Corncob-based porous carbon material, and preparation method and application thereof

A technology of porous carbon materials and corn cobs, applied in the field of material science, can solve problems such as complex preparation processes, and achieve the effects of simple processing, wide application, and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put 3g of corncobs cut into short sections into a beaker, add 3g of KOH, then add a small amount of water to cover the corncobs, and soak for 8h. It was dried in an oven at 80°C for 6h, and the dried residue was carbonized at 750°C for 1.5h in an argon atmosphere, the gas flow rate was 0.5L / min, and the heating rate was 5°C / min. The obtained product was washed 5 times with 2M hydrochloric acid, then washed with water until neutral, and dried at 80° C. for 12 hours to obtain a corncob-based porous carbon material.

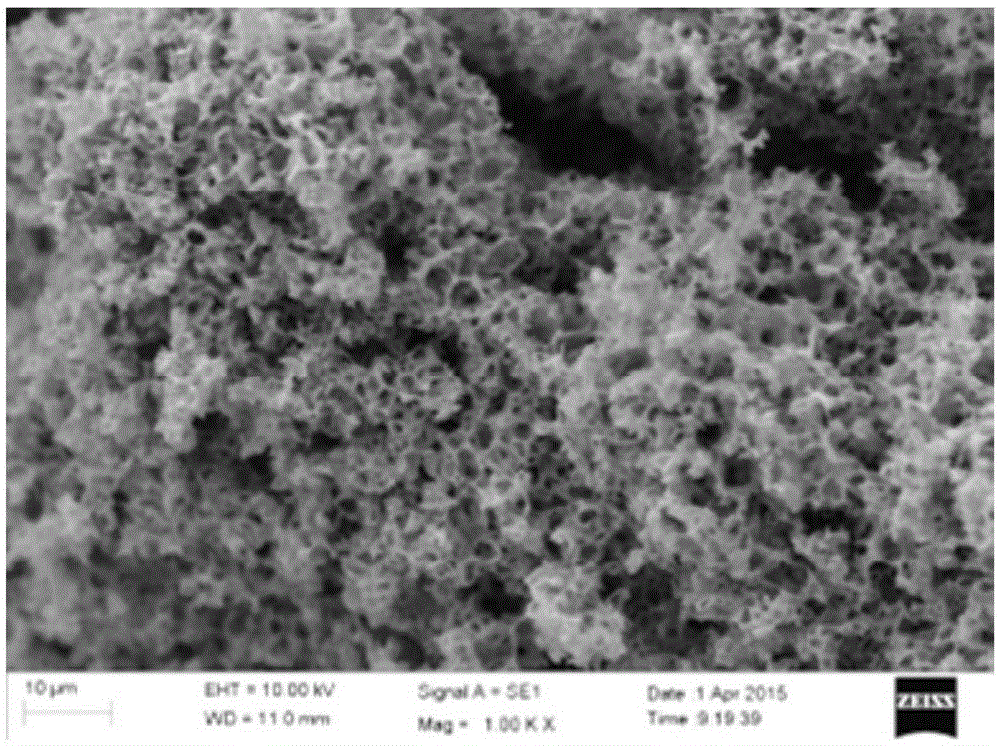

[0037] from figure 1 It can be seen that the prepared corncob-based porous carbon material has abundant pores, and the specific surface area of the porous carbon material is: 1151.2m 2 / g.

Embodiment 2

[0039] Put 3 g of short-cut corn cobs into a beaker, mix with KOH solid at a mass ratio of 0.5:1, soak in water for 10 h, and then dry at 100 °C for 10 h. Put the dried sample into a boat-shaped sample tank, and carbonize at 750 °C for 1.5 h in a nitrogen atmosphere, with a gas flow rate of 0.5 L / min and a heating rate of 5 °C / min. The obtained product was washed 5 times with 2M hydrochloric acid, then washed with water until neutral, and dried at 80° C. for 12 hours to obtain a corncob-based porous carbon material.

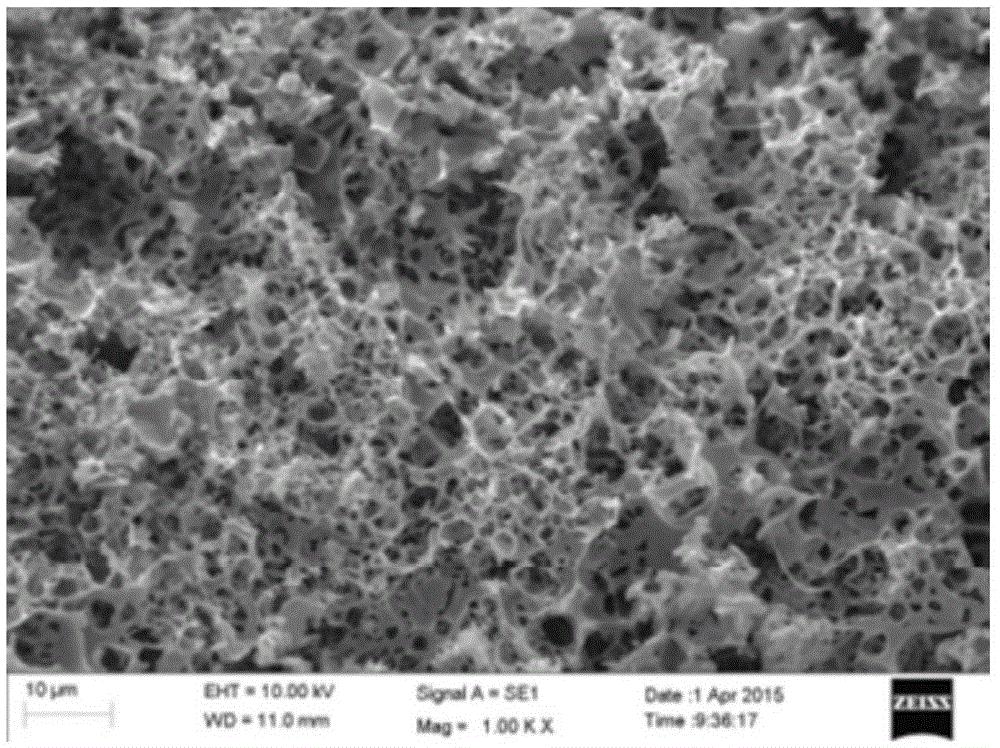

[0040] from image 3 It can be seen that the prepared corncob-based porous carbon material has abundant pores, and the specific surface area of the porous carbon material is: 1182.7m 2 / g. Corncob porous carbon materials were successfully prepared by this method.

[0041] The obtained corncob-based porous carbon material was used as raw material (80wt%), mixed with acetylene black (10wt%) and PTFE (10wt%) to make a semi-dry slurry, pressed on foamed nickel (...

Embodiment 3

[0043] Put 3 g of short-cut corn cobs into a beaker, mix with KOH solid at a mass ratio of 0.5:1, soak in water for 10 h, and then dry at 100 °C for 8 h. Put the dried sample into the boat-shaped sample tank, and in the atmosphere of argon, first carbonize at 300°C for 1h, the heating rate is 5°C / min, then carbonize at 750°C for 1.5h, the gas flow rate is 0.5L / min, and heat up The rate was 3°C / min. The obtained product was washed 5 times with 2M hydrochloric acid, then washed with water until neutral, and dried at 80°C for 12 hours to obtain a corncob-based porous carbon material with a specific surface area of 1577.7m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com