Enrichment method for chambersite

A manganese boronite and enrichment technology is applied in the enrichment field of manganese boronite ore, which can solve problems such as unreported work on beneficiation and purification, and achieve the effects of improving grade, reducing grinding amount and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The original ore is the Chuanfangyu manganese boronite mine in Jixian County, Tianjin. The manganese boronite mine is a marine sedimentary type. The content of manganese boronite is 54.31%, the content of dolomite is 14.61%, and the content of quartz is 13.37%. stone, chlorite, illite, etc. The main valuable component in the ore is manganese boronite, the molecular formula is Mn 3 B 7 o 13 Cl, mainly semi-euhedral granular particles, mostly produced in the form of aggregates, and the aggregates are coarser in size and loosely combined, with clear contact boundaries with gangue mineral aggregates, and gangue minerals are mainly black-gray microcrystalline dolomite As well as black organic cement, gangue minerals have higher hardness. The chemical diversity analysis and X-ray diffraction analysis were carried out on the raw ore samples of the manganese boronite mine in Jixian County, Tianjin. The results are shown in Table 1. by B 2 o 3 and Cl content calculation an...

Embodiment 2

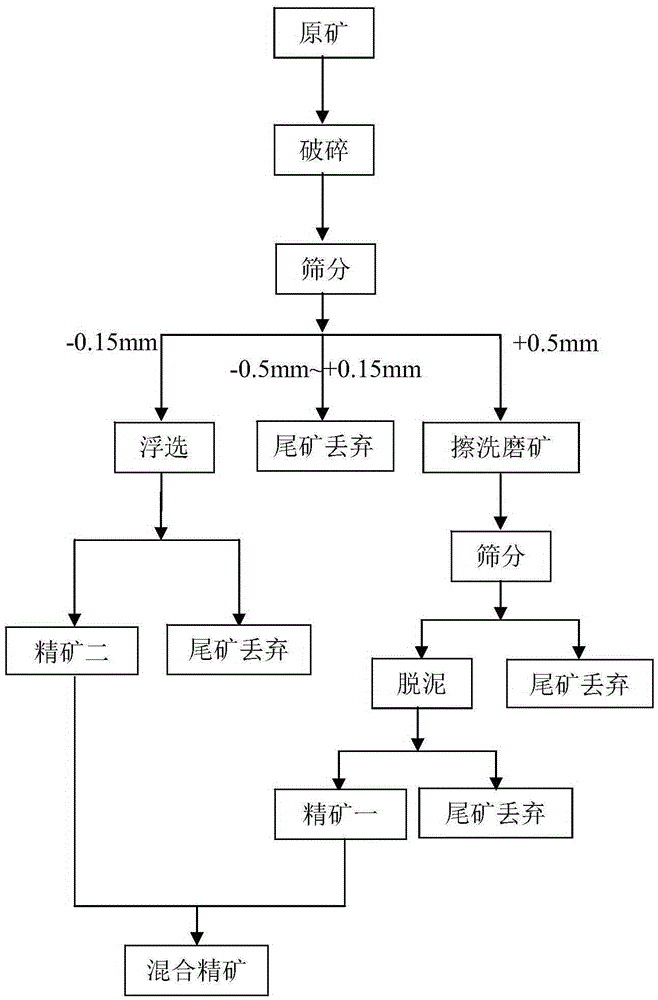

[0040] Step 1: Crushing the raw ore until the particle size is less than 2mm, and then sieving into three grades of +0.5mm, -0.5mm ~ +0.15mm, -0.15mm; the crushing adopts the second-stage crushing, and the first stage of the second-stage crushing The jaw crusher is used for crushing, and the long cavity crusher is used for the second stage of crushing.

[0041] Step 2: The -0.5mm~+0.15mm particle grade product obtained in Step 1 is directly thrown as tailings;

[0042] Step 3: Slurry the +0.5mm particle size product obtained in step 1 to obtain pulp 1, scrub and grind the pulp 1, and then sieve to remove the +0.15mm particle size before desliming. get concentrate one;

[0043] In the step 3, the pulp concentration of pulp one is 70%, the scrubbing and grinding equipment is a vertical agitating mill, the stirring speed is 200r / min, the scrubbing time of the agitating mill is 10min, and the filling rate of the agitating mill scrubbing medium is 0%.

[0044] The desliming descr...

Embodiment 3

[0052] Step 1: Crushing the raw ore until the particle size is less than 2mm, and then sieving into three grades of +0.5mm, -0.5mm ~ +0.15mm, -0.15mm; the crushing adopts the second-stage crushing, and the first stage of the second-stage crushing The jaw crusher is used for crushing, and the long cavity crusher is used for the second stage of crushing.

[0053] Step 2: The -0.5mm~+0.15mm particle grade product obtained in Step 1 is directly thrown as tailings;

[0054] Step 3: Slurry the +0.5mm particle size product obtained in step 1 to obtain pulp 1, scrub and grind the pulp 1, and then sieve to remove the +0.15mm particle size before desliming. Concentrate 1 is obtained; the pulp concentration of pulp 1 is 60%, the scrubbing and grinding equipment is a vertical agitating mill, the stirring speed is 100r / min, the scrubbing time of the agitating mill is 30min, and the filling rate of the agitating mill scrubbing medium is 0%.

[0055] Desliming refers to the removal of -0.04...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com