Polyacrylate/nano SiO2 hybrid emulsion with high coating film hardness and tolerance and preparation method for polyacrylate/nano SiO2 hybrid emulsion and application of polyacrylate/nano SiO2 hybrid emulsion

A technology of polyacrylate emulsion and polyacrylate, applied in the direction of coating, can solve the problems of poor storage stability, high production cost, poor coating film performance, etc., to improve transparency and gloss, and improve storage stability , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

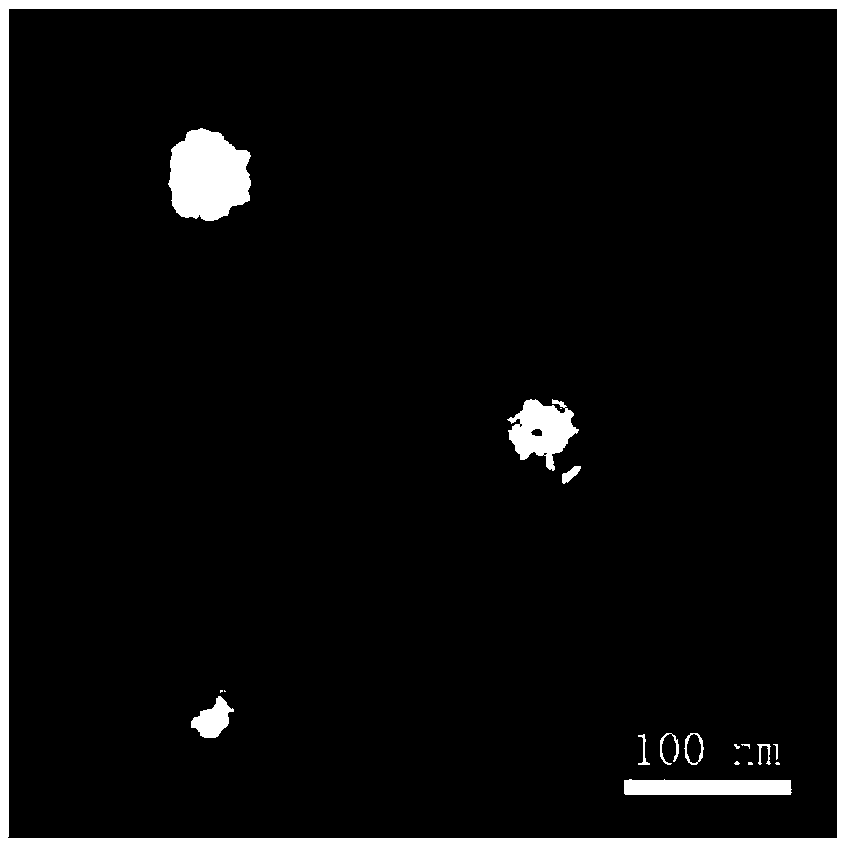

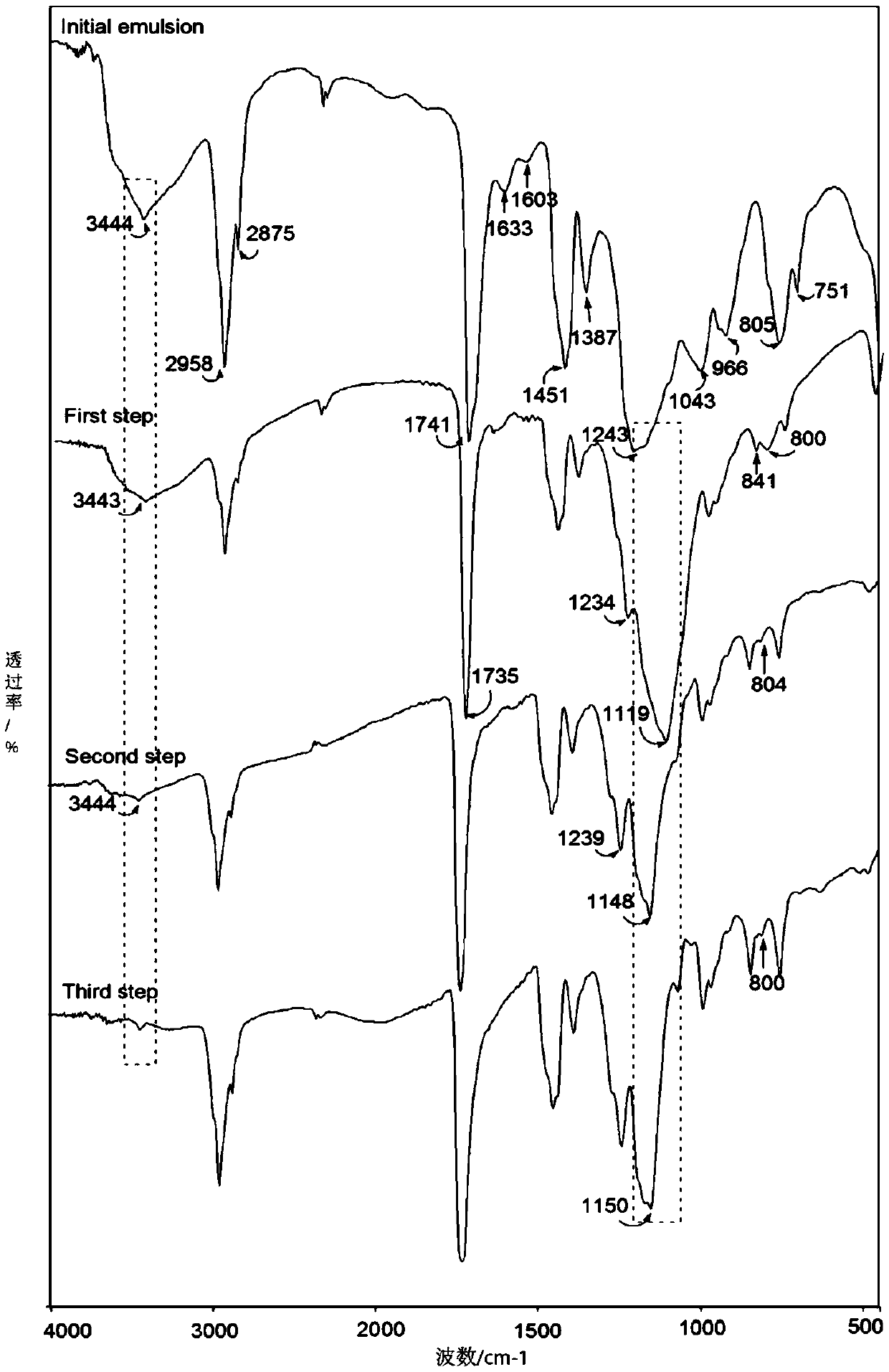

Image

Examples

Embodiment 1

[0038] (1) Preparation of vinyl siloxane modified polyacrylate emulsion:

[0039] formula:

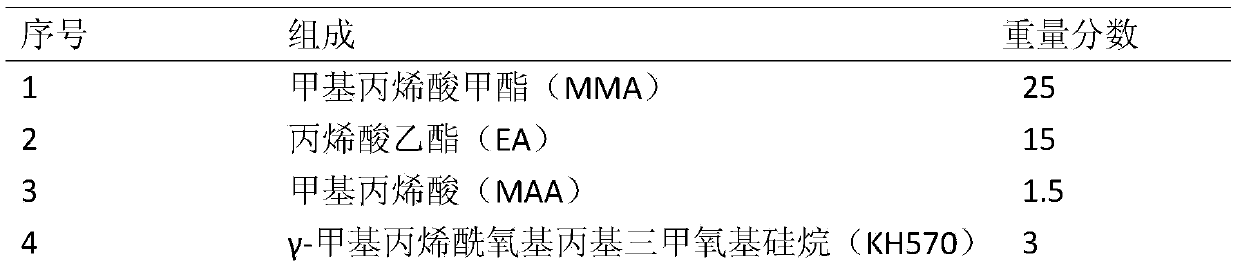

[0040] Table 1a

[0041]

[0042]

[0043] Preparation method: firstly mix vinyl siloxane and all acrylate monomers uniformly according to the formula to prepare acrylate monomer mixture; add emulsifier into a 500mL four-necked flask equipped with a thermometer, condenser tube, stirring paddle and constant pressure funnel (anionic emulsifier SDS and nonionic emulsifier OP‐10, NaHCO 3 And appropriate amount of deionized water, heat up to 75-80 ° C, then add 10% initiator potassium persulfate (KPS), after 20 minutes of heat preservation, start to drop 10% acrylate monomers (MMA, EA and MAA) to prepare seed emulsion , after the system is in the blue phase and stabilizes for 30 minutes, continue to drop the remaining aqueous solution of the acrylate monomer and the initiator (first made into a 10% aqueous solution), after the addition is completed, heat up to 82-85°C for 1 hour, co...

Embodiment 2

[0057] (1) Preparation of vinyl siloxane modified polyacrylate emulsion:

[0058] formula:

[0059] Table 2a

[0060]

[0061] Preparation method: firstly mix vinyl siloxane and all acrylate monomers uniformly according to the formula to prepare acrylate monomer mixture; add emulsifier into a 500mL four-necked flask equipped with a thermometer, condenser tube, stirring paddle and constant pressure funnel , NaHCO 3 Add appropriate amount of deionized water, heat up to 75-80°C, then add 20% initiator, after 10 minutes of heat preservation, start to drop 5% acrylate monomer to prepare seed emulsion, wait until the system is in blue phase and stabilize for 10 minutes, continue to drop The remaining acrylate monomer and the aqueous solution of the initiator (prepared as a 10% aqueous solution), after the dropwise addition is completed, the temperature is raised to 82-85° C. and kept for 1 hour, and the temperature is lowered and filtered out.

[0062] Emulsion properties: ave...

Embodiment 3

[0072] (1) Preparation of vinyl siloxane modified polyacrylate emulsion:

[0073] formula:

[0074] Table 3a

[0075]

[0076]

[0077] Preparation method: firstly mix vinyl siloxane and all acrylate monomers uniformly according to the formula to prepare acrylate monomer mixture; add emulsifier into a 500mL four-neck flask equipped with a thermometer, condenser tube, stirring paddle and constant pressure funnel , NaHCO 3 and an appropriate amount of deionized water, heat up to 75-80°C, then add 30% initiator, after 30 minutes of heat preservation, start to add 15% acrylate monomer mixture dropwise to prepare seed emulsion, wait for the system to become blue phase and stabilize for 20 minutes, continue to drop Add the remaining acrylate monomer mixture and the aqueous solution of the initiator (prepared into a 10% aqueous solution first), after the dropwise addition, raise the temperature to 82-85°C and keep it warm for 1 hour, then cool down and filter out.

[0078] E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com