A method for extracting rose essential oil by ultra-high pressure combined with steam distillation

A technology of steam distillation and rose essential oil, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of increased thermal decomposition loss impurity content, increased methyl eugenol content, poor wall breaking effect, etc., and achieves an increased degree of destruction Larger, higher yield and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

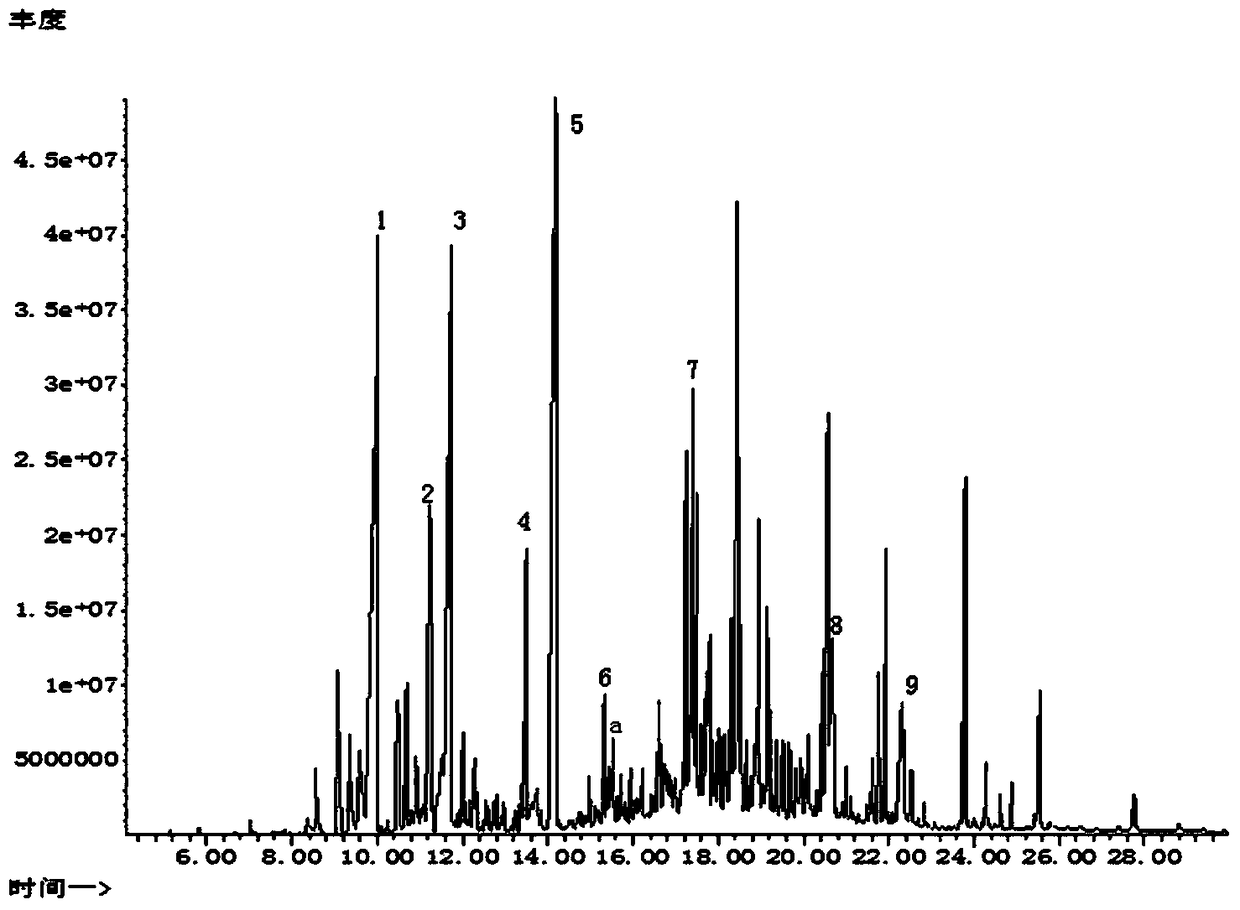

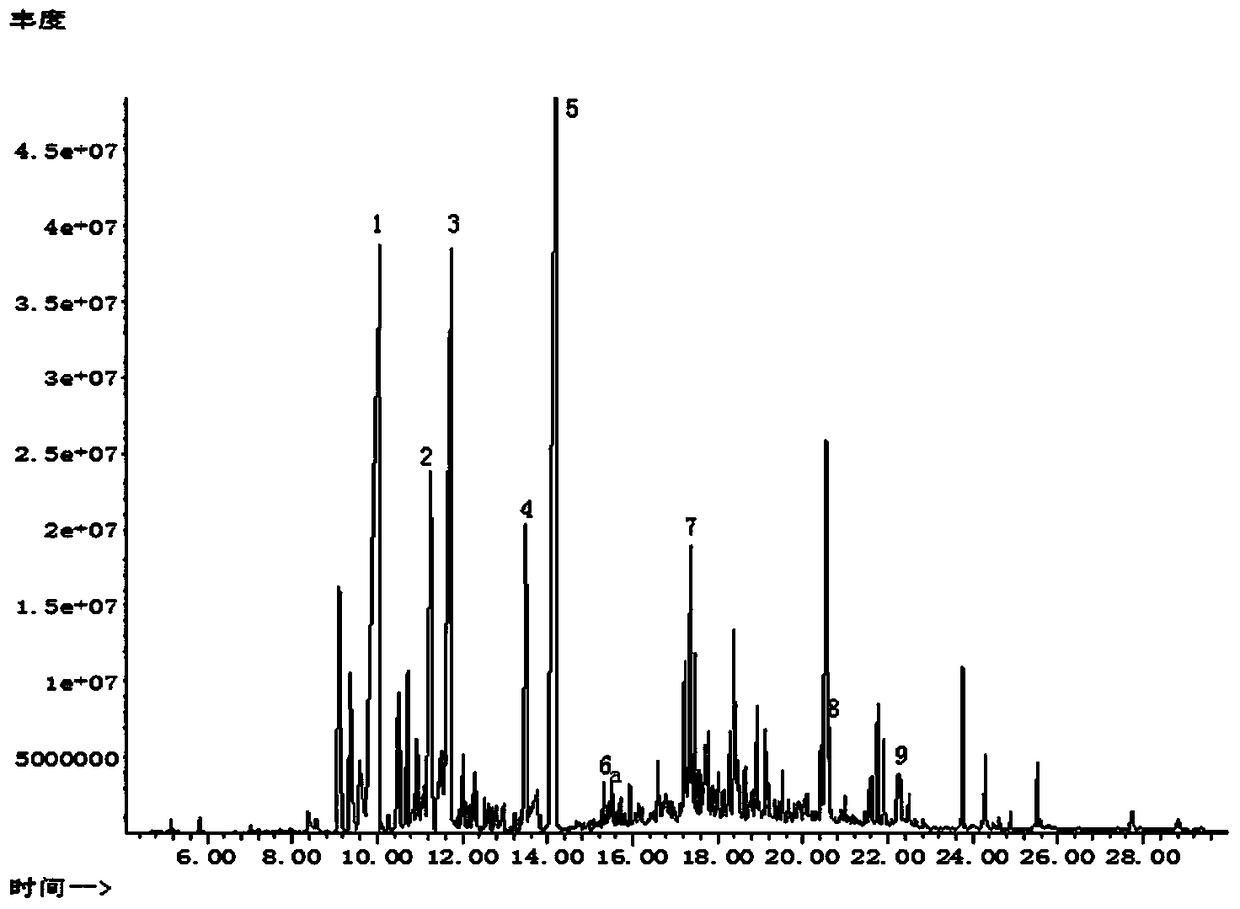

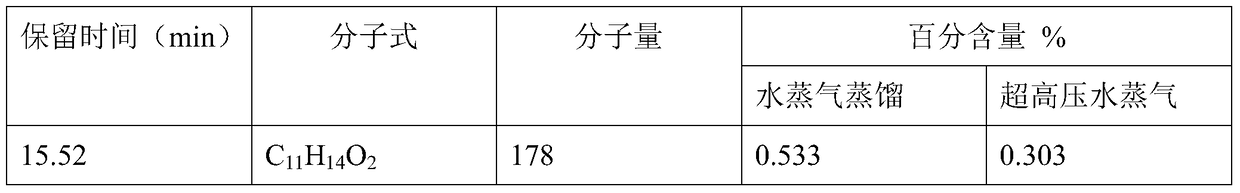

Method used

Image

Examples

Embodiment 1

[0036]For fresh Pingyin roses, add a citric acid aqueous solution with a mass concentration of 0.5% at a ratio of material to liquid ratio of 1.0:2.0 (by weight), mix evenly, seal a polyethylene retort bag at the level of the liquid surface, and place under pressure Ultrasonic extraction kettle; pressure 500MPa, holding time 6min, temperature 25°C. After the end of the ultra-high pressure, put the material liquid in the sealed bag into the distillation bottle for steam distillation, and use deionized water as the steam source; control the heating temperature to 102°C to ensure the continuous and stable output of water vapor; set the distillation bottle The heat preservation temperature is 99°C to control the evaporation rate in the distillation bottle; the cooling water circulation device is used to control the flow rate and temperature of the condensed water to control the condensation rate; the distillation time is 2h; the first drop of distillate flowing out from the condens...

Embodiment 2

[0045] For fresh Pingyin roses, add a citric acid aqueous solution with a mass concentration of 1% at a ratio of material to liquid ratio of 1.0:1.5 (by weight), mix evenly, seal the cooking bag at the level of the liquid level, and place it under pressure for ultrasonic extraction In the kettle; the pressure is 300MPa, the holding time is 8min, and the temperature is 30°C. After the end of the ultra-high pressure, put the material liquid in the sealed bag into the distillation bottle for steam distillation. Deionized water is used as the steam source; the heating temperature is controlled to 102°C to ensure the continuous and stable output of water vapor; the heat preservation temperature of the distillation flask is set to 99°C to control the evaporation rate in the distillation flask; the cooling water circulation device is used to control the flow rate of condensed water and temperature to control the condensation rate; the distillation time is 2h; the first drop of distil...

Embodiment 3

[0049] For fresh Pingyin roses, add a citric acid aqueous solution with a mass concentration of 2% at a ratio of material to liquid ratio of 1.0:2.5 (by weight), mix well, seal the retort bag at the level of the liquid level, and place it under pressure for ultrasonic extraction In the kettle; the pressure is 100MPa, the holding time is 6min, and the temperature is 30°C. After the end of the ultra-high pressure, put the material liquid in the sealed bag into the distillation bottle for steam distillation. Deionized water is used as the steam source; the heating temperature is controlled to 102°C to ensure the continuous and stable output of water vapor; the heat preservation temperature of the distillation flask is set to 99°C to control the evaporation rate in the distillation flask; the cooling water circulation device is used to control the flow rate of condensed water and temperature to control the condensation rate; the distillation time is 2h; the first drop of distillat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com