High-temperature corrosion inhibitor for chlorethylene convertor, preparation thereof and using method thereof

A high-temperature corrosion inhibitor and converter technology, applied in the field of corrosion inhibitors, can solve the problems of poor thermal stability and high-temperature corrosion inhibition, water pollution, corrosion inhibition, and unsatisfactory protection effects, and achieve enhanced high-temperature corrosion inhibition effect. , easily biodegradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

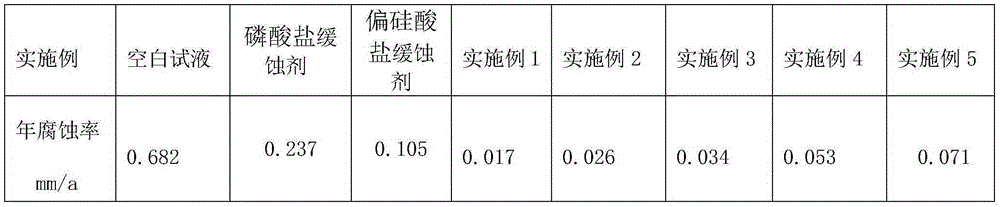

Examples

Embodiment 1

[0030] A sodium lignosulfonate 14g;

[0031] B sodium cardanol sulfonate 56g;

[0032] C deionized water 30g.

[0033] At room temperature, add the deionized water of the above weight into the mixing tank with a stirrer, start stirring, add the sodium lignosulfonate and sodium cardanol sulfonate of the above weight successively, stir for 1 hour after feeding, filter The corrosion inhibitor is produced immediately after discharge.

Embodiment 2

[0035] A sodium lignosulfonate 20g;

[0036] Magnesium Lignosulfonate 11g

[0037] B sodium cardanol sulfonate 49g;

[0038] C deionized water 20g.

[0039] At room temperature, add the deionized water of the above weight into the mixing kettle with a stirrer, start stirring, add the sodium lignosulfonate, magnesium lignosulfonate and sodium cardanol sulfonate of the above weight successively, and the feeding is completed After stirring for 1 hour, the material was filtered and discharged to obtain the corrosion inhibitor.

Embodiment 3

[0041] A sodium lignosulfonate 35g;

[0042] B sodium cardanol sulfonate 17g;

[0043] Magnesium cardanol sulfonate 18g;

[0044] C deionized water 30g.

[0045] At room temperature, add the deionized water of the above weight into the mixing kettle with a stirrer, start stirring, and add the sodium lignosulfonate, sodium cardanol sulfonate and magnesium cardanol sulfonate of the above weight successively, and the feeding is completed After stirring for 1 hour, the material was filtered and discharged to obtain the corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com