Camouflage EVA (Ethylene Vinyl Acetate) long running shoe insole and preparation method thereof

A long-distance running and camouflage technology, which is applied in soles, footwear, clothing, etc., can solve the problems of poor product stability, closed pores easily become connected pores, poor crystallization performance, etc., to reduce sports injuries, mature production technology, The effect of a small damping factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

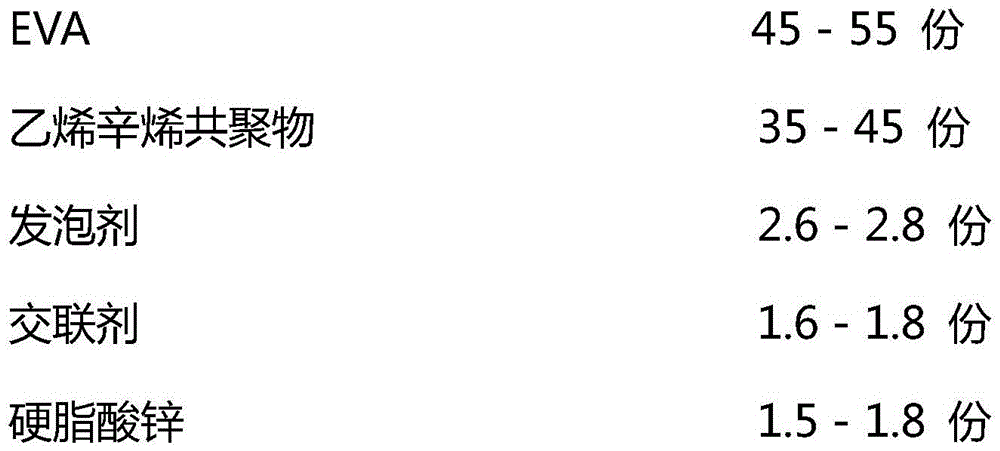

[0029] In the present embodiment, the midsole of the camouflage EVA long-distance running shoes is composed of the following components by weight:

[0030]

[0031] The preparation method at the end of described camouflage pattern EVA long-distance running shoes, comprises the steps:

[0032] Step 1: First mix the above raw materials (except pigments) for banburying, adjust the banburying temperature to 97°C, keep it for 6 minutes, then turn over the material twice, continue banburying and heat up, the output temperature is 107°C, banburying is over Afterwards, kneading and granulation are carried out to obtain natural color EVA rice;

[0033] Step 2: Stir the natural color EVA material rice and phthalocyanine green 311 in the mixing tank evenly to obtain green material rice; mix the natural color EVA material rice and permanent yellow 1148 in the mixing tank to obtain yellow material rice; Stir the permanent red BH-5RK evenly in the mixing tank to get red rice; then mix t...

Embodiment 2

[0037] In the present embodiment, the preparation method at the end of a kind of camouflage color EVA long-distance running shoes is the same as that in Example 1, except that in the proportioning of raw materials:

[0038] EVA7240M45 parts, ethylene octene copolymer 844030 parts, ethylene octene copolymer 848015 parts, talcum powder 8 parts, permanent violet HR-2560.2 parts, phthalocyanine blue 1560.2 parts, permanent orange TR1390.2 parts.

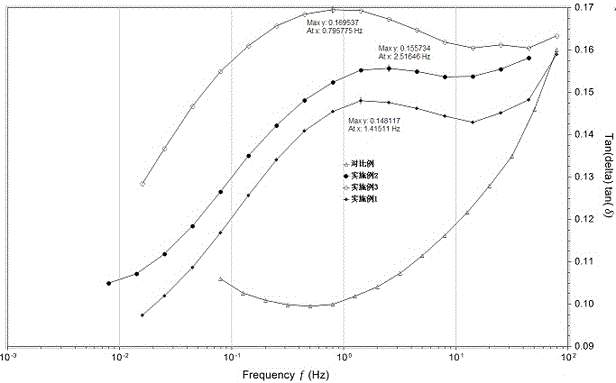

[0039] The camouflage color EVA long-distance running shoes mid-sole that above-mentioned preparation obtains, density 0.175g / cm 3 , hardness 59, dimensional shrinkage 0.2%, rebound rate 34%, compression deformation rate 54%, tear strength 10.1N / mm, tensile strength 2.8MPa, Tanδ peak value is 0.155, and the corresponding frequency of Tanδ peak value is 2.51Hz.

Embodiment 3

[0041] In the present embodiment, the preparation method at the end of a kind of camouflage color EVA long-distance running shoes is the same as that in Example 1, except that in the proportioning of raw materials:

[0042] 35 parts of EVAV4110J, 20 parts of EVA55020 parts, 845235 parts of ethylene octene copolymer, 1.8 parts of crosslinking agent BIBP, 1.8 parts of zinc stearate, 12 parts of talcum powder.

[0043] The camouflage color EVA long-distance running shoes midsole that above-mentioned preparation obtains, density 0.152g / cm 3 , hardness 49, dimensional shrinkage 1.0%, rebound rate 32%, compression deformation rate 63%, tear strength 6.4N / mm, tensile strength 2.1MPa, Tanδ peak value is 0.169, and the corresponding frequency of Tanδ peak value is 0.79Hz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com