Refining method and device for high-purity DMC (dimethyl carbonate)

A technology of dimethyl carbonate and a refining method, applied in the refining field of high-purity dimethyl carbonate, can solve the problems of large equipment investment, complicated process, poor quality of dimethyl carbonate, etc., and achieves a high degree of automation, a separation method and Simple process and good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

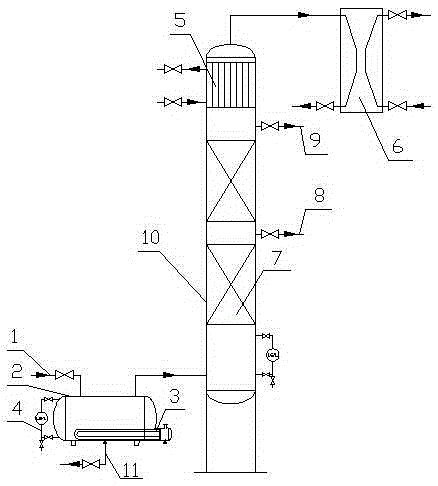

[0015] In this specific embodiment, the feed inlet of the raw material is selected on the horizontal kettle 2, and the packing layer 7 is divided into seven sections, and the height of each section of packing is 3 meters. Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0016] Step 1, feeding and steaming operation: continuously inject industrial-grade dimethyl carbonate with a purity of 99.5% into the horizontal kettle 2 with a material pump, and adjust the feeding when the liquid level gauge 4 of the horizontal kettle 2 shows 50cm The flow rate of port 1 is 790kg / h. At this time, open the steam valve of the built-in U-shaped tube bundle heat exchanger 3, add steam, control the steam pressure to 0.20Mpa, maintain total reflux in the tower and maintain the pressure in the tower at normal pressure . The specific method is to open the vent port of the secondary condensation gas-liquid separator 6 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com