A preparation method of near-field holography-ion beam etching for variable-pitch gratings

A technology of variable-pitch grating and ion beam etching, which is applied in the direction of diffraction grating, optics, optical elements, etc., can solve the problems of single groove profile, difficulty in preparation, and poor repeatability of grating line density, so as to simplify the optical path of holographic production and improve Accuracy, the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

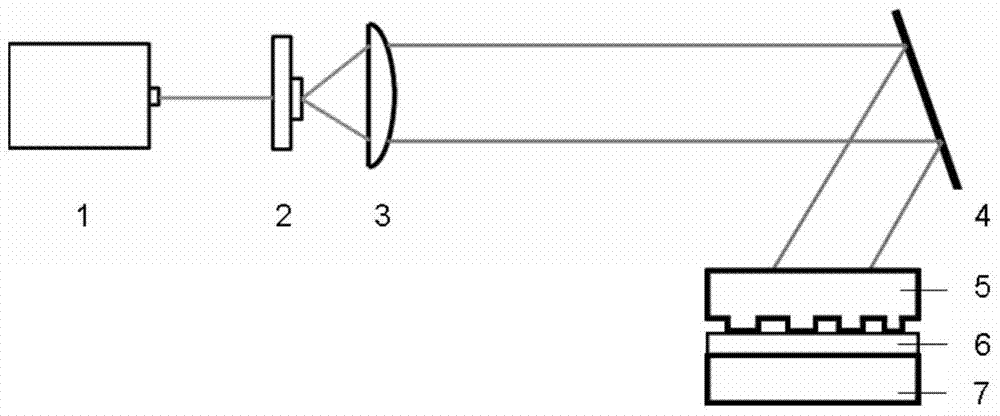

[0037] The present invention is a near-field holography-ion beam etching preparation method of a variable-pitch grating, the method comprising the following steps:

[0038] Step 1. According to the central period p of the variable-pitch grating to be fabricated 0 , determine the laser wavelength λ and incident angle i for near-field holographic exposure 0 , among the three satisfies:

[0039]

[0040] Using near-field holography can make variable-pitch grating period period and exposure laser wavelength λ and incident angle i 0 The following relationship should be satisfied:

[0041]

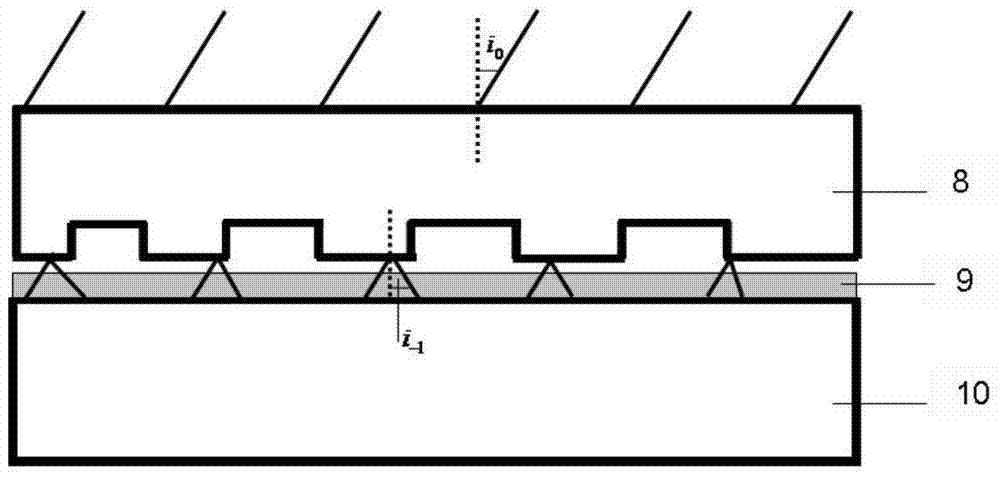

[0042] The purpose is that the incident laser light only has zero-order and negative-order diffraction after passing through the fused silica variable-pitch grating mask, and no other diffraction orders interfere with the generation of near-field holographic interference fringes;

[0043] Step 2, the design and manufacture of the fused silica variable pitch grating mask, the design meth...

Embodiment 1

[0057] Example 1: Central period p 0 A near-field holographic preparation method of a variable-pitch grating with a diameter of 416.6 nm (the central line density is 2400 lines / mm).

[0058] Step 1: A laser with a wavelength of 441.6nm is used as the exposure light source for near-field holography. Central period p 0 It is 416.6nm (the corresponding central line density is 2400 lines / mm). Calculate the incident angle i of near-field holographic exposure according to formula (1) 0 is 32°. According to the formula (2), the period variation range of the variable-pitch grating that can be reproduced is between 288nm-577nm. The period of the fused silica variable-pitch grating mask to be designed is between 333.2nm and 500nm.

[0059] Step 2: Design and fabrication of fused silica variable pitch grating mask

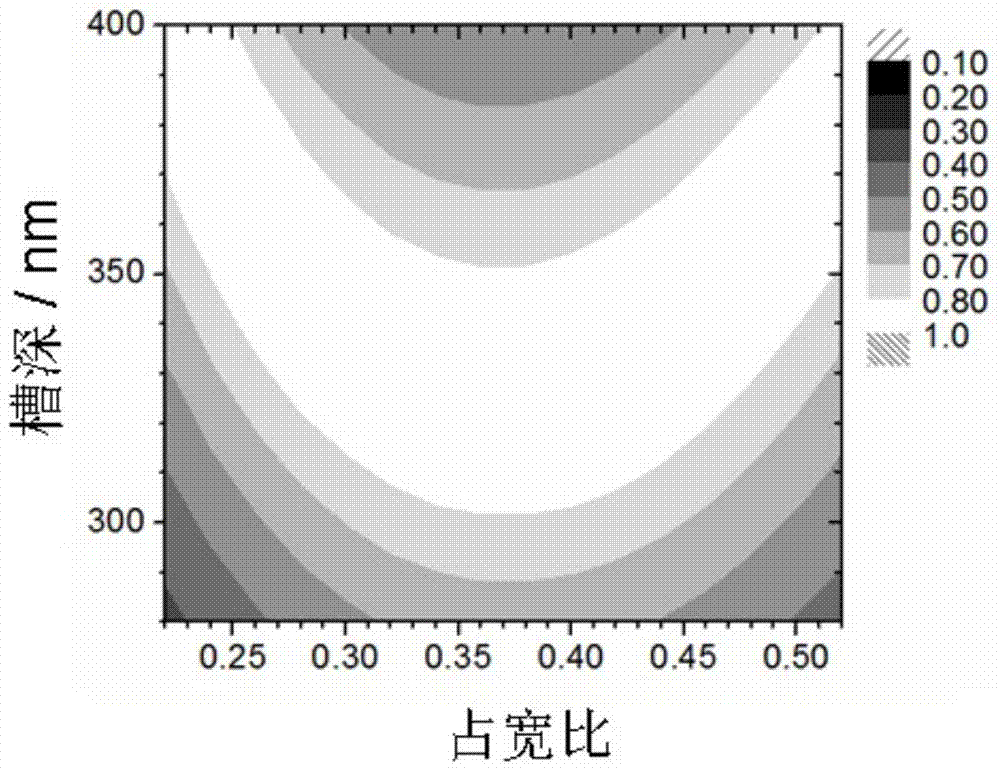

[0060] Design: range of groove profile (width ratio and groove depth) of a fused silica grating mask with a central period of 416.6nm;

[0061] Select the incident ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com