A kind of synthetic preparation method of solar cell diffusion barrier isolation layer

A solar cell and isolation layer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex process, high cost, cross-doping of phosphorus and boron, etc., to simplify subsequent processes, improve reliability, and reduce cross-doping Diffusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

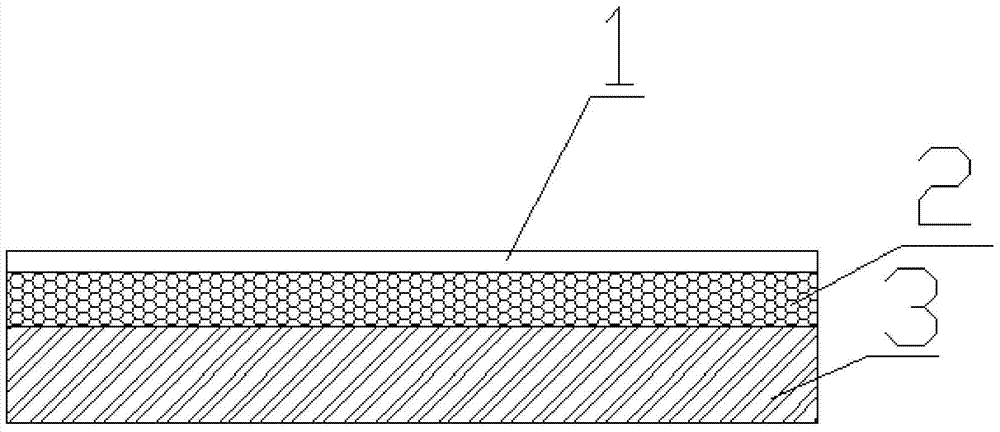

Image

Examples

Embodiment 1

[0026] This embodiment discloses a method for synthesizing and preparing a solar cell diffusion barrier isolation layer, the method comprising the following steps:

[0027] (1) Weigh 21.0434g TEOS (0.1mol), 1.44g water (0.08mol), 9.015g isopropanol (0.15mol), 9.2512g PGMEA (0.07mol), mix the above components evenly, and add in the bottom flask.

[0028] (2) Add 2.5252g amberlyst 15 as a solid catalyst to the above reaction mixture, the pH of the above solid catalyst is 2, add a stirring bar to the above single-necked round bottom flask, put it in an oil bath stirrer at 60°C, and react for 5h.

[0029] (3) After the reaction was completed, the reaction mixture was filtered to remove the solid catalyst, and isopropanol, PGMEA, water, etc. were removed by rotary evaporation to obtain the barrier and isolation layer product. The viscosity of the product was tested, and the viscosity was 43.16 cps. The product was collected for use.

Embodiment 2

[0031] A method for synthesizing and preparing a solar cell diffusion barrier barrier layer is disclosed in Example 2. The specific steps of the method are:

[0032] (1) Use a beaker to weigh 1.8g deionized water (0.1mol), 9.015g isopropanol (0.15mol), 4.2087g TEOS (0.02mol), 14.5551g MTEOS (0.08mol) and mix well;

[0033] (2) Weigh 1.0522g amberlyst16 as a solid catalyst (5% equivalent to 0.1mol TEOS), the pH of the solid catalyst is 3, the above solid catalyst is put into a round bottom flask, and then the mixture in (1) is also added Add a stirring bar to the round bottom flask, put the flask into an oil bath stirrer; set the temperature of the oil bath stirrer to 80°C, and react for 4 hours.

[0034] (3) After the above-mentioned reaction is finished, filter out the above-mentioned solid catalyst with a suction filter funnel, and the reaction solution weighs 135.936g.

[0035] (4) Rotate the above reaction solution at a temperature of 60° C. for 1 hour to remove isopropan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com