Ultrasonic-modulation micro electro-chemical machining experiment system

An electrochemical machining and experimental system technology, applied in the field of ultrasonic modulation micro-electrochemical machining experimental system, can solve the problems of low stability, decreased machining accuracy, low machining efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

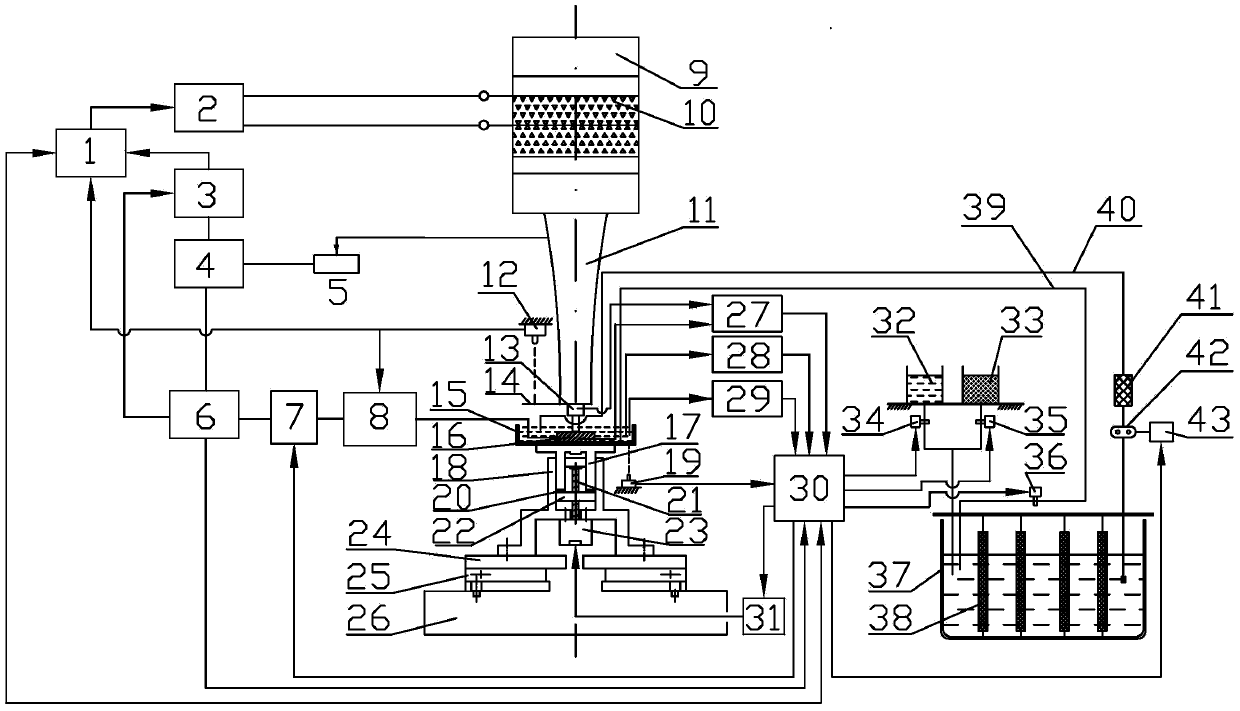

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0037] The schematic diagram of the ultrasonic modulation micro-electrochemical processing experimental system of the present invention is shown in Figure 1, including an ultrasonic vibration system, an electrolytic processing system, a synchronous chopper system, a servo feed system, a short circuit protection system, an electrolyte circulation system, and an online parameter adjustment system .

[0038] Among them, the ultrasonic vibration system includes an ultrasonic power supply 2, a piezoelectric transducer 9, a piezoelectric ceramic sheet 10, a horn 11, and a tool electrode 13; the electrolytic processing system includes a digital storage oscilloscope 3, a pulse power supply 4, and a current limiting resistor 5 , current sensor 6, voltage sensor 27, processing workpiece 16; Synchronous chopper system includes synchronous chopper 8, laser micro-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com