SERS substrate loaded with noble metal nanoclusters with 3D network structure and preparation method

A network structure, precious metal technology, applied in measuring devices, instruments, material analysis by optical means, etc., can solve the problems of easy environmental pollution by surfactants and reducing agents, loss of SERS activity, complex preparation process, etc. The effect of clinical biomedical testing, less time-consuming and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

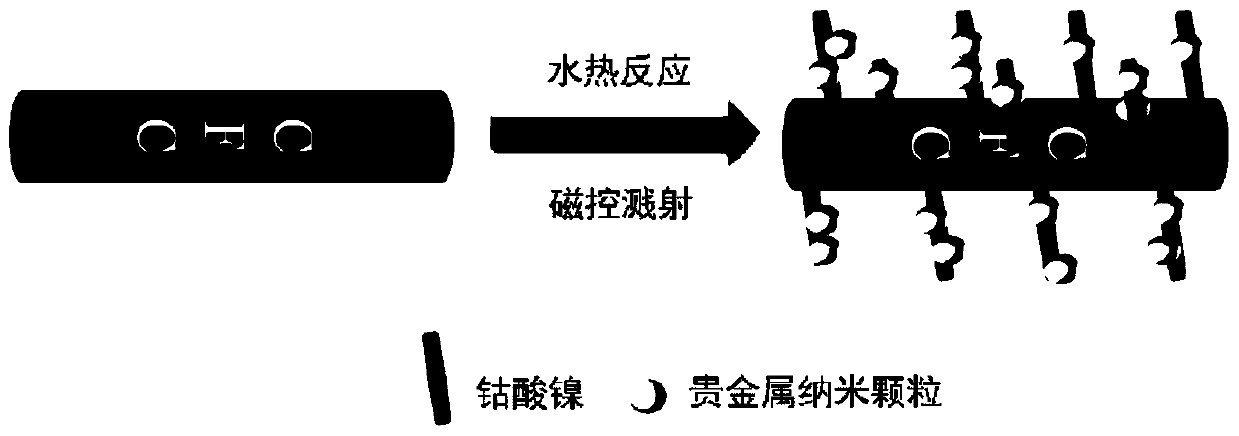

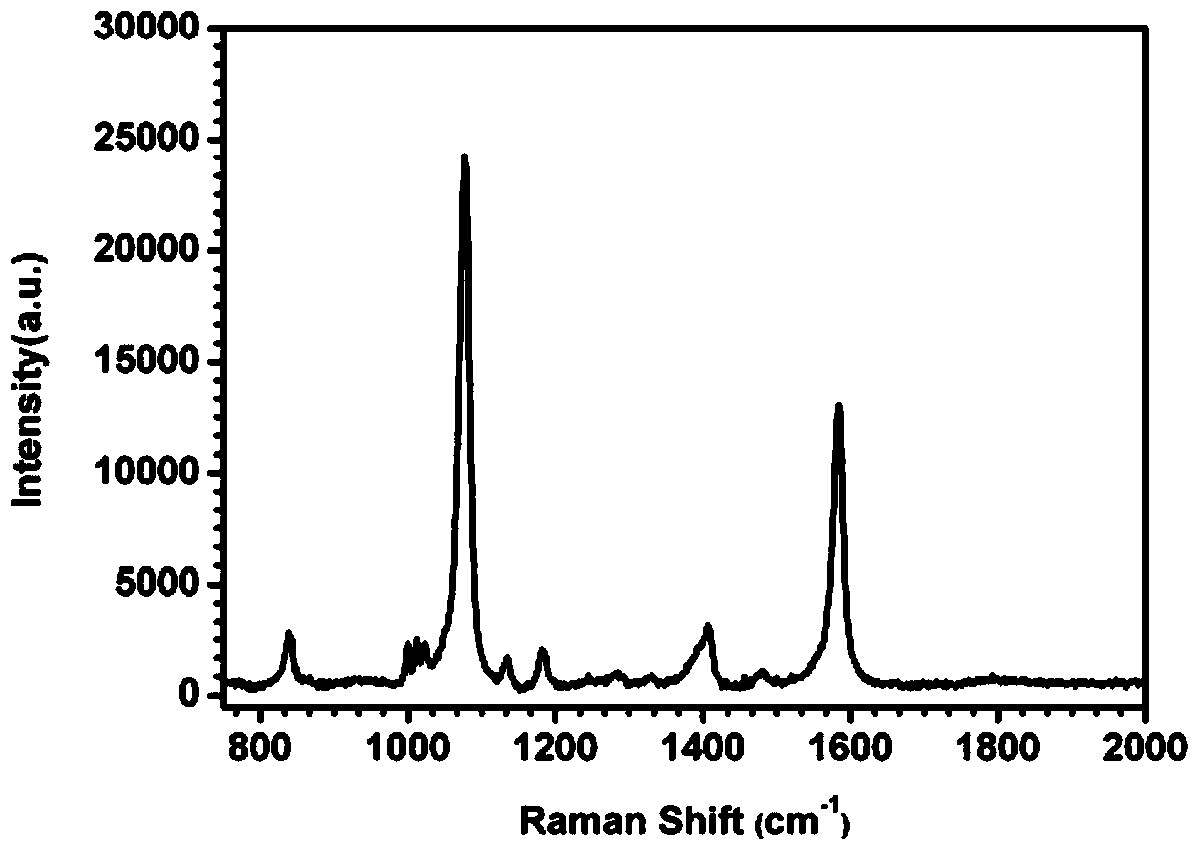

[0022] Example 1 Preparation of a SERS substrate loaded with gold nanoclusters with a 3D network structure

[0023] The preparation method of the SERS substrate loaded with gold nanoclusters with a 3D network structure comprises the following steps:

[0024] Carbon fibers loaded with nickel cobalt oxide nanorods (i.e. flexible carbon cloth loaded with periodic 3D network three-dimensional structure nickel cobalt oxide) were prepared by hydrothermal reaction method, so that the nickel cobalt oxide nanorods grew into regular periodicity on the carbon fibers 3D mesh structure. The specific process is as follows: ultrasonically wash the carbon fibers in acetone, absolute ethanol and deionized water for 20-30 minutes respectively, and then dry them in a vacuum oven at 60°C for 12 hours; place the dried carbon fibers in a high-pressure reactor, Salt, nickel salt and ammonium fluoride were dissolved in deionized water at a molar ratio of 1:2:6 and injected into the above-mentioned h...

Embodiment 2

[0028] Example 2 Preparation of a SERS substrate loaded with silver nanoclusters with a 3D network structure

[0029] The preparation method of the SERS substrate loaded with silver nanoclusters with a 3D network structure comprises the following steps:

[0030] Carbon fibers loaded with nickel cobaltate nanorods (that is, carbon fibers loaded with periodic 3D network three-dimensional structure nickel cobaltate) were prepared by hydrothermal reaction method, so that nickel cobaltate nanorods grew into regular periodic 3D networks on carbon fibers Like structure, this method is described with embodiment 1.

[0031] The above-mentioned carbon fibers loaded with nickel cobaltate nanorods were placed in a radio frequency magnetron sputtering system, and the sputtering working pressure was controlled at 0.6Pa, the sputtering power was 80W, and the sputtering speed was The sputtering time was 80s, the sputtering thickness was 50nm, and the rotation speed was 15rpm. By sputtering ...

Embodiment 3

[0034] Example 3 Preparation of a SERS substrate loaded with copper nanoclusters with a 3D network structure

[0035] The preparation method of the SERS substrate loaded with copper nanoclusters with a 3D network structure comprises the following steps:

[0036] Carbon fibers loaded with nickel cobaltate nanorods (that is, carbon fibers loaded with periodic 3D network three-dimensional structure nickel cobaltate) were prepared by hydrothermal reaction method, so that nickel cobaltate nanorods grew into regular periodic 3D networks on carbon fibers Like structure, this method is described with embodiment 1.

[0037] The above-mentioned carbon fibers loaded with nickel cobalt oxide nanorods were placed in a radio frequency magnetron sputtering system, and the sputtering working pressure was controlled at 0.8Pa, the sputtering power was 100W, and the sputtering speed was The sputtering time was 100s, the sputtering thickness was 180nm, and the rotation speed was 18rpm. By sputt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com