Super-oleophobic coating and preparation method thereof

A super oleophobic and coating technology, which is applied in the direction of coating, can solve the problems of human body and environmental impact, and achieve the effect of excellent oleophobic performance, simple operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] By magnetic stirring and ultrasonic dispersion, 0.1 g of fumed silica nanoparticles (with a specific surface area of 300m 2 / g) dispersed in 10g TrisHCl buffer solution to prepare a uniform and stable dispersion, adding dopamine hydrochloride to form a composite dispersion with a dopamine hydrochloride concentration of 0.5 mg / mL. The above dispersion liquid was magnetically stirred under the condition of being connected to the atmosphere, and reacted for 24 hours to polymerize dopamine into polydopamine.

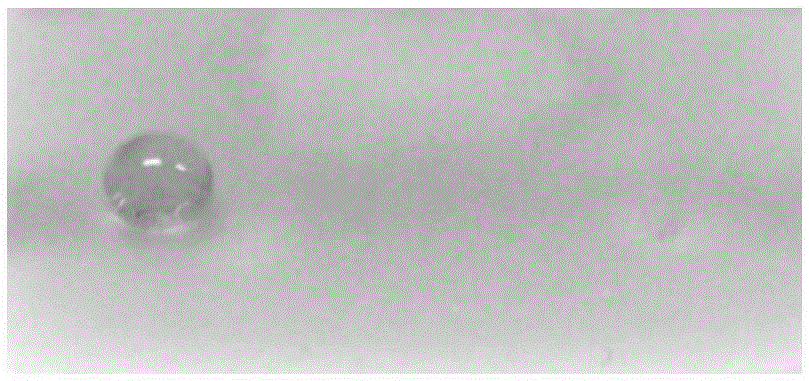

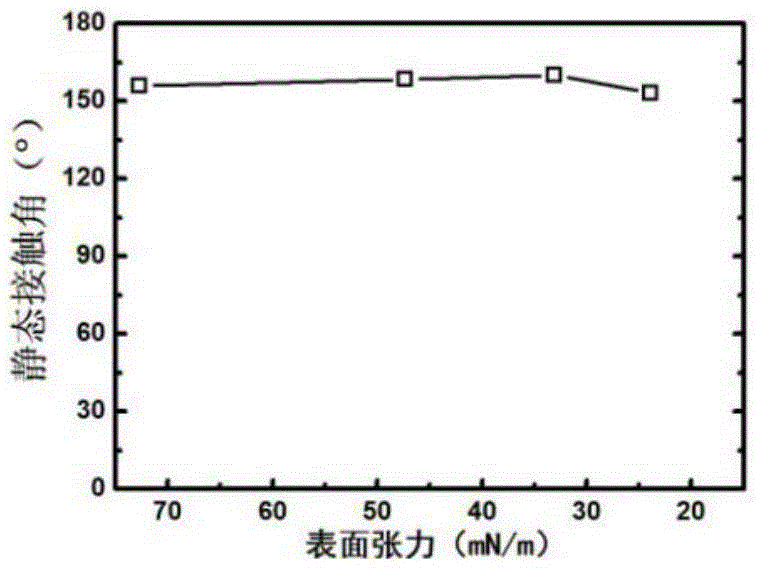

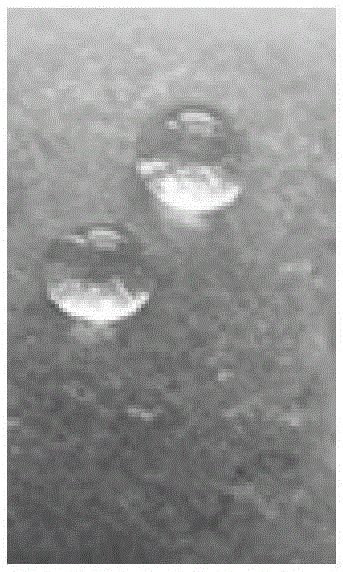

[0060] According to 60μL / cm 2 The dosage is to apply the dispersion liquid on the glass surface, freeze it at -80°C and freeze-dry it. Afterwards, the coating was subjected to two-step CVD treatment: the first step, CVD treatment with 1 mL aminopropyltriethoxysilane at 25 °C for 24 hours; the second step, 300 μL 1H, 1H, 2H, 2H-all at 25 °C Fluorodecyltriethoxysilane was subjected to CVD treatment for 24 hours. Finally, the superoleophobic coating ( figure 1 ). ...

Embodiment 2

[0063] By magnetic stirring and ultrasonic dispersion, 0.3g fumed silica nanoparticles (specific surface area is 100m 2 / g) dispersed in 10g TrisHCl buffer solution to prepare a uniform and stable dispersion, adding dopamine hydrochloride to form a composite dispersion with a dopamine hydrochloride concentration of 1mg / mL. The above dispersion liquid was magnetically stirred under the condition of being connected to the atmosphere, and reacted for 24 hours to polymerize dopamine into polydopamine.

[0064] According to 60μL / cm 2 The dosage is to apply the dispersion liquid on the glass surface, freeze it at -80°C and freeze-dry it. Afterwards, the coating was subjected to two-step CVD treatment: the first step, CVD treatment with 1 mL aminopropyltriethoxysilane at 25 °C for 24 hours; the second step, 300 μL 1H, 1H, 2H, 2H-all at 25 °C Fluorodecyltriethoxysilane was subjected to CVD treatment for 24 hours. Finally, a super-oleophobic coating is obtained.

[0065] The value ...

Embodiment 3

[0067] By magnetic stirring and ultrasonic dispersion, 0.3g fumed silica nanoparticles (specific surface area is 200m 2 / g) dispersed in 10g TrisHCl buffer solution to prepare a uniform and stable dispersion, adding dopamine hydrochloride to form a composite dispersion with a dopamine hydrochloride concentration of 0.5 mg / mL. The above dispersion liquid was magnetically stirred under the condition of being connected to the atmosphere, and reacted for 24 hours to polymerize dopamine into polydopamine.

[0068] According to 20μL / cm 2 The dosage is to apply the dispersion on the glass surface, freeze it at -40°C and freeze-dry it. Afterwards, the coating was subjected to two-step CVD treatment: the first step, CVD treatment with 1 mL aminopropyltriethoxysilane at 40 °C for 24 hours; the second step, 300 μL 1H, 1H, 2H, 2H-all Fluorodecyltriethoxysilane was subjected to CVD treatment for 24 hours. Finally, a super-oleophobic coating is obtained.

[0069] The value of the contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com