisfactory cost and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

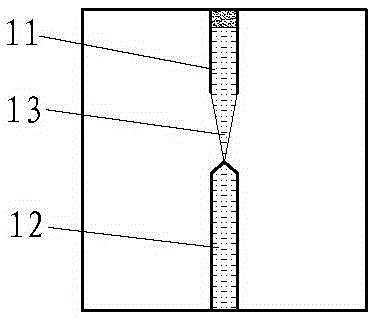

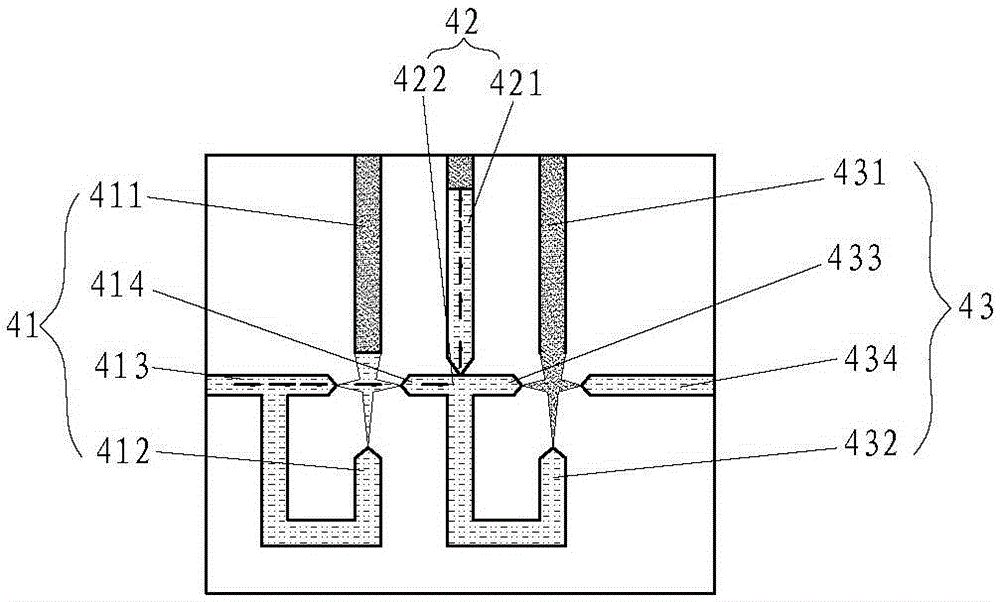

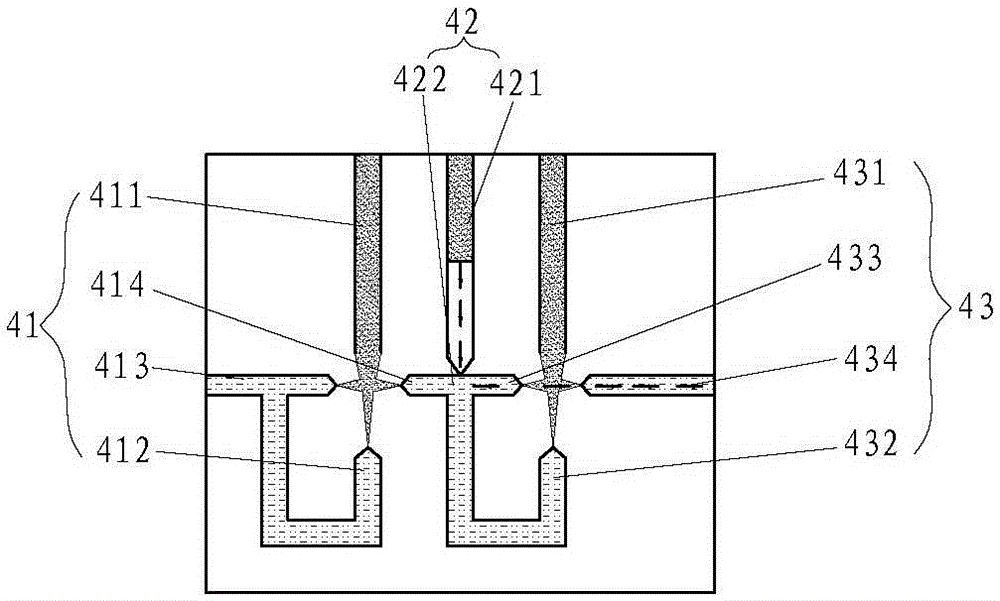

[0028] The present invention discloses a microfluidic chip series microdevice. In terms of structural design, the series microdevice includes a gas channel and at least one liquid channel, and the gas channel and each liquid channel are communicated through microchannels (capillary tubes).

[0029] The theoretical basis of the present invention is: there is a definite relationship between the pressure difference of the gas-liquid interface in the gas-liquid two-phase and the moving direction of the gas-liquid interface in the microchannel, and the purpose of two aspects can be achieved by using this relationship: A gas -The movement of the liquid interface can reflect the pressure difference between the gas-liquid two phases; B controls the movement of the gas-liquid interface by controlling the pressure difference between the gas-liquid two phases.

[0030] The following will be described with specific examples.

[0031] See Figure 1a to Figure 1c is a schematic diagram of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com