Exhaust gas treatment equipment

A technology for treating device and waste gas, applied in the combustion method, combustion type, incinerator, etc., can solve the problem of difficult and harmless, and achieve the effect of reliable high temperature, reliable combustion, and improved cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

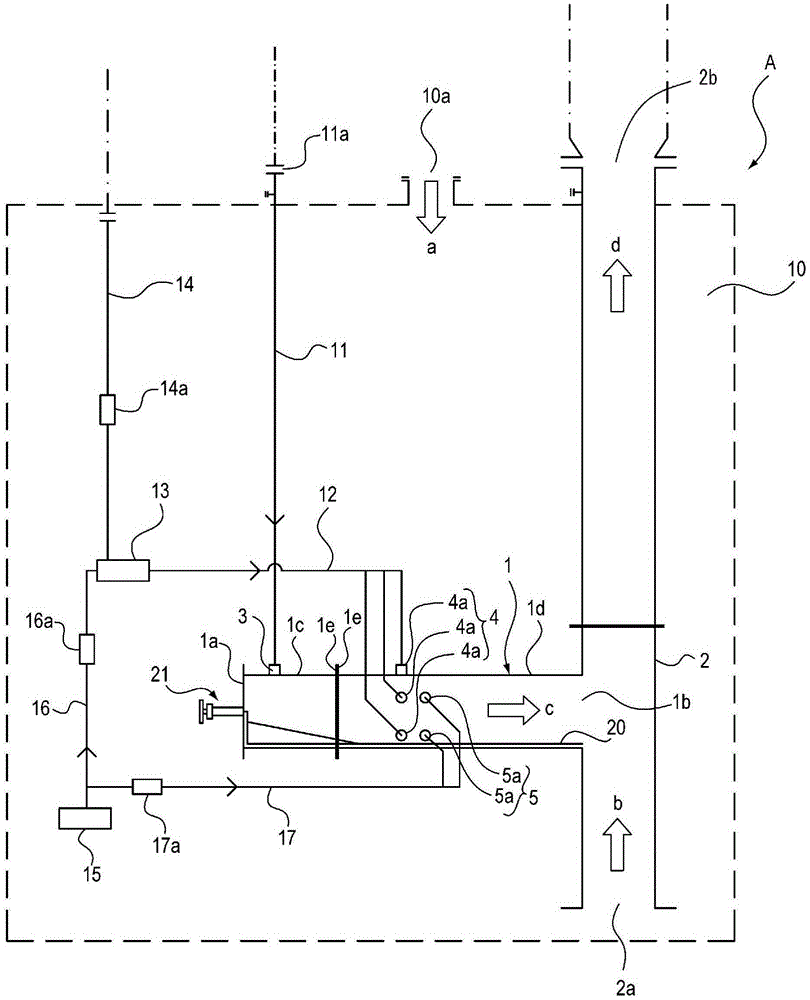

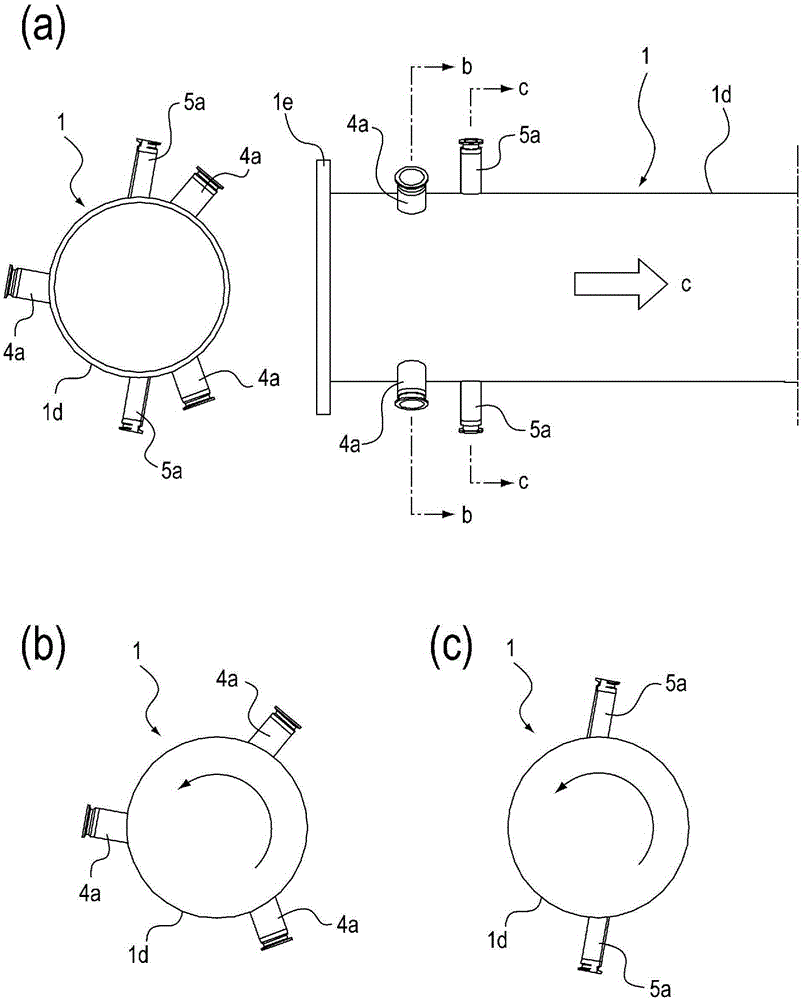

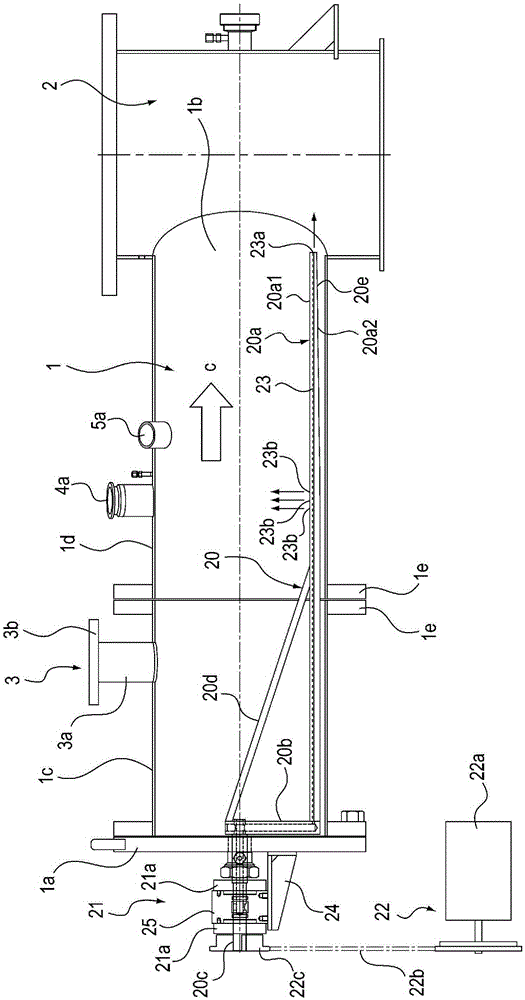

[0034] Hereinafter, the processing device of the present invention will be described. The processing device of the present invention uses silane, disilane, diborane, phosphine, arsenic trihydride, nitrogen trifluoride, silicon fluoride, and silicon chloride generated from the manufacturing process of semiconductors, liquid crystal panels, or solar cells. Exhaust gases such as toxic special material gases, carbon tetrafluoride, sulfur hexafluoride, etc., which have a negative impact on the global environment, and explosive hydrogen gas are burned or decomposed to be harmless and discharged.

[0035] The processing device of the present invention is configured to supply exhaust gas that needs to be harmless and supply combustion-supporting gas into the combustion chamber, and ignite the burner to keep the combustion chamber at a high temperature, thereby enabling the supplied exhaust gas to burn without Or decompose and become harmless at high temperature. In addition, the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com