Method for preparing differentiated meta-aramid for filtering tiny dust

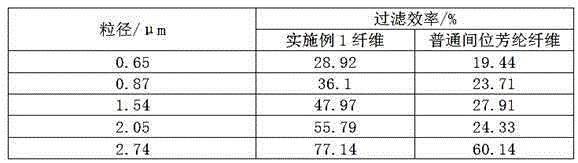

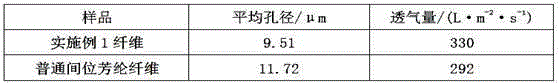

A differentiated, dusty technology that can be used in wet spinning, single-component polyester rayon, filament/thread forming, etc., and can solve problems such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Dissolve m-phenylenediamine in DMAc, add a certain amount of isophthaloyl chloride to react, and then remove the HCl generated by the reaction, and control the dynamic viscosity of the spinning solution to 520p, and defoam for later use;

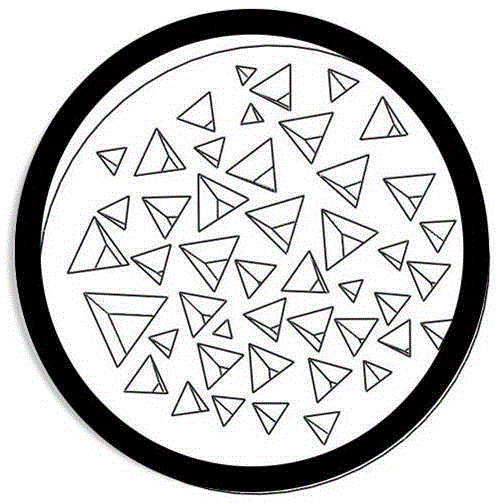

[0018] Extrude the prepared stock solution through a triangular special-shaped spinneret at a temperature of 25°C and contain 0.01% CaCl 2 , 56% DMAc aqueous solution in a coagulation bath for forming, and washing, drying, heat treatment, crimping, cutting to obtain differentiated meta-aramid staple fibers with a certain fineness range.

[0019] The triangular special-shaped spinneret has different pore diameters. There are 4 different pore sizes in total, and the pore size distribution gradually becomes larger from the inside to the outside; and the ratio of the number of holes from large to small is: 1:1:1.2:1.3.

Embodiment 2

[0021] Dissolve m-phenylenediamine in DMAc, add a certain amount of isophthaloyl chloride to react, then remove the HCl generated by the reaction, and control the dynamic viscosity of the spinning solution to 600p, and defoam for use;

[0022] Extrude the prepared stock solution through a triangular special-shaped spinneret, the entry temperature is 30°C, and contains 0.04% CaCl 2 , 65% DMAc aqueous solution in coagulation bath molding, and washing, drying, heat treatment, crimping, cutting, to obtain differential meta-aramid staple fibers with a certain fineness range.

[0023] The triangular special-shaped spinneret has different pore diameters. There are 5 different pore sizes in total, and the pore size distribution gradually becomes larger from the inside to the outside; and the ratio of the number of holes from large to small is: 1:1.1:1.2:1.3:1.4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com