Rotary carbonizing furnace

A technology of rotary furnace and carbonization furnace, applied in the direction of rotary carbonization furnace, coke oven, special form of dry distillation, etc., can solve problems such as pollution, safety hazards, leakage, etc., and achieve the effect of improving economy, improving safety and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

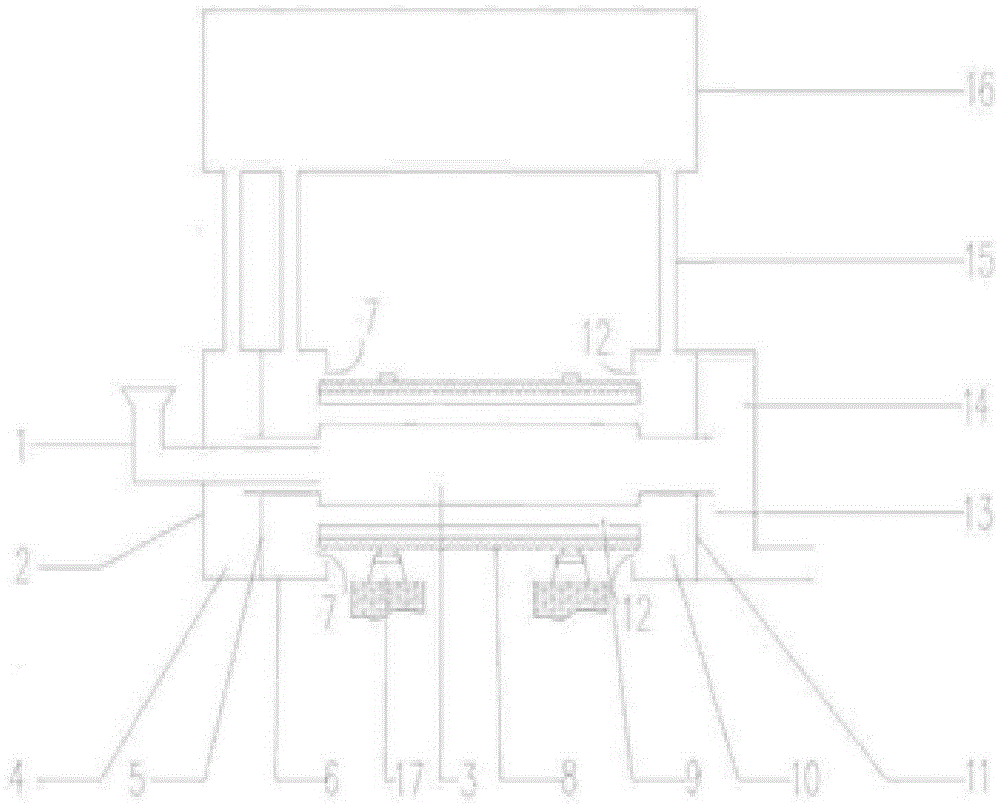

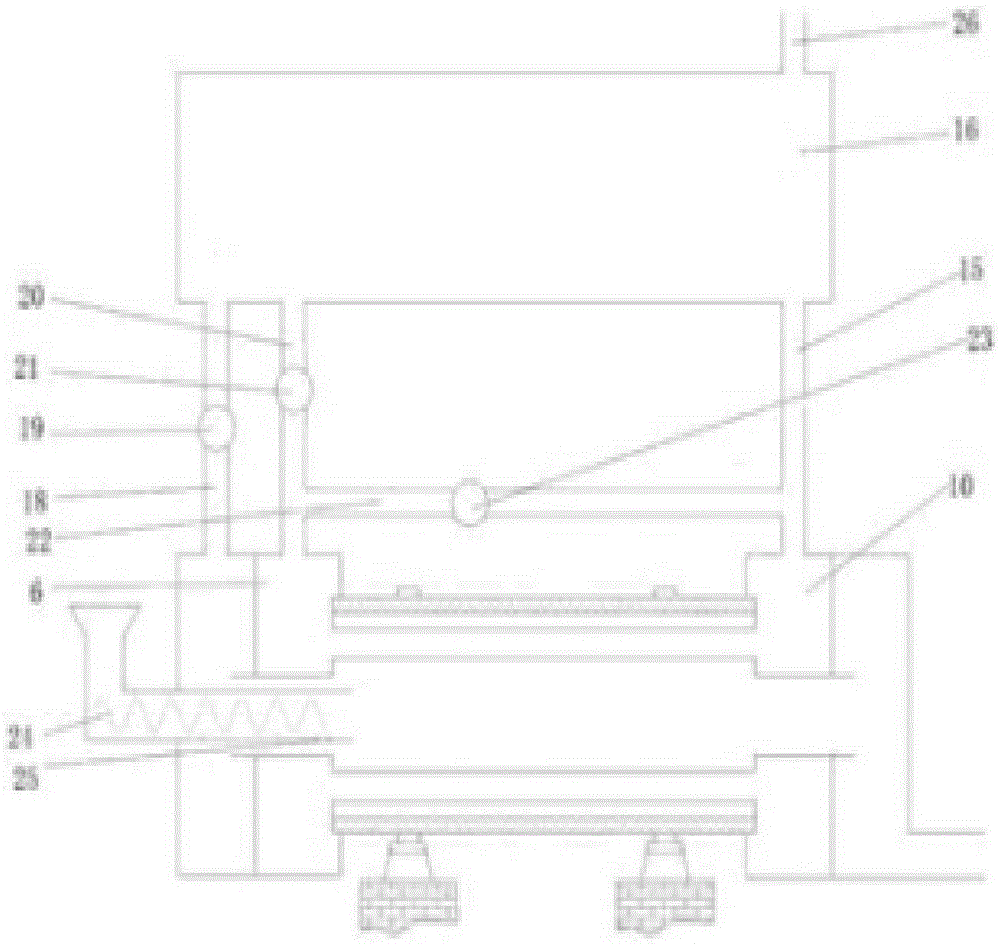

[0023] see figure 1 , is a schematic structural view of the rotary carbonization furnace according to an embodiment of the present invention; a rotary carbonization furnace includes a rotary furnace drum 3 and a feeder 1, and one end of the rotary furnace drum 3 is provided with the feeder 1 as a feed end, and the rotating The other end of the furnace drum 3 is the discharge end.

[0024] The rotary carbonization furnace also includes a combustion chamber 16, an air chamber 2 at the feed end, and an air chamber 14 at the discharge end. The chamber 2 is located at the feed end and is divided into a feed end gas chamber 4 and a feed end flue gas chamber 6 by a vertical feed end air chamber partition 5, the feed end gas chamber 4 and the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com