Method for separating chloride from perchloride

A high chloride and chloride technology, applied in the disproportionation separation/purification of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of difficult temperature control, great harm to human health, and inability to separate hexachlorobenzene. , to achieve the effect of improving purity and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

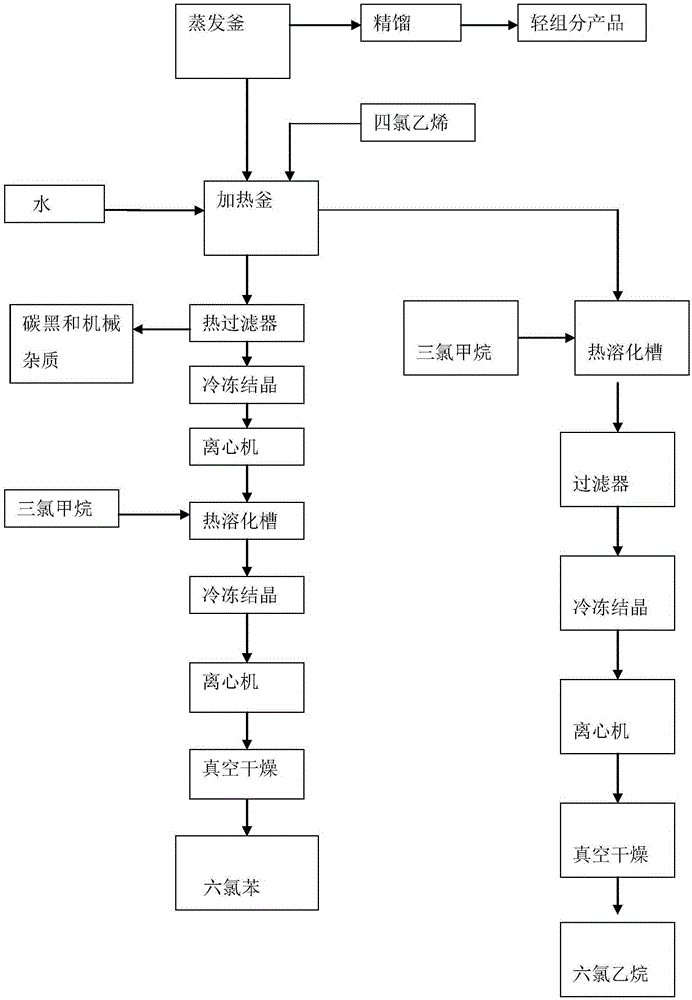

Method used

Image

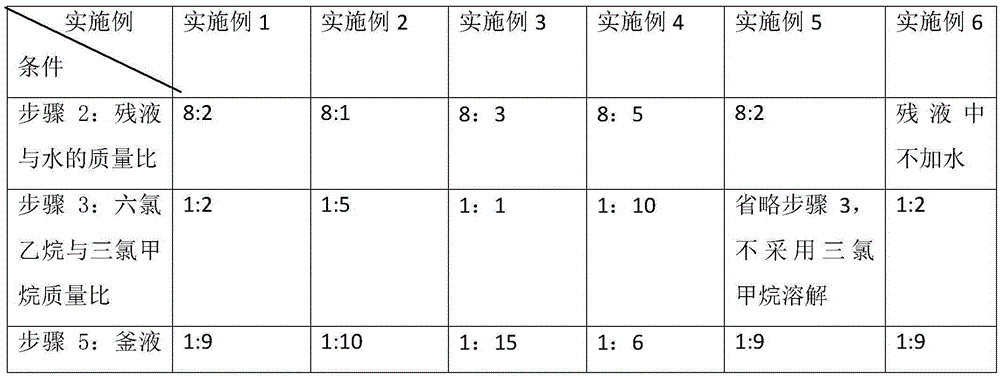

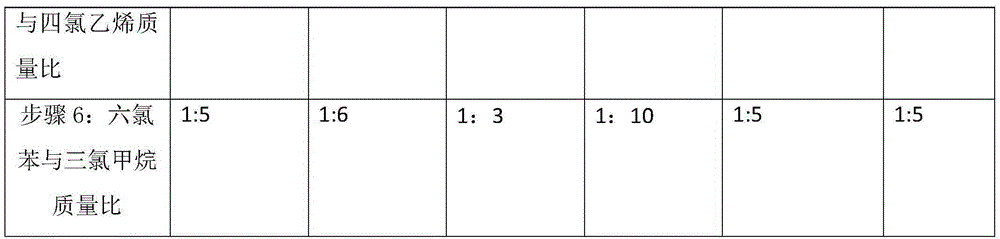

Examples

Embodiment 1

[0035] This embodiment provides a method for separating chlorides from high chlorides, which mainly includes the following steps:

[0036] (1) Put the high chloride waste into the evaporator, heat the jacket with 0.3Mpa saturated steam, control the evaporation temperature at 140°C, and finally reach 150°C for half an hour, after the evaporation is complete, the evaporated liquid chloride Rectification to separate carbon tetrachloride and tetrachloroethylene;

[0037] (2) Transfer the residual liquid evaporated in step 1 to the sublimation kettle, add water and heat to boiling, and at the same time feed hot nitrogen, the pressure of the hot nitrogen in the sublimation kettle is kept at 0.3Mpa, and the hot nitrogen is heated by heat transfer oil to conduct heat The oil temperature is controlled at 270°C, and the mass ratio of the raffinate to water is 8:2;

[0038] (3) The hexachloroethane sublimated in step 2 is passed into a chloroform dissolving tank for dissolution, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com