Preparation method for high-haze composite transparent conductive electrode

A transparent conductive electrode, high haze technology, applied in circuits, photovoltaic power generation, electrical components, etc., to achieve the effect of easy industrialization, improved conversion efficiency, and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

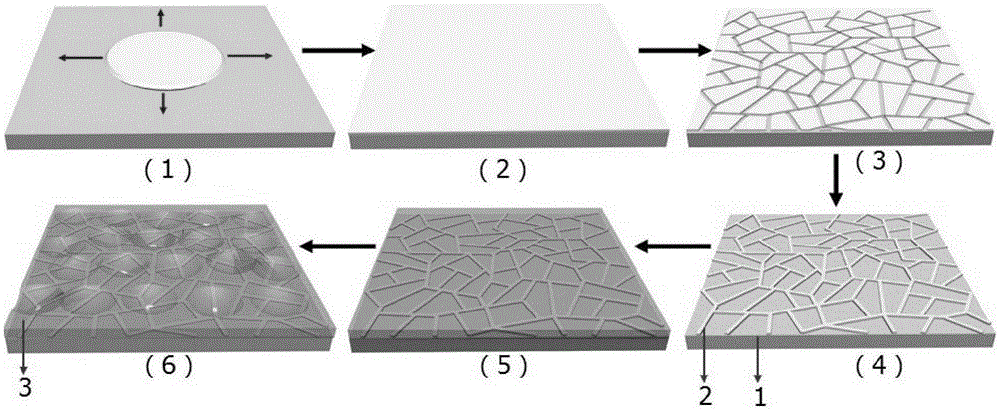

[0054] Such as figure 1 As shown, this embodiment provides a method for preparing a high-haze composite transparent conductive electrode, that is, a method for preparing a composite transparent conductive electrode based on a metal grid and a surface textured metal oxide, wherein (1) represents a crack Deposition of template liquid, (2) represents the formation of cracked templates, (3) represents the deposition of metal thin films, (4) represents the removal of cracked templates, that is, the formation of metal grids, (5) represents the formation of metal oxides Deposition, (6) represents the etching of metal oxides, that is, the formation of metal grids and surface textured metal oxide composite transparent conductive electrodes, where: 1 represents the metal network line, 2 represents the mesh, and 3 represents the surface texture Metal oxide.

[0055] The detailed process of each step is as follows:

[0056] (1) Preparation of cracking fluid and deposition of cracking fi...

Embodiment 2

[0070] This embodiment provides a method for preparing a composite transparent conductive electrode based on a metal grid and a surface textured metal oxide. figure 1 , where (1) represents the deposition of the cracked template solution, (2) represents the formation of the cracked template, (3) represents the deposition of the metal film, and (4) represents the removal of the cracked template, that is, the metal grid Formation, (5) represents the deposition of metal oxides, (6) represents the etching of metal oxides, that is, the formation of metal grids and surface textured metal oxide composite transparent conductive electrodes, wherein: 1 represents metal network lines, 2 represents the mesh, 3 represents the surface textured metal oxide.

[0071] The detailed process of each step is as follows:

[0072] (1) Preparation of cracking fluid and deposition of cracking film

[0073] Using egg white liquid as raw material, add deionized water (the volume ratio of deionized wat...

Embodiment 3

[0086] This embodiment provides a method for preparing a composite transparent conductive electrode based on a metal grid and a surface textured metal oxide. figure 1 , where (1) represents the deposition of the cracked template solution, (2) represents the formation of the cracked template, (3) represents the deposition of the metal film, and (4) represents the removal of the cracked template, that is, the metal grid Formation, (5) represents the deposition of metal oxides, (6) represents the etching of metal oxides, that is, the formation of metal grids and surface textured metal oxide composite transparent conductive electrodes, wherein: 1 represents metal network lines, 2 represents the mesh, 3 represents the surface textured metal oxide.

[0087] The detailed process of each step is as follows:

[0088] (1) Preparation of cracking fluid and deposition of cracking film

[0089] Using egg white liquid as raw material, add deionized water (wherein the volume ratio of deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com