Differential parallel optical chromatographic microscopic measuring device and method

An optical tomography and microscopic measurement technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of reducing measurement efficiency, limiting the application scope of structured illumination obvious microtechnology, affecting measurement accuracy, etc. The effect of measurement, three-dimensional fast and precise measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

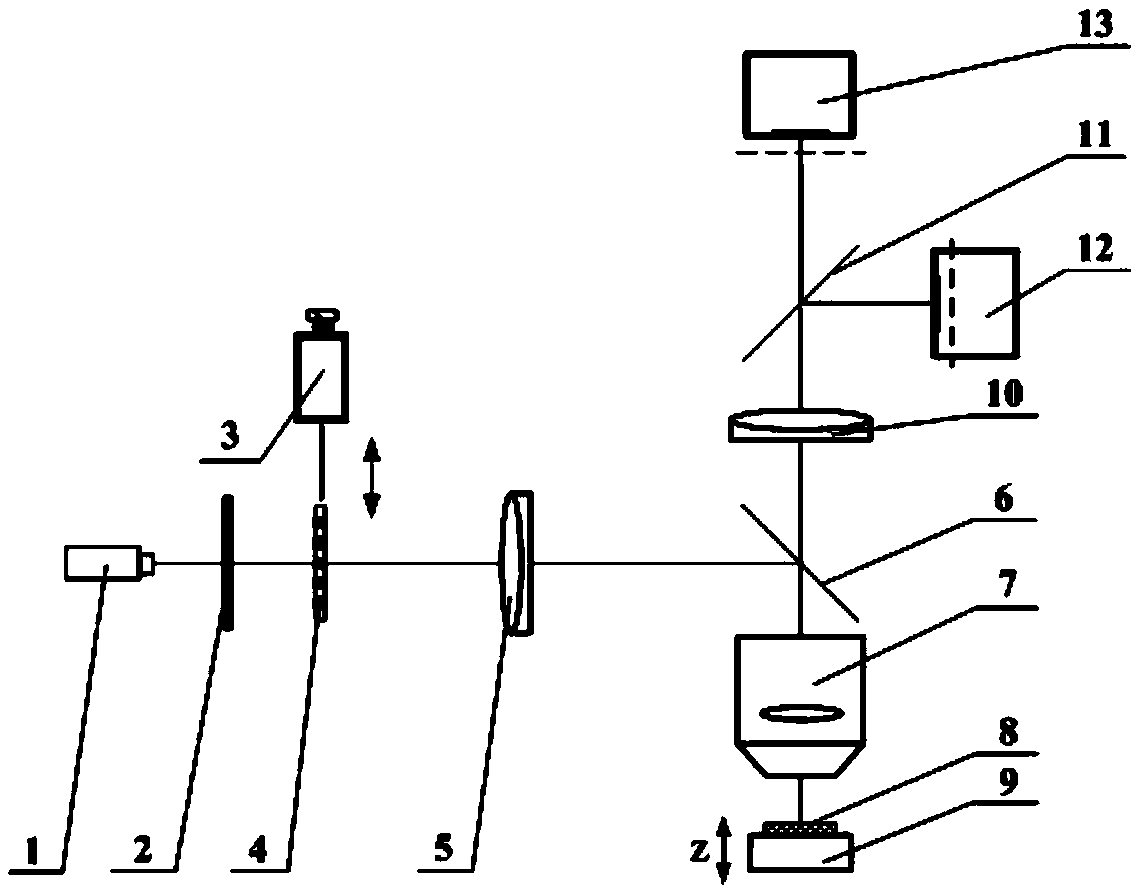

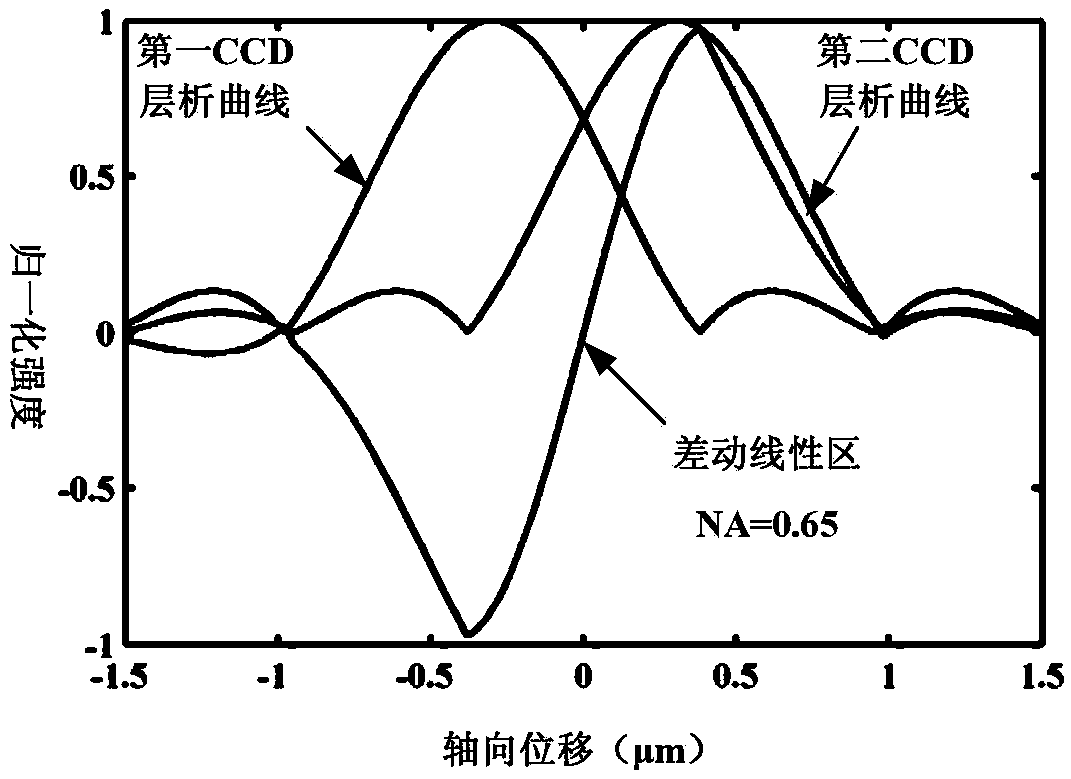

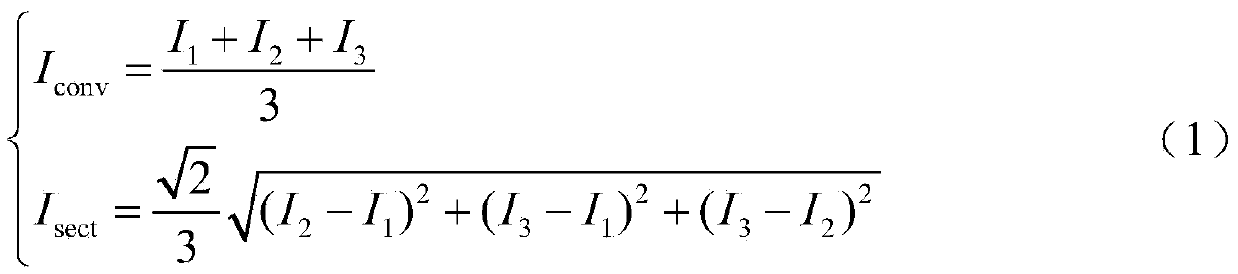

[0030] The present invention utilizes the wide field line tomography theory of differential detection structured light illumination. In this device, one-dimensional transmission grating 4 is used to modulate the incident quasi-parallel light to form stripe grating illumination, and then through the incoherent optical imaging filter system, the grating stripe The miniature image is transferred to the focal plane of the microscope objective lens 7, and the cosine intensity distribution illumination stripes are generated by spatial filtering to modulate the fluctuation of the sample surface; The first CCD 12 at a position close to the focal plane of the tube lens 10 and the second CCD 13 at a position far from the focal plane perform light intensity detection respectively. First, when the CCD quasi-focus detection is set, the image field I is collected 1 ; Move the lateral position of the illumination straight stripe grating by the stepper motor 3, move the 1 / 3 and 2 / 3 displaceme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com