Photoelectric sensor and application thereof, and preparation method of working electrode

A photoelectric sensor and working electrode technology, applied in the field of photoelectric sensing, can solve the problems of low sensitivity, high toxicity of reagents, complicated methods, etc., and achieve the effects of simple detection process, low cost, and improved generation ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

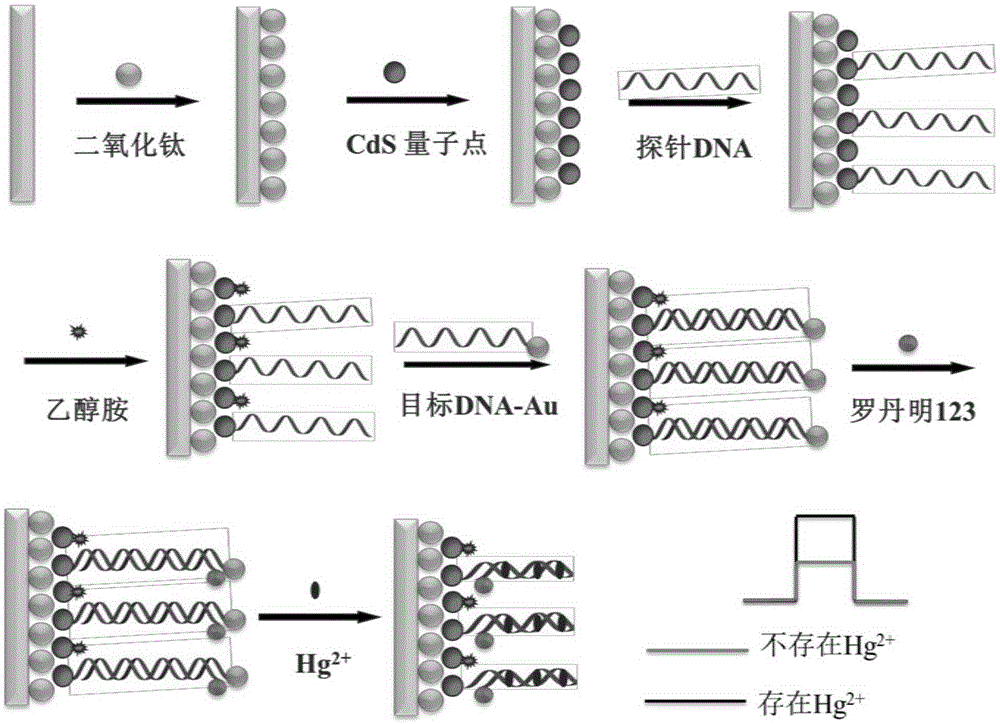

[0057] Such as figure 1 as shown, figure 1 It is a schematic flowchart of a method for preparing a working electrode of a photoelectric sensor proposed by the present invention.

[0058] refer to figure 1 , the preparation method of the working electrode of a kind of photoelectric sensor that the present invention proposes, comprises the steps:

[0059] S1. After cleaning the ITO electrode with acetone, add it to the first mixed solution for cleaning. In the first mixed solution, the concentration of sodium hydroxide is 0.8mol / L, and the volume ratio of ethanol and water is 3:2; then wash it with water Finally, the ITO electrode was cleaned for 18 minutes, and dried at 75°C for 13 hours to obtain electrode A;

[0060] S2. Add the titanium dioxide colloidal solution dropwise on the surface of electrode A, wherein the preparation method of the titanium dioxide colloidal solution is to ultrasonically disperse 8 mg of titanium dioxide powder in 6 mL of deionized water, every 1 ...

Embodiment 2

[0066] The preparation method of the working electrode of a kind of photoelectric sensor that the present invention proposes, comprises the steps:

[0067] S1. After cleaning the ITO electrode with acetone, add it to the first mixed solution for cleaning. In the first mixed solution, the concentration of sodium hydroxide is 1.2mol / L, and the volume ratio of ethanol and water is 2:3; then wash it with water Finally, the ITO electrode was cleaned for 12 minutes, and dried at 85°C for 10 hours to obtain electrode A;

[0068] S2. Add the titanium dioxide colloidal solution dropwise on the surface of electrode A, wherein the preparation method of the titanium dioxide colloidal solution is to ultrasonically disperse 10 mg of titanium dioxide powder in 6 mL of deionized water, every 1 cm 2 Add 0.06mL of titanium dioxide colloidal solution dropwise on the modified surface of electrode A, dry and then calcinate at 460°C for 0.5h, then cool to room temperature to obtain electrode B;

...

Embodiment 3

[0074] The preparation method of the working electrode of a kind of photoelectric sensor that the present invention proposes, comprises the steps:

[0075] S1. Clean the ITO electrode with acetone, and then add it to the first mixed solution for cleaning. In the first mixed solution, the concentration of sodium hydroxide is 1mol / L, and the volume ratio of ethanol and water is 1:1; then wash it with water , the cleaning time of the ITO electrode is 15 minutes, and the electrode A is obtained by drying at 80°C for 12 hours;

[0076] S2, drop the titanium dioxide colloidal solution on the surface of electrode A, wherein the preparation method of the titanium dioxide colloidal solution is to ultrasonically disperse 6 mg of titanium dioxide powder in 6 mL of deionized water, every 1 cm 2 Add 0.08mL of titanium dioxide colloidal solution dropwise to the modified surface of electrode A, dry and then calcinate at 450°C for 0.5h, then cool to room temperature to obtain electrode B;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com