Cold rolling method for improving structure properties of ferritic stainless steel plate strips and analysis method thereof

A stainless steel plate, microstructure and performance technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of low microstructure and performance of stainless steel strips, reduce the cost of industrial experiments, reduce the number of simulations, and improve test accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

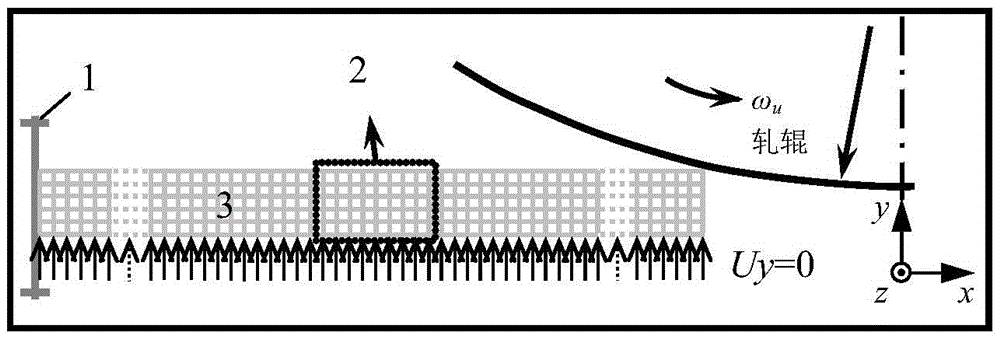

[0052] An analysis method of a cold rolling method for improving the microstructure and properties of ferritic stainless steel strips, comprising the following steps:

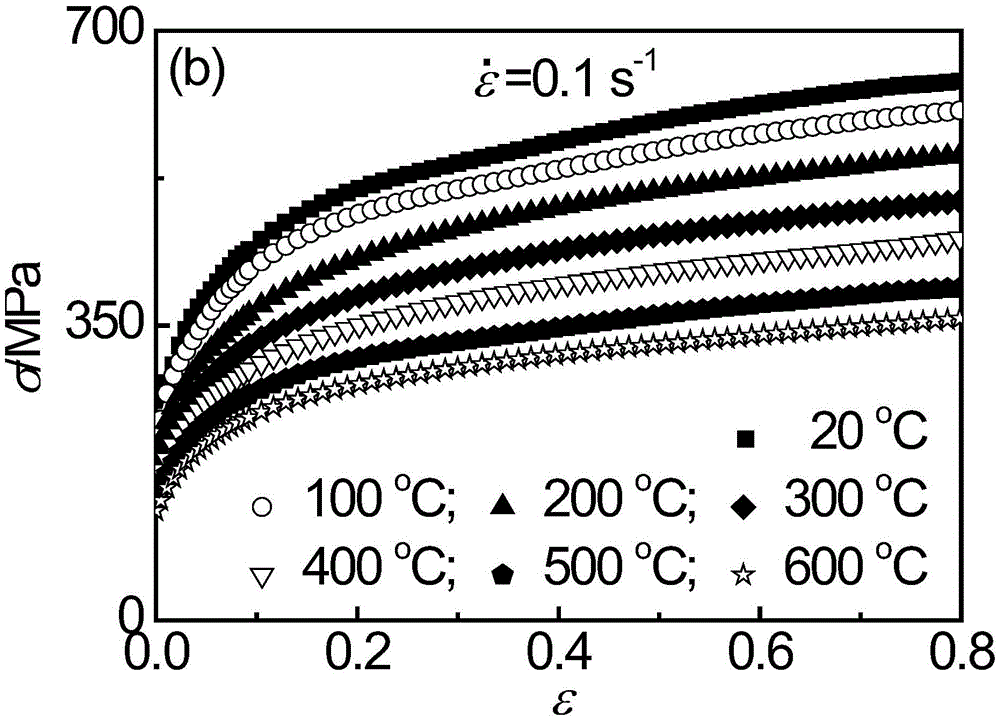

[0053] 1) The stress and strain data of the ferritic stainless steel to be cold-rolled in the temperature range from room temperature to 300 °C were collected through the uniaxial compression experiment of the cylinder, and made as follows: figure 1 The stress-strain curve shown, considering that ferritic stainless steel does not undergo dynamic recrystallization in this temperature range, the strain rate of the experiment is taken as 0.1s -1 , in order to prevent damage to the hammer head used in the thermal simulation testing machine, the hammer head was replaced with a nickel-based superalloy;

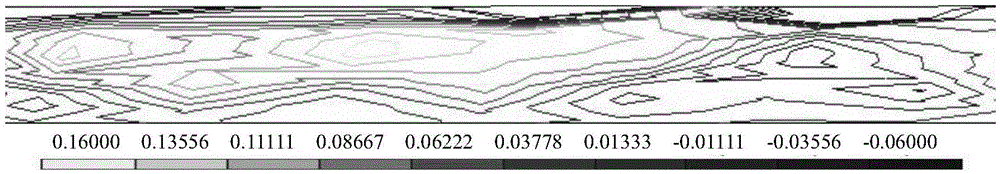

[0054] 2) Determine the deformation resistance model of ferritic stainless steel according to the temperature, stress and strain data collected in step 1), the specific steps are:

[0055] a) building a database wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com