Electrochemical preparation method of MoS<2>/graphene composite counter electrode

A graphene composite and electrochemical technology, which is applied in the direction of electrolytic capacitors, circuits, capacitors, etc., can solve the problems of cumbersome preparation process, long reaction time, and additional steps, and achieve the effects of simplified steps, shortened reaction time, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

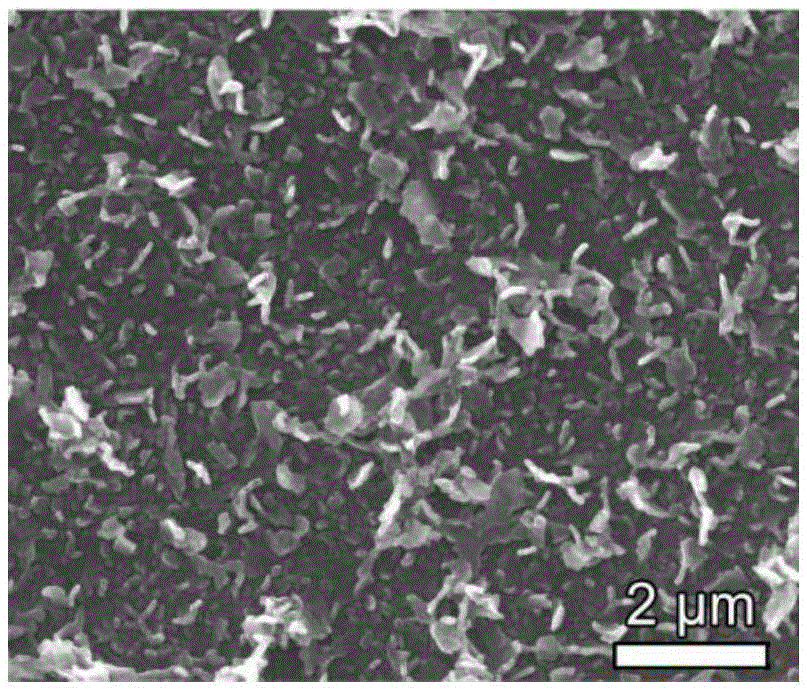

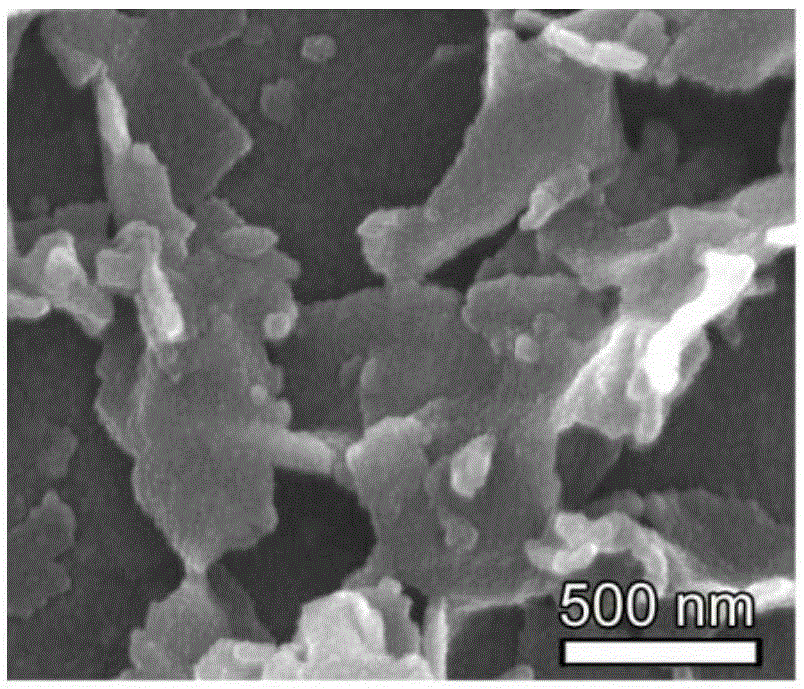

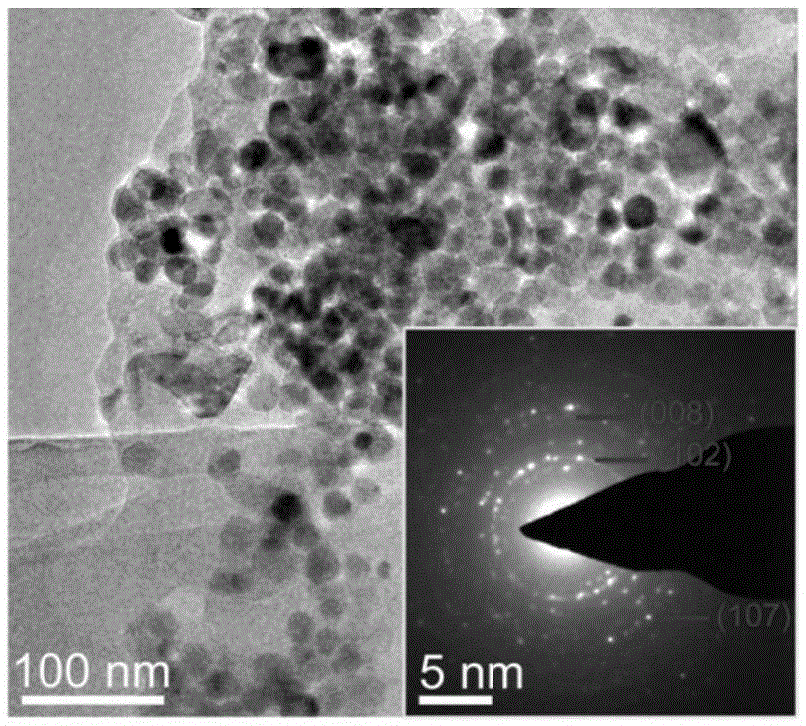

Image

Examples

Embodiment 1

[0022] (1) prepare graphene oxide / lithium perchlorate mixed aqueous solution, ultrasonically dissolve; wherein the concentration of graphene oxide is 2mg / mL, the concentration of lithium perchlorate is 0.02g / mL;

[0023] (2) Using an electrochemical workstation, the FTO glass substrate is used as the working electrode, the platinum electrode is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode. In the mixed aqueous solution of graphene oxide / lithium perchlorate, electrochemical deposition And reduce graphene oxide to FTO glass substrate to form graphene film; electrochemical deposition adopts constant potential deposition, the potential is -1.5V, and the deposition time is 2min;

[0024] (3) Prepare ammonium tetrathiomolybdate / potassium chloride mixed aqueous solution, and ultrasonically dissolve; wherein the concentration of ammonium tetrathiomolybdate is 0.2 mg / mL, and the concentration of potassium chloride is 5 mg / mL.

[...

Embodiment 2

[0028] (1) Prepare a mixed aqueous solution of graphene oxide / lithium perchlorate, and ultrasonically dissolve; wherein the concentration of graphene oxide is 3 mg / mL, and the concentration of lithium perchlorate is 0.05 g / mL.

[0029] (2) Using an electrochemical workstation, the FTO glass substrate is used as the working electrode, the platinum electrode is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode. In the mixed aqueous solution of graphene oxide / lithium perchlorate, electrochemical deposition And reduce graphene oxide to FTO glass substrate to form graphene film; electrochemical deposition adopts constant potential deposition, the potential is -1.0V, and the deposition time is 5min.

[0030] (3) Prepare ammonium tetrathiomolybdate / potassium chloride mixed aqueous solution, and ultrasonically dissolve; wherein the concentration of ammonium tetrathiomolybdate is 0.5 mg / mL, and the concentration of potassium chloride i...

Embodiment 3

[0035](1) Prepare a mixed aqueous solution of graphene oxide / lithium perchlorate, and ultrasonically dissolve; wherein the concentration of graphene oxide is 5 mg / mL, and the concentration of lithium perchlorate is 0.1 g / mL.

[0036] (2) Using an electrochemical workstation, the FTO glass substrate is used as the working electrode, the platinum electrode is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode. In the mixed aqueous solution of graphene oxide / lithium perchlorate, electrochemical deposition And reduce graphene oxide to FTO glass substrate to form graphene film; electrochemical deposition adopts constant potential deposition, the potential is -1.2V, and the deposition time is 2min.

[0037] (3) Prepare ammonium tetrathiomolybdate / potassium chloride mixed aqueous solution, and ultrasonically dissolve; wherein the concentration of ammonium tetrathiomolybdate is 0.8 mg / mL, and the concentration of potassium chloride is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com