Grinding state detecting and controlling method and device based on sound emission

A grinding state, measurement and control method technology, applied in the direction of grinding machine parts, grinding/polishing equipment, workpiece feed movement control, etc., can solve the problem of high sales price, high use cost and grinding state detection of AEMS system Problems such as low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

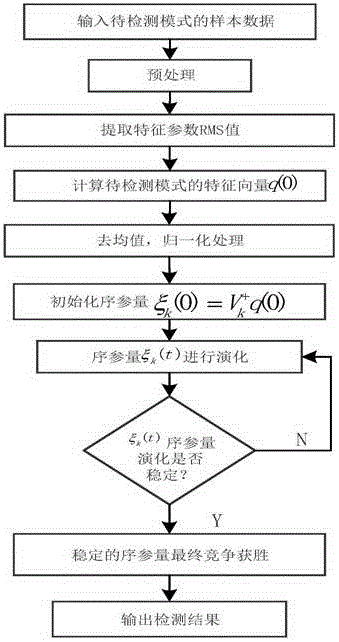

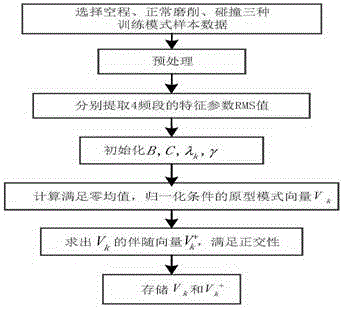

Method used

Image

Examples

specific Embodiment

[0138] In the grinding process, the grinding wheel or the workpiece is completed by segmental grinding, that is, the processing of a single workpiece is completed. The numerical control system controls the grinding wheel to have multiple feeding and retracting. Slow feed is used to shorten the empty travel time to achieve the purpose of eliminating empty travel. The system detects abnormal conditions during the grinding process at the same time to prevent equipment damage and achieve the purpose of anti-collision.

[0139] The complete working process of the grinder is as follows:

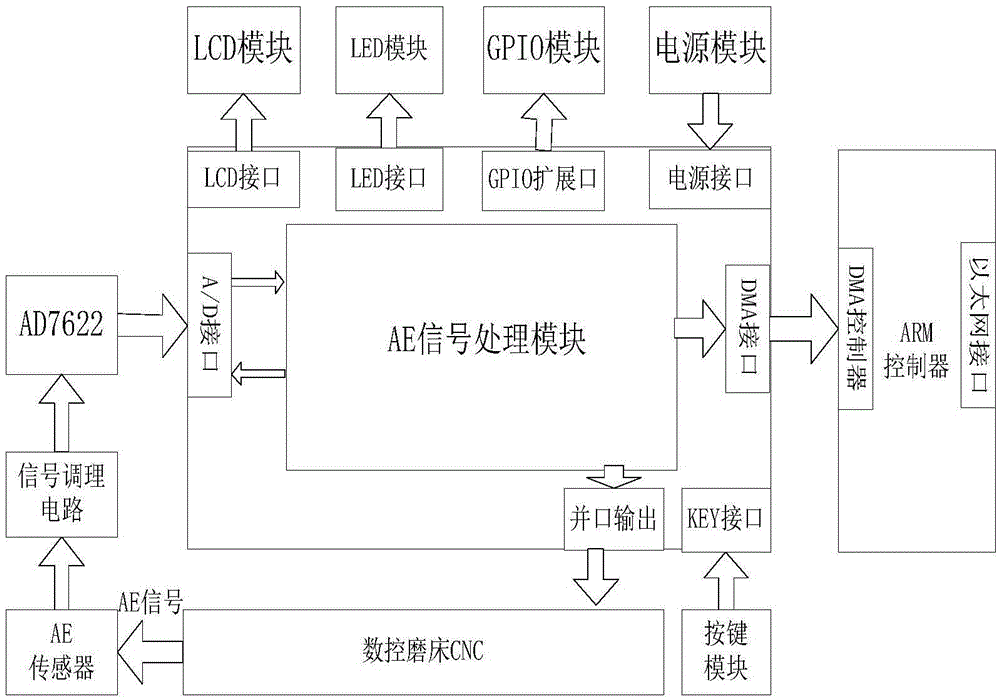

[0140] (1) Acoustic emission signal acquisition

[0141]Install the acoustic emission AE sensor (SB-4200 from American SCHMITT company, the resonant frequency is 300Khz, the frequency range is 50Khz-950Khz) to the machine casting or other hard machine devices. The installation point must be flat and can prevent chips, etc. influence of external substances. After the signal conditioning circuit am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com