Process and device for removing ash of high-temperature electrostatic precipitator by sectional spraying coupling with water film flushing

A technology of high-temperature electrostatic precipitator and dust removal device, which is applied in electrostatic separation, electrode cleaning, etc., can solve problems such as difficulty in dust removal, achieve broad market application prospects, and avoid poor effect of vibrating dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

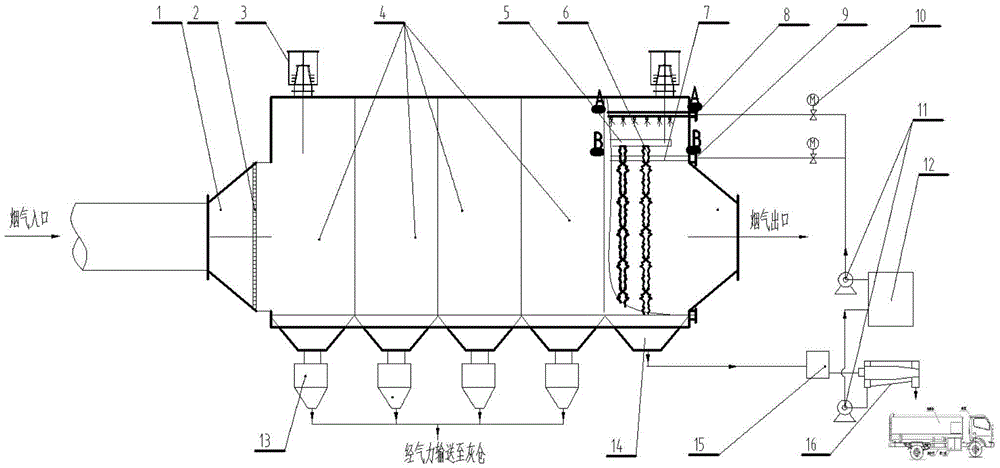

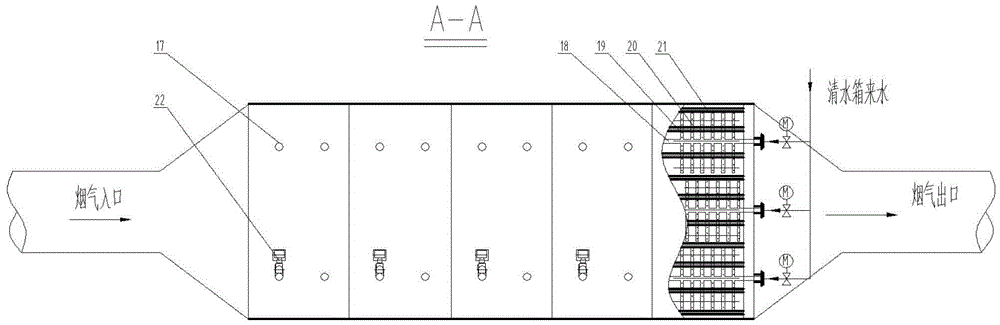

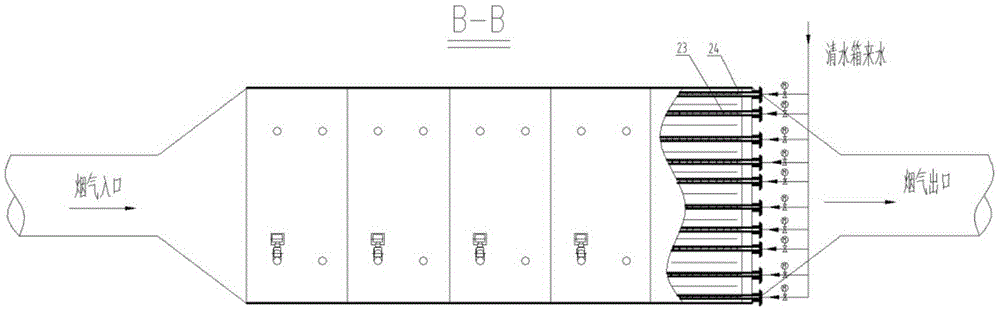

[0030] Combine below figure 1 , figure 2 , image 3 A best specific embodiment of the present invention is given.

[0031] Such as figure 1 , 2As shown in 3, the high-temperature electrostatic precipitator partition spray flushing coupling continuous water film high-efficiency dust removal device is composed of the dust collector shell, cathode, anode, spray flushing system, water film flushing system, high-voltage power supply, insulator, etc., and the overall connection The relationship is as follows:

[0032] One end of the housing is the smoke inlet, and the opposite end is the smoke outlet. The bottom of the housing is provided with a plurality of ash hoppers communicating with the inside of the housing. The inside of the housing is divided into multiple The electric field of the dust collector, and along the direction of flue gas flow, in the shell of the final electric field, there are spray flushing devices, water film flushing devices, anode plates and cathode s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com