Humidity-heat-resistant long-acting anticorrosion coating

A long-term anti-corrosion and heat-and-humidity-resistant technology, applied in the field of coatings, can solve problems such as poor alkali resistance, achieve the effects of improving strength, convenient construction, and improving coating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

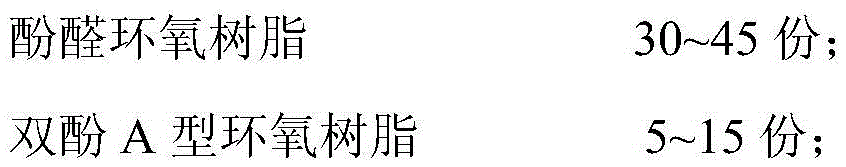

[0023] The coating of this embodiment is composed of the following components by weight:

[0024]

[0025] Among the components in this embodiment, the coupling agent is γ-aminopropyltriethoxysilane, the defoaming agent is an organosilicon defoaming agent, and the weight ratio of xylene and n-butanol in the solvent is 2:1.

Embodiment 2

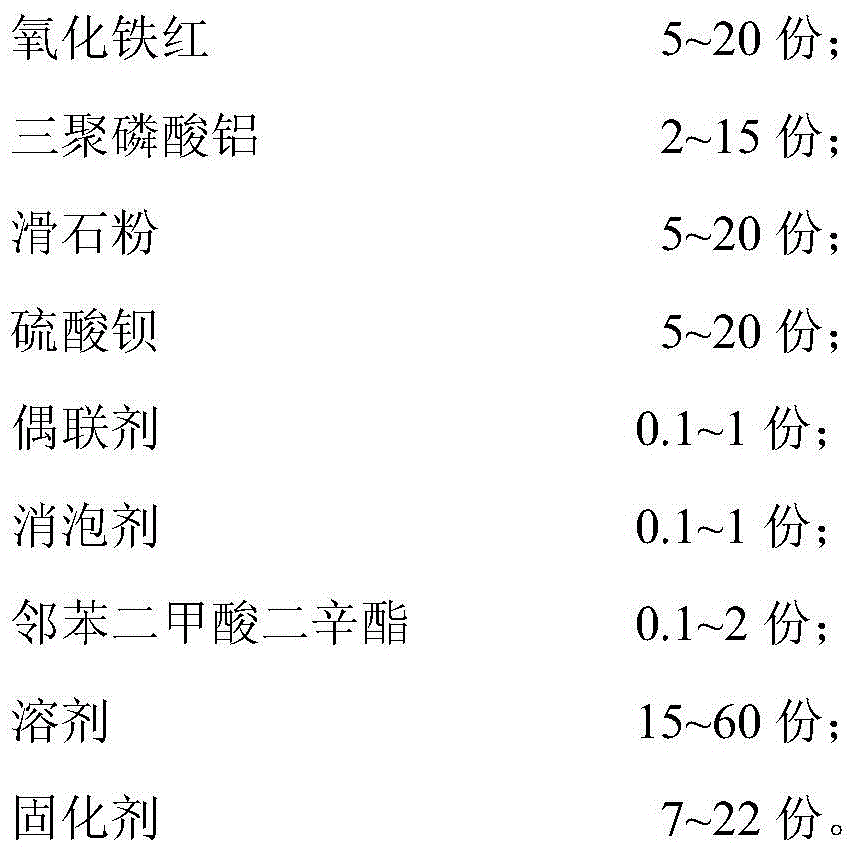

[0027] The coating of this embodiment is composed of the following components by weight:

[0028]

[0029] Among the components in this embodiment, the coupling agent is γ-aminopropyltriethoxysilane, the defoaming agent is an acrylate defoaming agent, and the weight ratio of xylene and n-butanol in the solvent is 3:1.

Embodiment 3

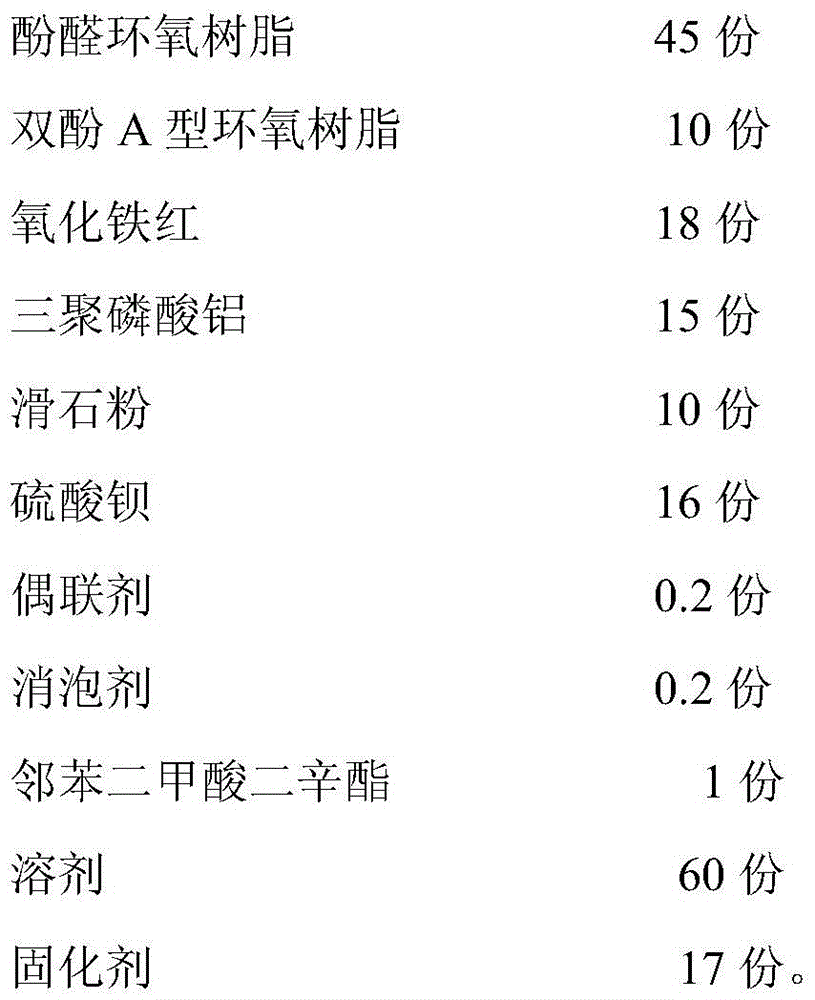

[0031] The coating of this embodiment is composed of the following components by weight:

[0032]

[0033] Among the components in this example, the coupling agent is γ-(2,3-glycidoxy)propyltrimethoxysilane, the defoamer is an acrylate defoamer, and the weight of xylene and n-butanol in the solvent The ratio is 5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com