Analysis method of chromium in chromium vanadium hydrogen storage alloy

A hydrogen storage alloy and analysis method technology, applied in the field of analytical chemistry, can solve the problems of increased workload and analysis cost, large interference in measurement, large workload, etc., and achieve the effects of easy grasp, elimination of interference, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

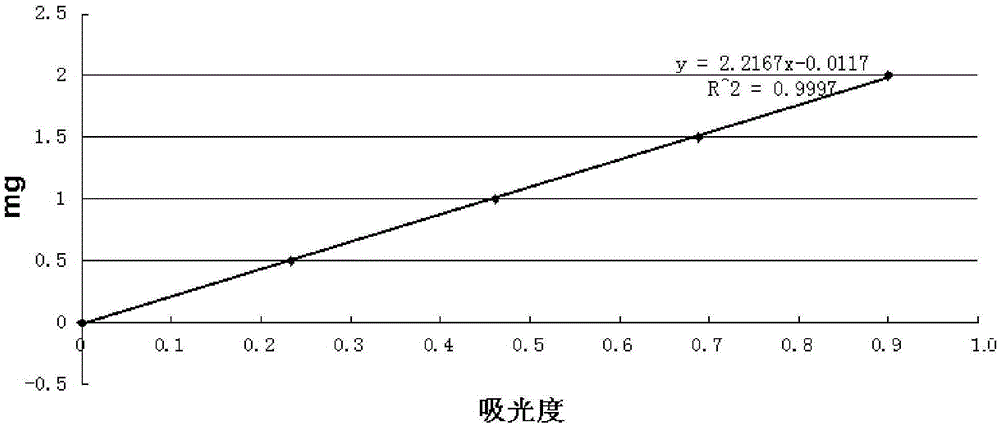

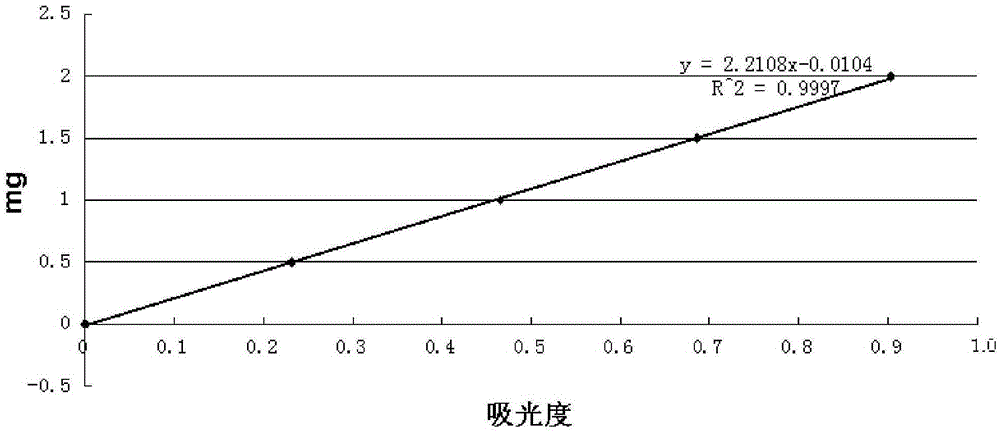

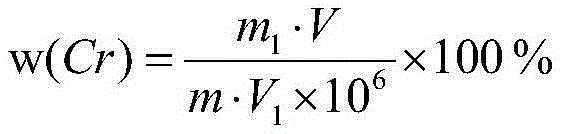

Image

Examples

Embodiment

[0078] Since there is no standard sample of vanadium-chromium hydrogen storage alloy, a standard sample was simulated by using vanadium-iron and potassium dichromate standard reagents according to the main components of the vanadium-chromium hydrogen storage alloy sample. Preparation method of analog standard sample of vanadium-chromium hydrogen storage alloy: Weigh 28.8122 grams of vanadium-iron sample (V=72.40%) and 11.3077 grams of potassium dichromate, mix and shake well. The vanadium content of the standard sample is 51.99%, and the chromium content is 9.96%.

[0079] Get vanadium chromium hydrogen storage alloy simulation standard sample and vanadium chromium hydrogen storage alloy sample, take quality and be 0.2000 grams, carry out three parallel measurements according to the inventive method, check the precision and the accuracy of the inventive method, the obtained results are shown in the table 5.

[0080] Table 5 Chromium analysis results in hydrogen storage alloys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com