Enoxaparin injection preparation and industrial production method thereof

A technology for injection preparations and enoxaparin, which is applied in the direction of pharmaceutical formulations, medical preparations with no active ingredients, medical preparations containing active ingredients, etc., which can solve the problem that enoxaparin sodium injection is prone to deterioration and cannot fully improve the product Stability, instability to heat and oxidants, etc., to achieve superior stability, avoid impurities, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

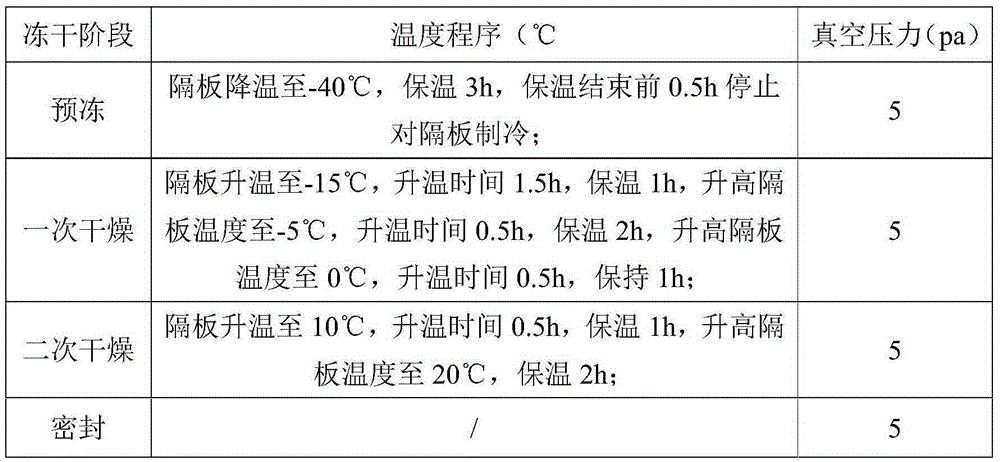

[0033] Embodiment 1 Preparation of enoxaparin injection preparation of the present invention

[0034] Preparation prescription: enoxaparin sodium 800g, mannitol 40g, activated carbon 4g, add water for injection to 8000ml

[0035] Preparation method: 1) Take 80% of the prescribed amount of water for injection, boil it and keep it in the batching tank. When the temperature drops below 60°C, add enoxaparin sodium and mannitol and stir to dissolve it, and add 5.0% sodium hydroxide Or hydrochloric acid to adjust the pH value to 6.0-7.0; 2) Add water for injection to the full amount, stir for 30 minutes, add medicinal charcoal at a dosage of 0.05% (w / v), and absorb for 10 minutes below 60°C; 3) The liquid is heated through 0.45 The μm filter element is used for coarse filtration and decarbonization, and the filtrate is transferred to the dilution tank; 4) Sampling and inspection of intermediate products; 5) After passing the test, fine filtration is carried out with a 0.22 μm filter...

Embodiment 2

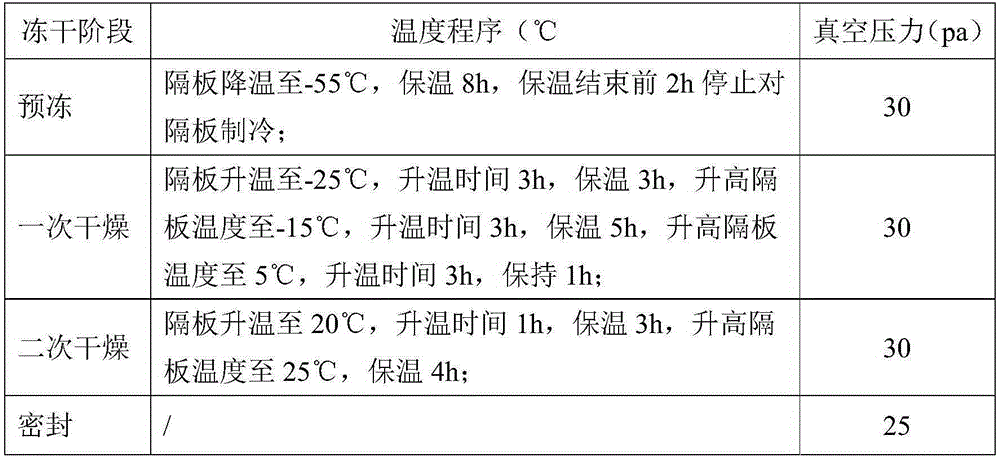

[0038] Embodiment 2 Preparation of enoxaparin injection preparation of the present invention

[0039] Preparation prescription: enoxaparin sodium 800g, mannitol 40g, activated carbon 4g, add water for injection to 8000ml

[0040] Preparation method: 1) Take 80% of the prescribed amount of water for injection, boil it and keep it in the batching tank. When the temperature drops below 60°C, add enoxaparin sodium and mannitol and stir to dissolve it, and add 5.0% sodium hydroxide Or hydrochloric acid to adjust the pH value to 6.0-7.0; 2) Add water for injection to the full amount, stir for 30 minutes, add medicinal charcoal at a dosage of 0.05% (w / v), and absorb for 10 minutes below 60°C; 3) The liquid is heated through 0.45 The μm filter element is used for coarse filtration and decarbonization, and the filtrate is transferred to the dilution tank; 4) Sampling and inspection of intermediate products; 5) After passing the test, fine filtration is carried out with a 0.22 μm filter...

Embodiment 3

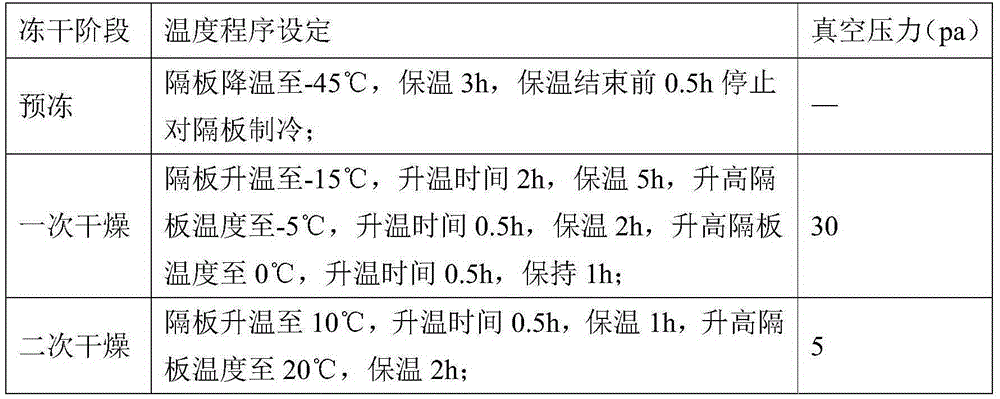

[0043]Example 3 Preparation of Enoxaparin Injection Preparation of the Present Invention

[0044] Preparation prescription: enoxaparin sodium 800g, mannitol 40g, activated carbon 4g, add water for injection to 8000ml

[0045] Preparation method: 1) Take 80% of the prescribed amount of water for injection, boil it and keep it in the batching tank. When the temperature drops below 60°C, add enoxaparin sodium and mannitol and stir to dissolve it, and add 5.0% sodium hydroxide Or hydrochloric acid to adjust the pH value to 6.0-7.0; 2) Add water for injection to the full amount, stir for 30 minutes, add medicinal charcoal at a dosage of 0.05% (w / v), and absorb for 10 minutes below 60°C; 3) The liquid is heated through 0.45 The μm filter element is used for coarse filtration and decarbonization, and the filtrate is transferred to the dilution tank; 4) Sampling and inspection of intermediate products; 5) After passing the test, fine filtration is carried out with a 0.22 μm filter mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com