Perovskite KTaO3 potassium ion battery negative electrode material synthesized by electric field control and crystallization selection and preparation method thereof

A technology of selective crystallization and battery negative electrode, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as slow migration of potassium ions, material lattice transformation, and broken electrode material particles, so as to reduce electron migration resistance and improve Movement ability, effect of reducing grain boundary resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

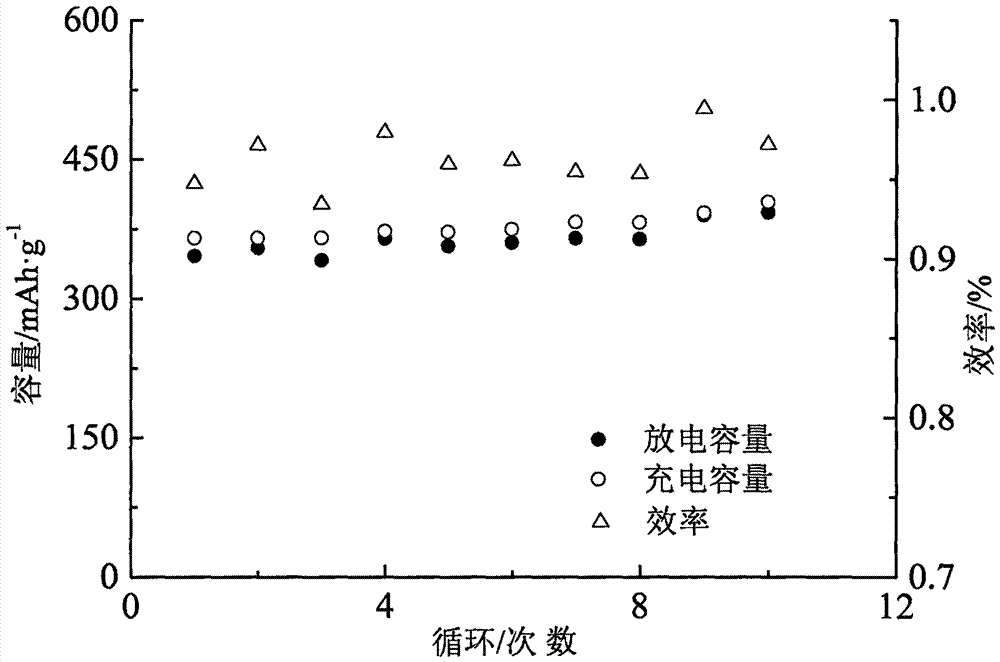

Embodiment 1

[0021]Embodiment 1: Potassium nitrate and tantalum hydroxide are put into the ball mill with the ratio of 1: 1 of the amount of substance, the mass ratio of the ball mill and the material is 20: 1, and ball milled at a speed of 400 rpm for 20 hours. The ball-milled material is heated up to 900°C at a rate of 10°C / min in a tube furnace, and then a DC voltage of 900V is applied to both ends of the tube furnace. Cool the furnace to 30°C; grind the cooled material in a mortar for 12 minutes, and immerse it in a saturated solution of lithium metaborate at a constant temperature of 30°C under constant stirring at a speed of 1200 rpm with a polytetrafluoroethylene stirring paddle. The mass ratio of the mass to the immersed cooled material is 10:1. After continuous stirring for 9 minutes, the constant temperature was lowered to 22°C and continued to stir for 15 minutes, then filtered and dried in a drying oven at 160°C for 10 hours . Then the dried material was heated to 550°C at a r...

Embodiment 2

[0022] Embodiment 2: Potassium nitrate and tantalum hydroxide are put into the ball mill with the ratio of 1:1 of the amount of substance, the mass ratio of the ball mill and the material is 20:1, and ball milled at a speed of 400 rpm for 15 hours. The ball-milled material is heated to 900°C at a rate of 8°C / min in a tube furnace, and then a DC voltage of 900V is applied to both ends of the tube furnace. Cool the furnace to 30°C; grind the cooled material in a mortar for 12 minutes, and immerse it in a saturated solution of lithium metaborate at a constant temperature of 30°C under constant stirring at a speed of 1000 rpm with a polytetrafluoroethylene stirring paddle. The mass ratio of the mass to the immersed cooled material is 10:1. After stirring continuously for 7 minutes, reduce the temperature of the constant temperature to 20°C and continue stirring for 10 minutes, then filter and dry in a drying oven at 140°C for 8 hours . Then the dried material was heated to 500°C ...

Embodiment 3

[0023] Embodiment 3: Potassium nitrate and tantalum hydroxide are put into the ball mill with the ratio of 1:1 of the amount of substance, the mass ratio of the ball mill and the material is 20:1, and ball milled at a speed of 200 rpm for 10 hours. The ball-milled material is heated to 800°C at a rate of 2°C / min in a tube furnace, and then a DC voltage of 600V is applied to both ends of the tube furnace. Cool the furnace to 30°C; grind the cooled material in a mortar for 6 minutes, and immerse it in a saturated solution of lithium metaborate at a constant temperature of 30°C under constant stirring at a speed of 900 rpm with a polytetrafluoroethylene stirring paddle. The mass ratio of the mass to the immersed cooled material is 10:1. After stirring for 5 minutes, reduce the constant temperature to 18°C and continue stirring for 5 minutes, then filter and dry in a drying oven at 120°C for 5 hours . Then the dried material was heated to 450°C at a rate of 3°C / min in a tube fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com