Cyanide-free gold-plated electroplating liquid and method for electroplating ceramic surface with dense gold thin film through pulses

A cyanide-free gold-plating and ceramic surface technology, which is applied in the field of ceramic surface metallization, can solve the problems of poor bonding between the gold-plated layer on the ceramic surface and the substrate, poor stability of the cyanide-free gold-plated electroplating solution, and difficult control of the surface brightness of the coating. Good binding force and wear resistance, high reproducibility, fast and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific embodiments. The description of specific embodiments is only an example in nature, and is not intended to limit the disclosed content of the present invention and its application or use.

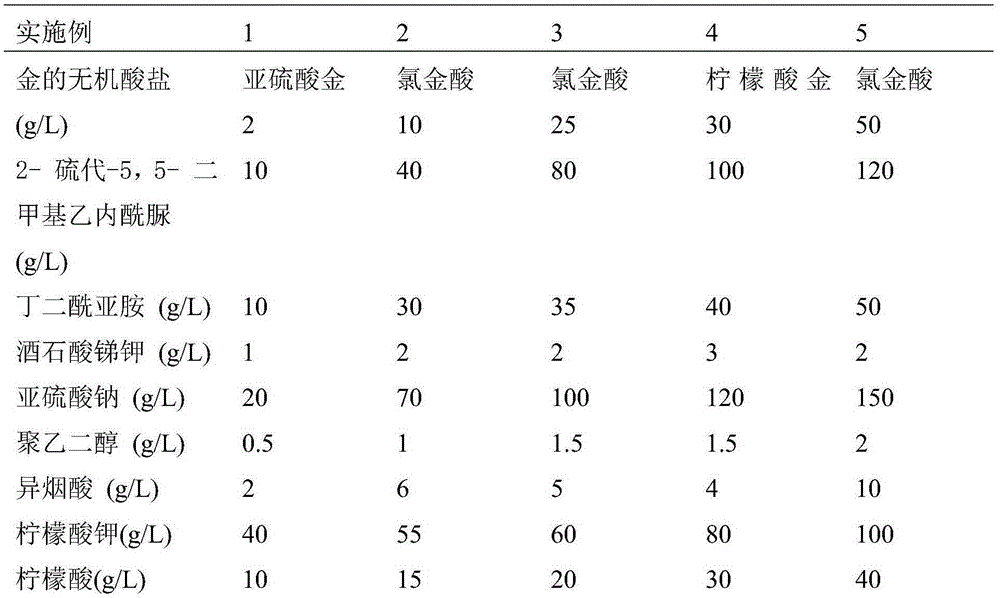

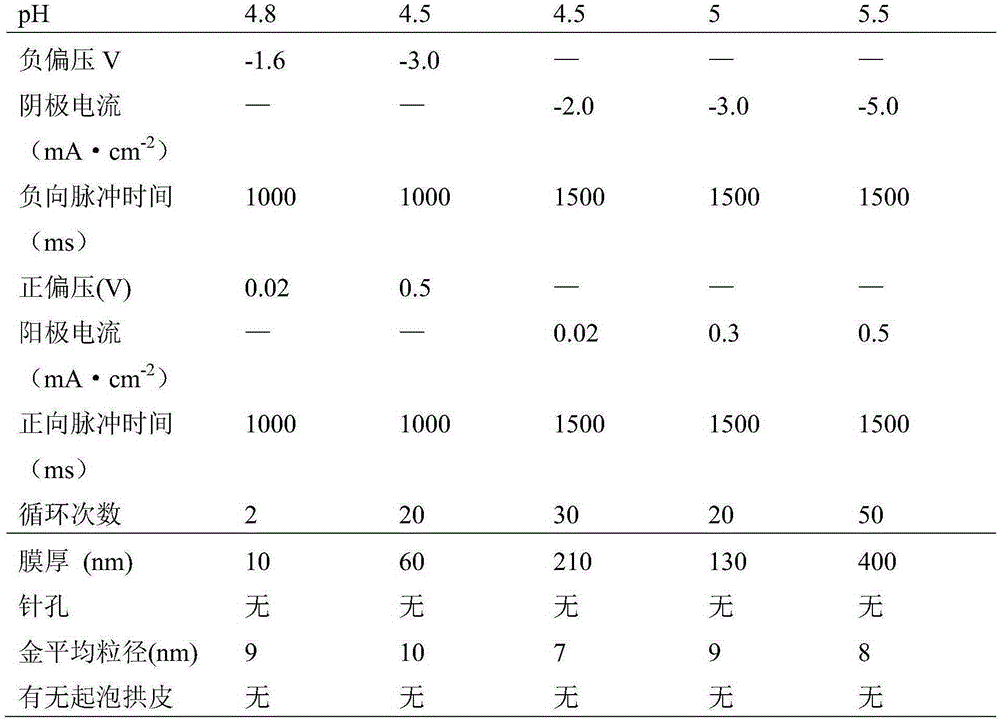

[0020] 1) Preparation of gold-plating electroplating solution: first, it is prepared to contain 2-thio-5,5-dimethylhydantoin 10-120g / L, succinimide 10-50g / L, and potassium antimony tartrate 1 ~3g / L, polyethylene glycol 0.5~2g / L, sodium sulfite 20~150g / L, isonicotinic acid 2~10g / L and potassium citrate 40~100g / L aqueous solution, add mineral acid salt of gold, the The concentration of the mineral acid salt of gold is 2-50g / L. Finally, 10-40g / L of citric acid is used to adjust the pH at 5±0.5, and the temperature of the cyanide-free gold plating solution is kept at 50±3°C.

[0021] 2) Pretreatment of the ceramic surface: immerse the ceramic in a 1:1 (v:v) mixed solution of acetone and dichloromethane, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com