Patterning method of quantum dot layer and preparation method of quantum dot color film

A technology of quantum dot layer and patterning, which is applied in the direction of photo-plate making process of pattern surface, photo-plate making process coating equipment, optical mechanical equipment, etc. Problems such as low resolution, to achieve the effect of simplifying the surface chemical environment, improving display resolution, and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail the preferred embodiments of the present invention and the accompanying drawings.

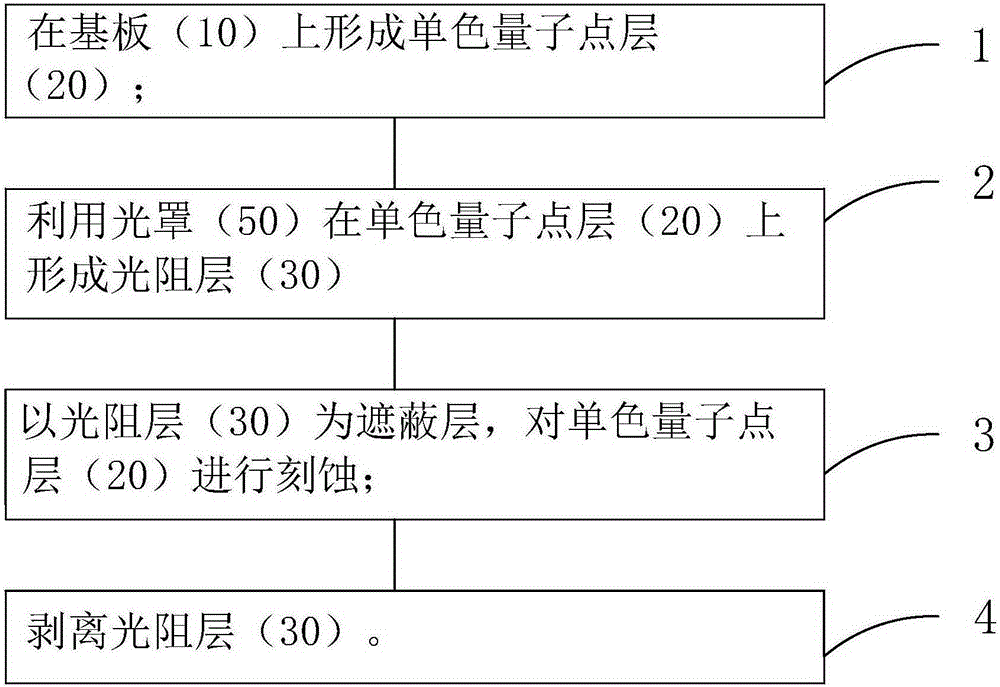

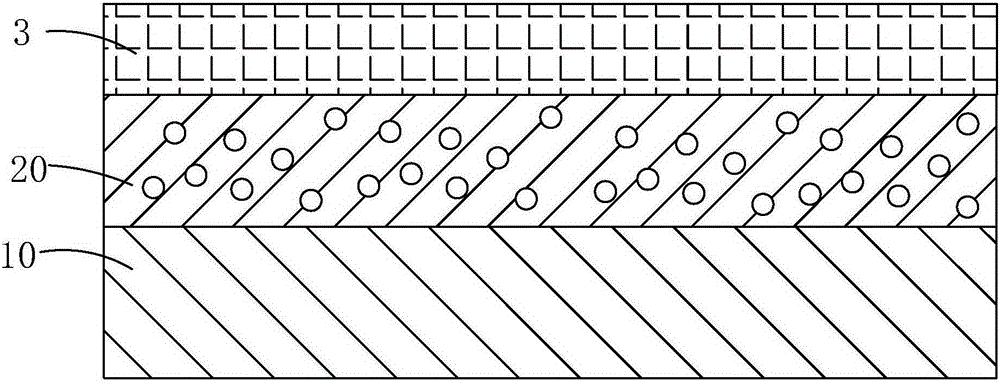

[0038] See Figure 1-7 , The present invention first provides a method for patterning a quantum dot layer, which includes the following steps:

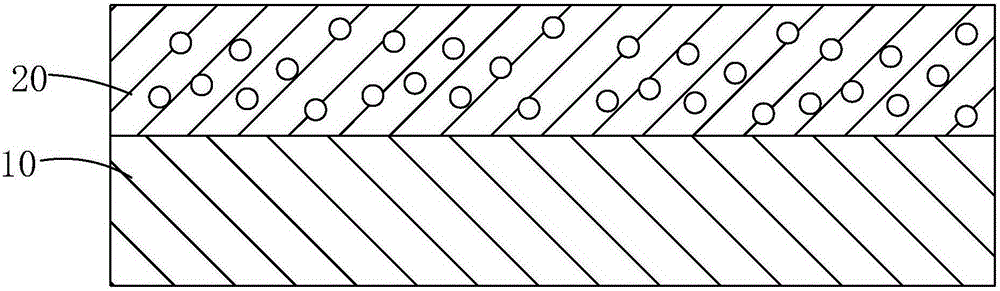

[0039] Step 1, such as figure 2 As shown, a substrate 10 is provided, a monochromatic quantum dot glue is coated on the substrate 10, and after curing, a monochromatic quantum dot layer 20 is obtained;

[0040] Specifically, the monochromatic color refers to various monochromatic colors such as red, green, or blue, and the monochromatic quantum dot layer 20 emits monochromatic light of the corresponding color under light excitation, such as red light (with a wavelength of 630 -690nm), green light (wavelength 500-560nm), or blue light (wavelength 430-480nm).

[0041] Specifically, the monochromatic quantum dot glue inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com